A Low-Frequency Large-Displacement Angle Vibration Table

An angular vibration table and large displacement technology, which is applied in vibration testing, measuring devices, instruments, etc., can solve the problems of large output waveform distortion and small output angular displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

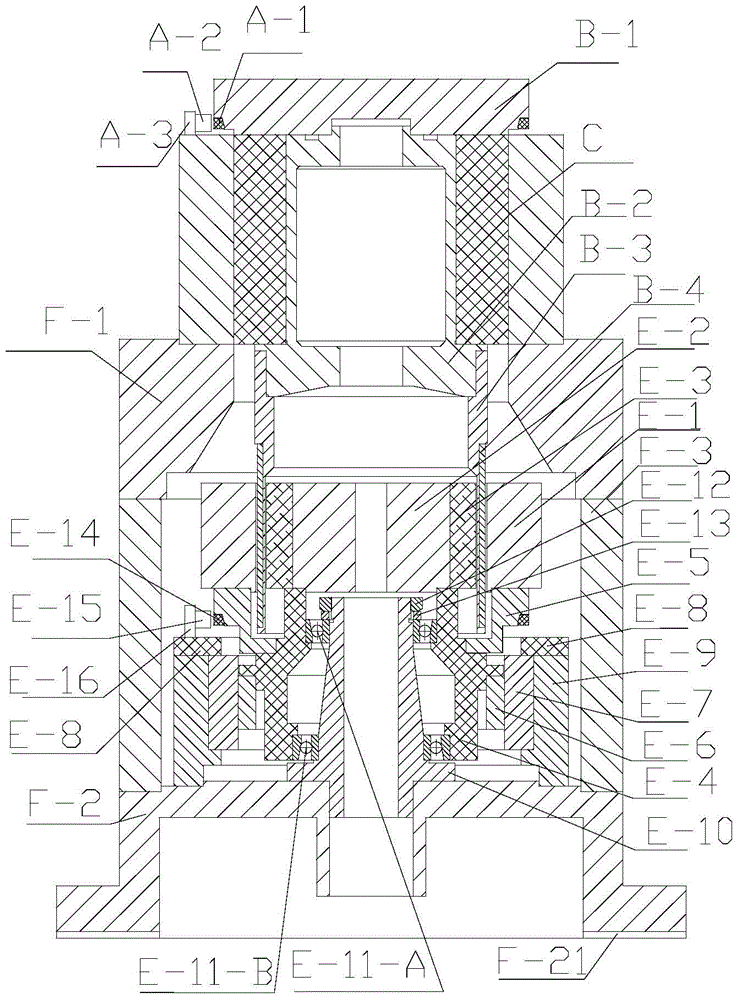

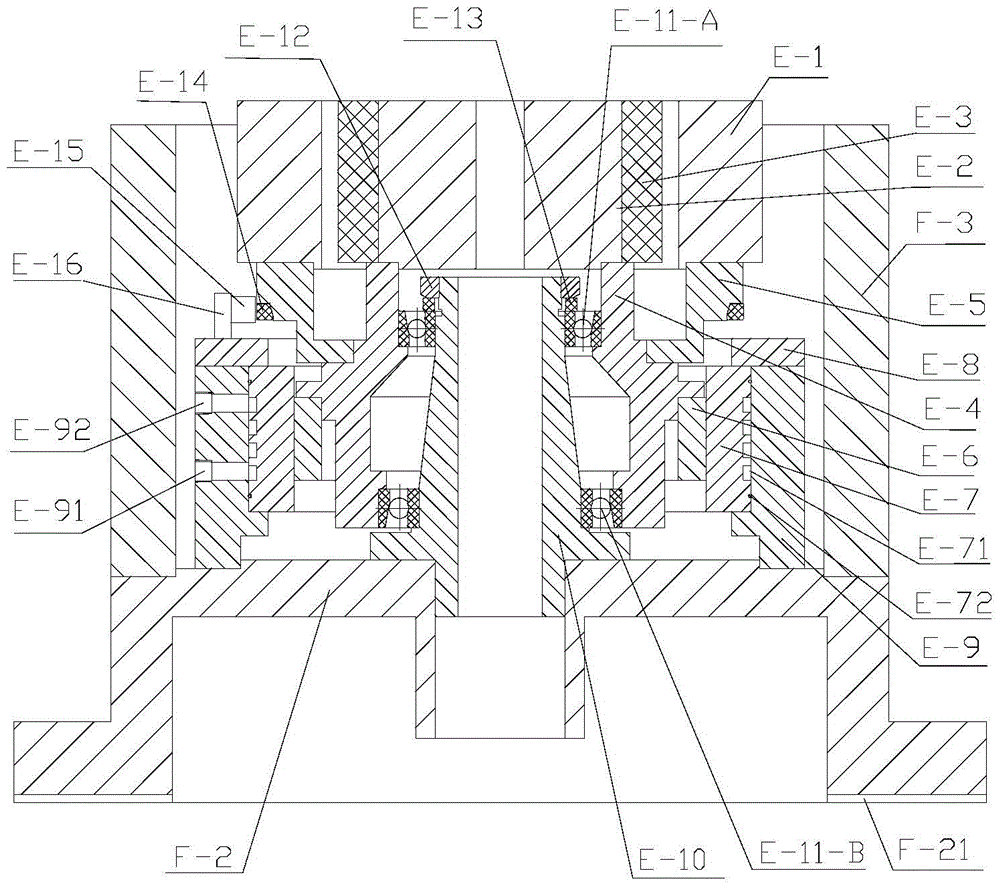

[0056] refer to Figure 1-6

[0057] Such as figure 1 As shown, a low-frequency large-displacement-angle vibrating table includes a housing, a worktable B-1, a spindle B-2 that drives the worktable B-1 to rotate, a moving coil assembly, a magnetic circuit assembly, a motor that drives the magnetic circuit assembly to rotate, and Its closed-loop control components, electro-viscoelastic feedback control components, air bearings and angular displacement sensors;

[0058] The main shaft B-2 is fixedly connected with the moving coil assembly, and the motor rotor E-6 is fixedly connected with the magnetic circuit assembly through the connecting piece;

[0059] The moving coil assembly includes a moving coil base B-3 connected to the main shaft B-2 and a coil B-4 wound on the moving coil base B-3, and the moving coil base B-3 is fixedly connected to the main shaft B-2;

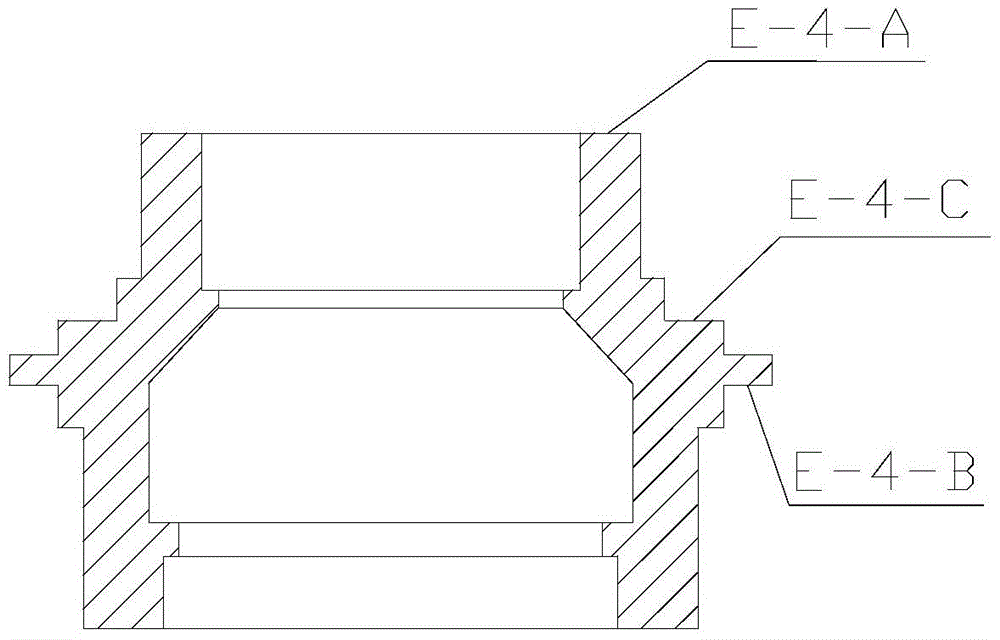

[0060] The magnetic circuit assembly includes the magnetic ring E-1, the central magnetic pole E-2 and the magn...

Embodiment 2

[0079] The difference between this embodiment and the first embodiment lies in the specific structure of the air bearing, and the structure of other components except the air bearing is the same as that of the first embodiment.

[0080] Specifically: if Figure 7 As shown, the air bearing includes bearing seat C-1 and bearing body C-2, the main shaft B-2 is socketed in the bearing body C-2, the bearing body C-2 is socketed in the bearing seat C-1, and the bearing seat C -1 is fixed with the bearing body C-2, and the bottom of the main shaft B-2 is provided with a step matching with the bearing body C-2;

[0081] The outer surface of the bearing body C-2 is provided with a circular air intake groove C-21, and the bearing seat C-1 is provided with an air intake hole C-11 communicating with the air intake groove C-21, and the bearing body C -2 is provided with the radial air guide hole between the bearing body C-2 and the main shaft B-2, which guides the gas to the upper axial a...

Embodiment 3

[0092] refer to Figure 8 , 9 、10

[0093] The difference between this embodiment and Embodiment 1 lies in the coil of the moving coil assembly, and the structure of other components except the coil is the same as that of Embodiment 1.

[0094] Such as Figure 8 As shown, the coil B-4 of the moving coil assembly covers the outer surface of the moving coil base B-3. Such as Figure 9 As shown, the coil includes a coil winding B-4-1 and an insulating layer B-4-3, the coil winding B-4-1 and the insulating layer B-4-3 are arranged at intervals, and the coil winding B-4-1 has at least one layer , the insulating layer B-4-3 is made of epoxy resin glue and glass cloth, and the insulating layer completely covers the coil winding B-4-1 inside. Such as Figure 10As shown, the coil winding includes the first coil B-4-1-1 and the second coil B-4-1-2, the first coil B-4-1-1 is wound counterclockwise from inside to outside, the second coil B -4-1-2 Winding clockwise from outside to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com