A Low Pressure Hydrogen Flame Ionization Detector

A hydrogen flame and ionization technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems affecting the detection effect and stability, affecting the sensitivity of the detector, large signal flicker noise, etc., to achieve compact structure, space structure Economical and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

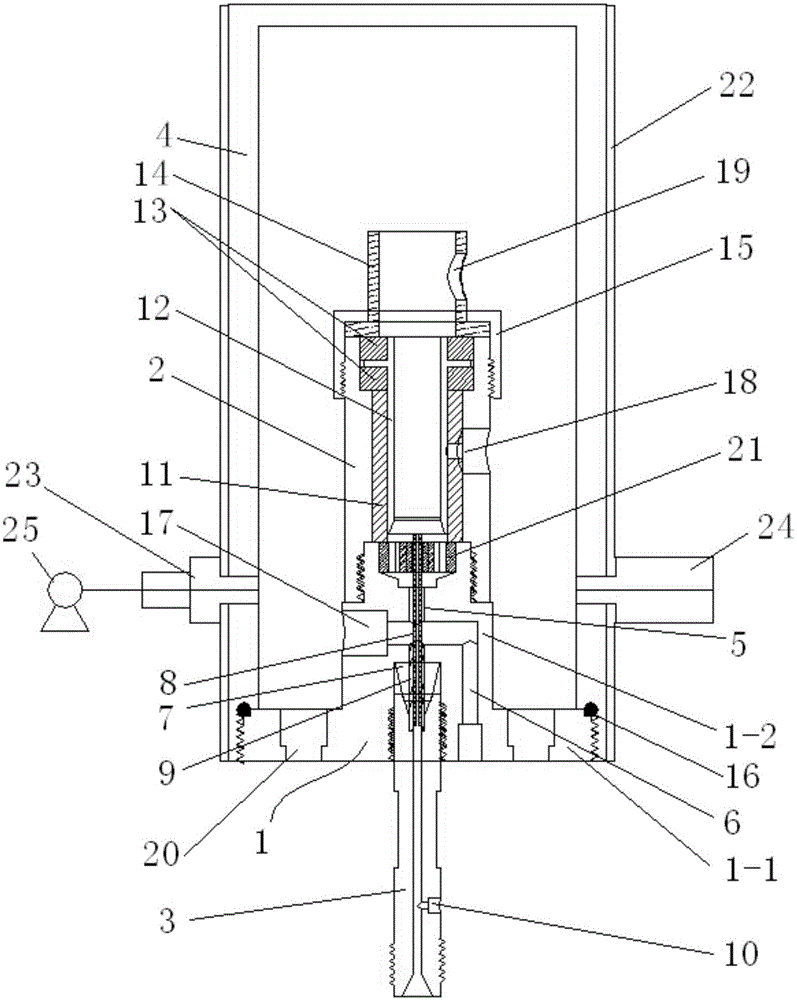

[0014] like figure 1 As shown, the present invention includes a lower casing 1 , an upper casing 2 , an air intake pipe 3 and a sealing cylinder 4 .

[0015] The lower casing 1 includes a disc base 1-1 with a large diameter and a cylindrical base 1-2 with a small diameter integrally arranged, wherein the cylindrical base 1-2 is coaxially arranged on the top of the disc base 1-1. An external thread is provided on the upper end of the cylindrical base 1-2. Have a cylindrical groove body at the top center of cylindrical base 1-2, have another cylindrical groove body at the bottom center of disc base 1-1, be positioned at the groove body of the bottom of disc base 1-1 Internal threads are provided on the side walls. A through hole 5 penetrating through the center of the lower casing 1 is provided between the two grooves. An air passage 6 communicating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com