Piezoresistive acceleration sensor and manufacturing method thereof

An acceleration sensor and piezoresistive technology, which is applied in the field of sensors, can solve the problems of low sensitivity of piezoresistive sensors, high requirements for packaging vacuum degree, and easy to be affected by air resistance, etc., to achieve simple structure, ensure accuracy, and vacuum degree The effect of request reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

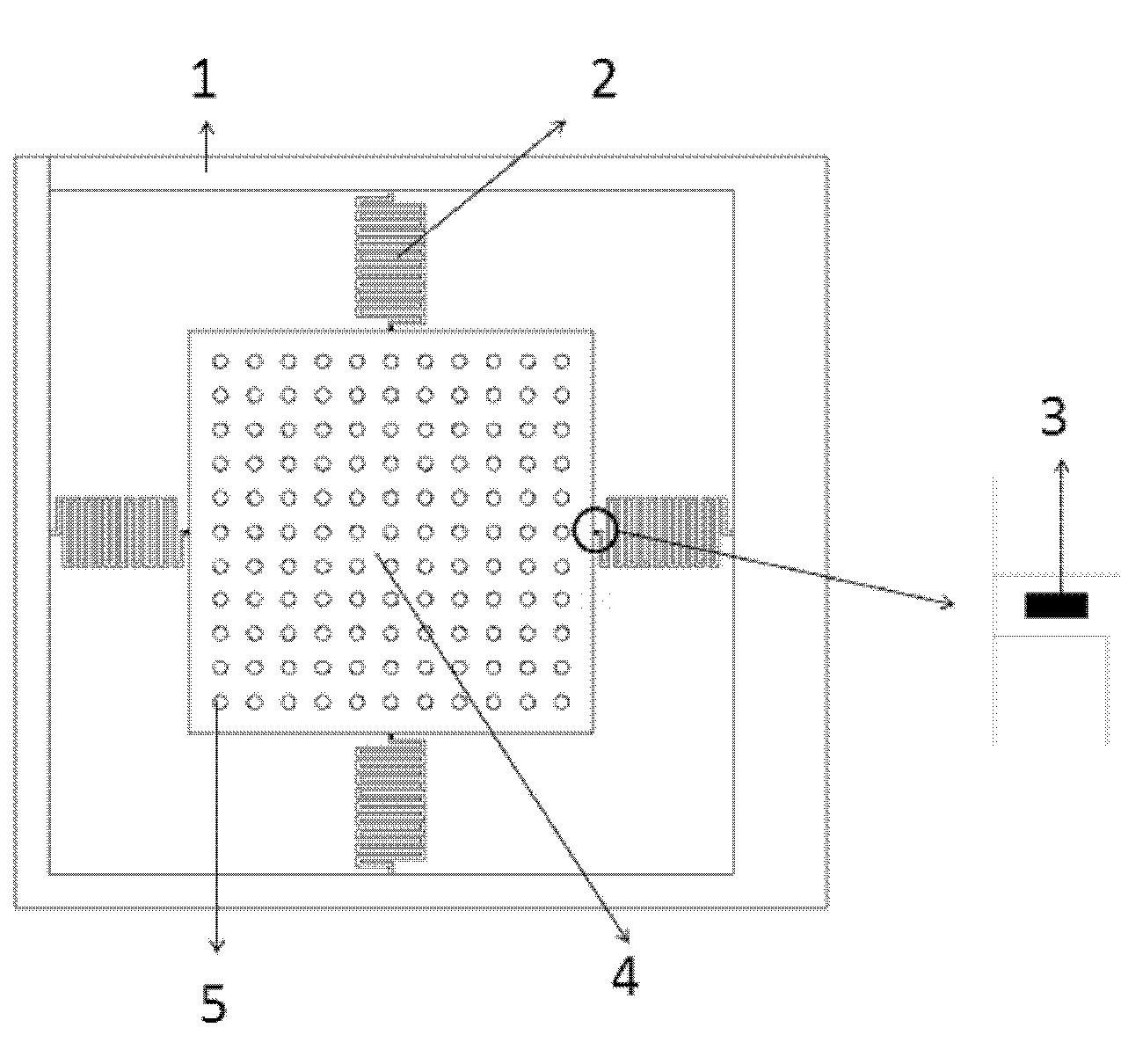

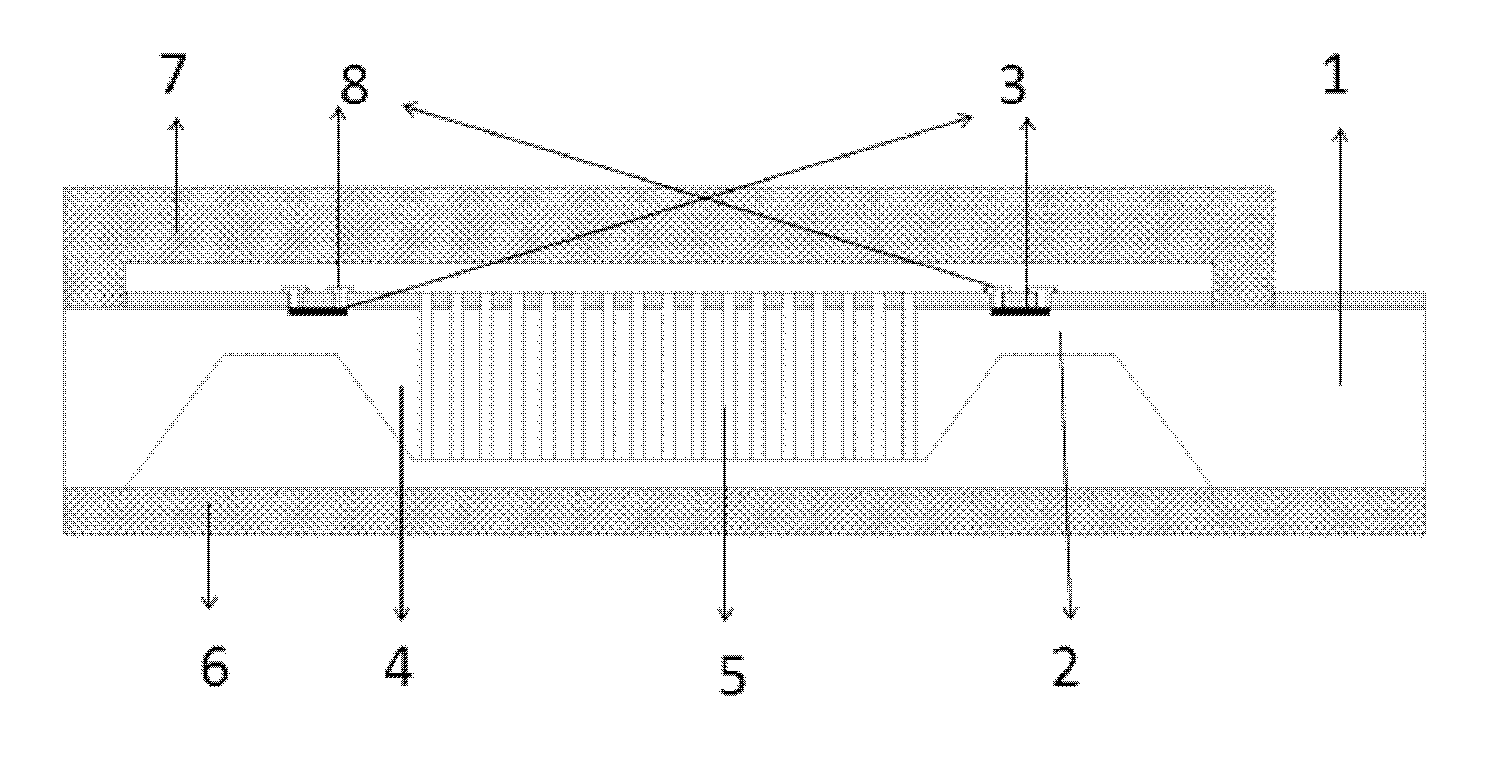

[0034] figure 1 It is the top view of piezoresistive acceleration sensor of the present invention, as figure 1 As shown, the piezoresistive acceleration sensor of the present invention includes a supporting frame 1 , four snake-shaped elastic cantilever arms 2 , a piezoresistor 3 , a mass 4 , a damping hole 5 , a glass substrate 6 and a glass cover 7 . The support frame 1 supports the mass block 4 through a serpentine elastic cantilever arm, and the lower surface of the mass block 4 is higher than the lower surface of the support frame 1, which facilitates the mass block to move up and down under the action of inertia; the elastic cantilever arm 2 adopts a serpentine structure, which can The length of the beam is longer, the response to acceleration is more sensitive, and the sensitivity of the sensor can be effectively increased; the piezoresistor 3 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap