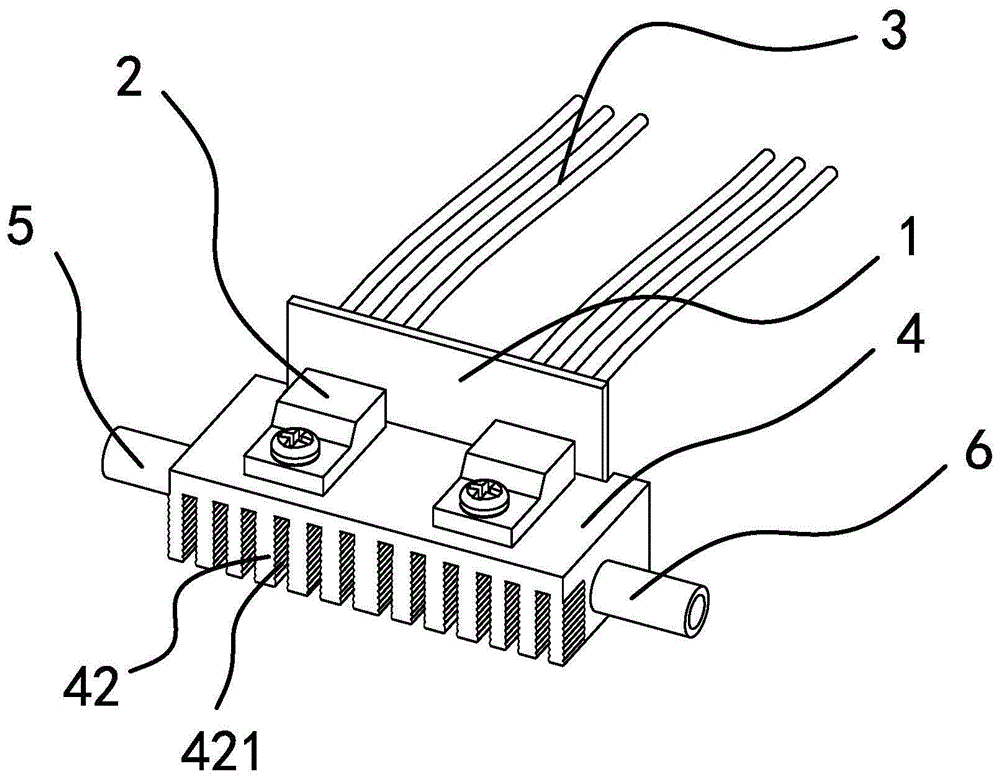

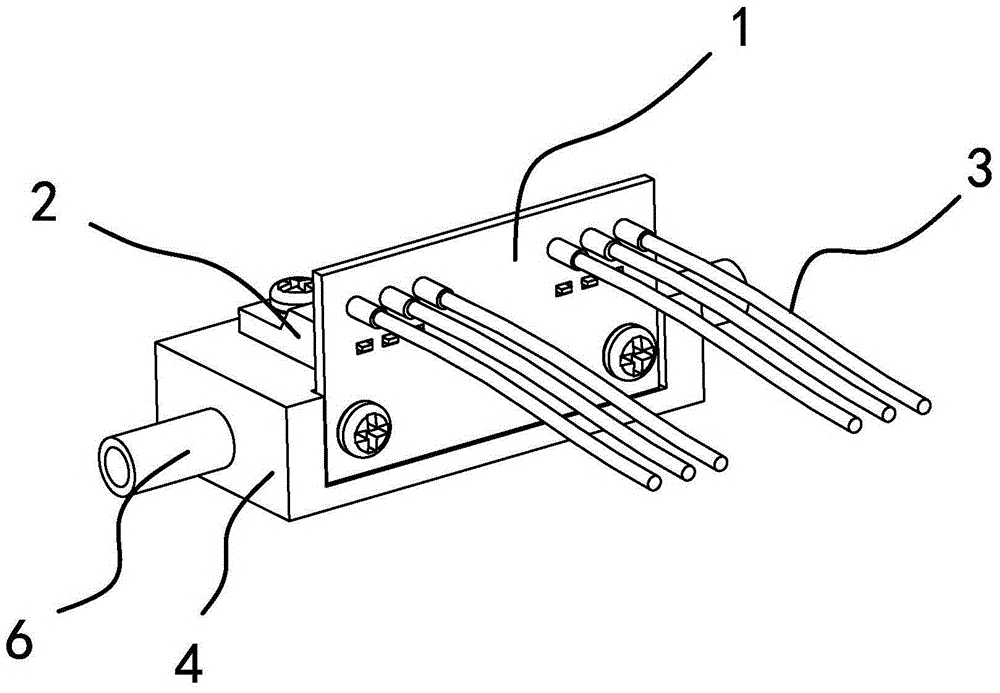

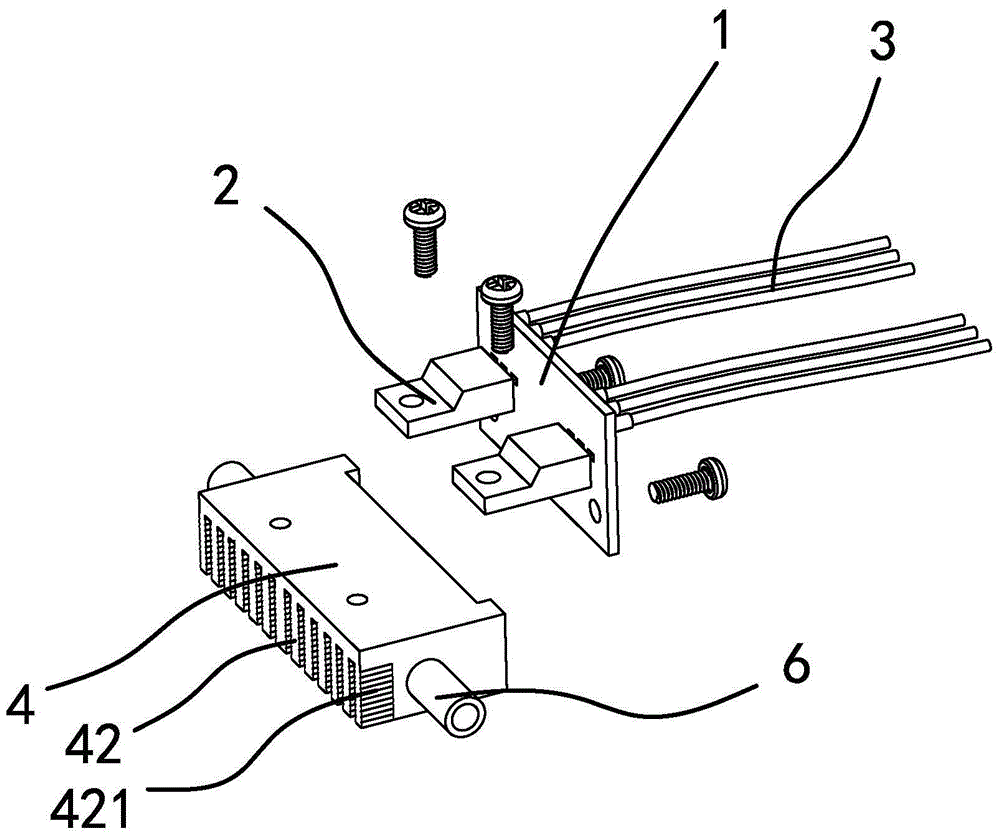

A thyristor cooling device in a coffee machine

A technology for a heat sink and a coffee machine, applied in the field of heat sinks and thyristor heat sinks, can solve problems such as uncontrolled, damaged thyristor, and occupancy of heat sinks, and achieve the effects of relieving heating pressure and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Pre-treatment: Treat the cooling fins with an alkaline chemical degreasing solution at 55°C for 2 minutes, then perform alkali etching in 40g / L NaOH solution at 50°C for 1min, and then in 10mL / L H 2 SO 4 and 6mL / L of HNO 3 Neutralize the residual alkali in the acid etching solution, take it out after 1 minute, wash it, and dry it; the chemical composition of the degreasing solution is: NaOH: 8g / L, NaOH: 8g / L, Na 2 CO 3 : 20g / L, Na 3 PO 4 .12H 2 O: 8g / L, surfactant 1g / L;

[0041] Oxidation coloring: oxidize the pre-treated cooling fins in chromate at 65°C for 5 minutes, and then perform blackening treatment; the chemical composition of chromate is: Na 2 CrO 4 : 15g / L, Na 2 CO 4 : 3g / L, NaOH: 3g / L, NaOH 3 PO 4 : 9g / L; Co(CH 3 COO) 2 : 17g / L, oxidant KMnO 4 : 7g / L, catalyst NiSO 4 : 1.0g / L, with 5g / L HNO 3 Adjust the pH to 4-5, the temperature is 75°C, and blacken for 10 minutes;

[0042] Sealing: The colored heat dissipation fins are sealed by hydrolytic ...

Embodiment 2

[0044] Pre-treatment: Treat the cooling fins with an alkaline chemical degreasing solution at 58°C for 3 minutes, then perform alkali etching in 45g / L NaOH solution at 50-60°C for 1min, and then in 15mL / L H 2 SO 4 and 8mL / L of HNO 3 Neutralize the residual alkali in the acid etching solution, take it out after 2 minutes, wash it, and dry it; the chemical composition of the degreasing solution is: NaOH: 9g / L, NaOH: 9g / L, Na 2 CO 3 : 22g / L, Na 3 PO 4 .12H 2 O: 10g / L, surfactant 1g / L,

[0045] Oxidation coloring: the pre-treated cooling fins were oxidized in chromate at 70°C for 7 minutes, and then blackened; the chemical composition of chromate was: Na 2 CrO 4 : 18g / L, Na 2 CO 4 : 3.5g / L, NaOH: 4g / L, NaOH 3 PO 4 : 9.5g / L; Co(CH 3 COO) 2 : 19g / L, oxidant KMnO 4 : 8g / L, catalyst NiSO 4 : 1.6g / L, with 8g / L HNO 3 Adjust the pH to 4-5, the temperature is 80°C, and the blackening treatment takes 13 minutes;

[0046] Sealing: The colored heat dissipation fins are seale...

Embodiment 3

[0048] Pre-treatment: Treat the cooling fins with alkaline chemical degreasing solution at 60°C for 4 minutes, then perform alkaline etching in 50g / L NaOH solution at 60°C for 2 minutes, and then in 20mL / L H 2 SO 4 and 10mL / L of HNO 3 Neutralize the residual alkali in the acid etching solution, take it out after 3 minutes, wash it, and dry it; the chemical composition of the degreasing solution is: NaOH: 10g / L, Na 2 CO 3 : 23g / L, Na 3 PO 4 .12H 2 O: 12g / L, surfactant 1g / L;

[0049] Oxidation coloring: oxidize the pre-treated cooling fins in chromate at 75°C for 8 minutes, and then perform blackening treatment; the chemical composition of chromate is: Na 2 CrO 4 : 20g / L, Na 2 CO 4 : 4g / L, NaOH: 5g / L, NaOH 3 PO 4 : 10g / L; Co(CH 3 COO) 2 : 20g / L, oxidant KMnO 4 : 10g / L, catalyst NiSO 4 : 2.2g / L, with 10g / L HNO 3 Adjust the pH to 4-5, the temperature is 85°C, and the blackening treatment is 15 minutes;

[0050] Sealing: The colored heat dissipation fins are sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com