Cleaning machine for various types of bearings

A bearing cleaning, multi-model technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of large time consumption and labor costs, inconsistent cleanliness of workpieces, low cleanliness, etc. , to achieve the effect of fast cleaning speed, good cleaning effect and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

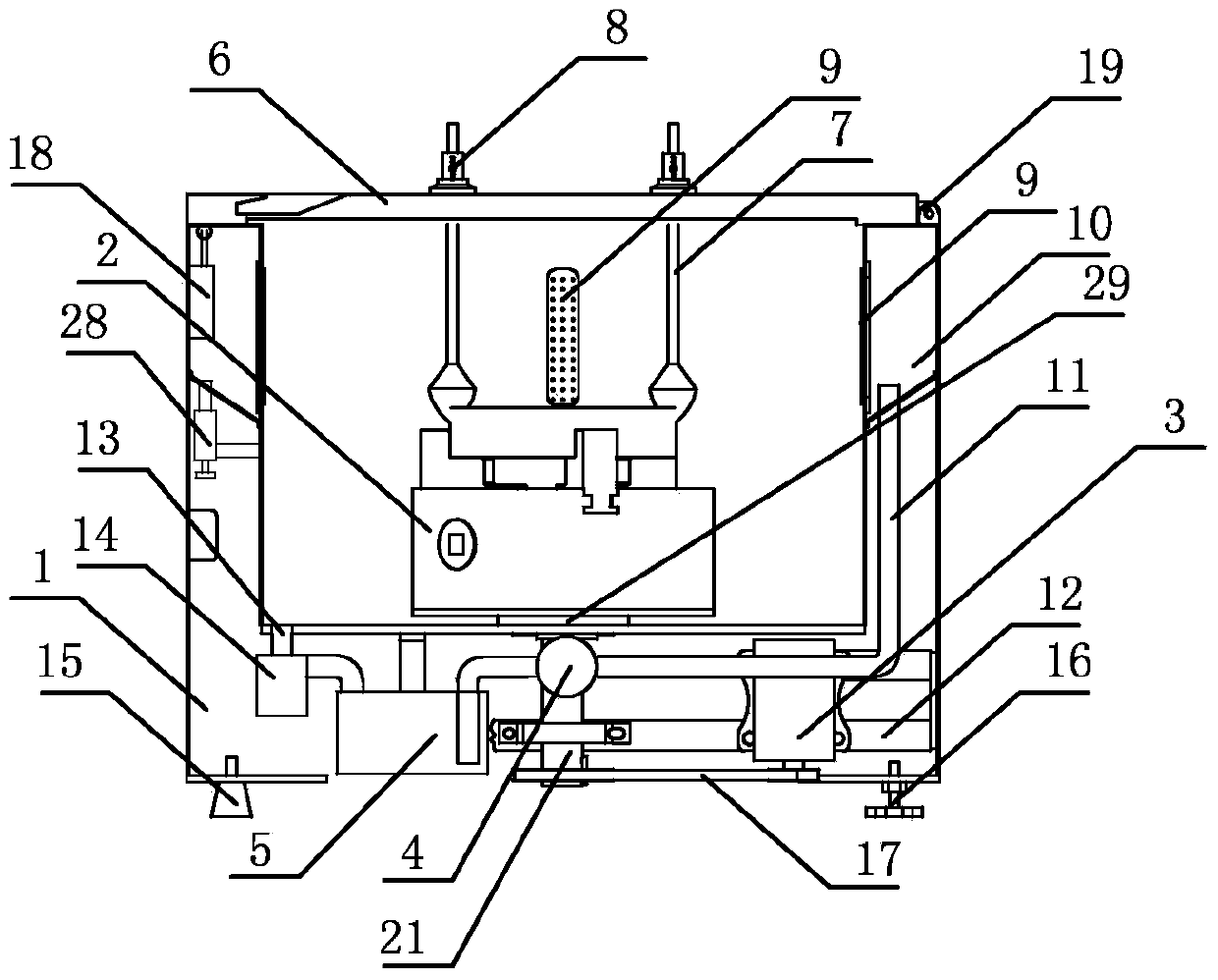

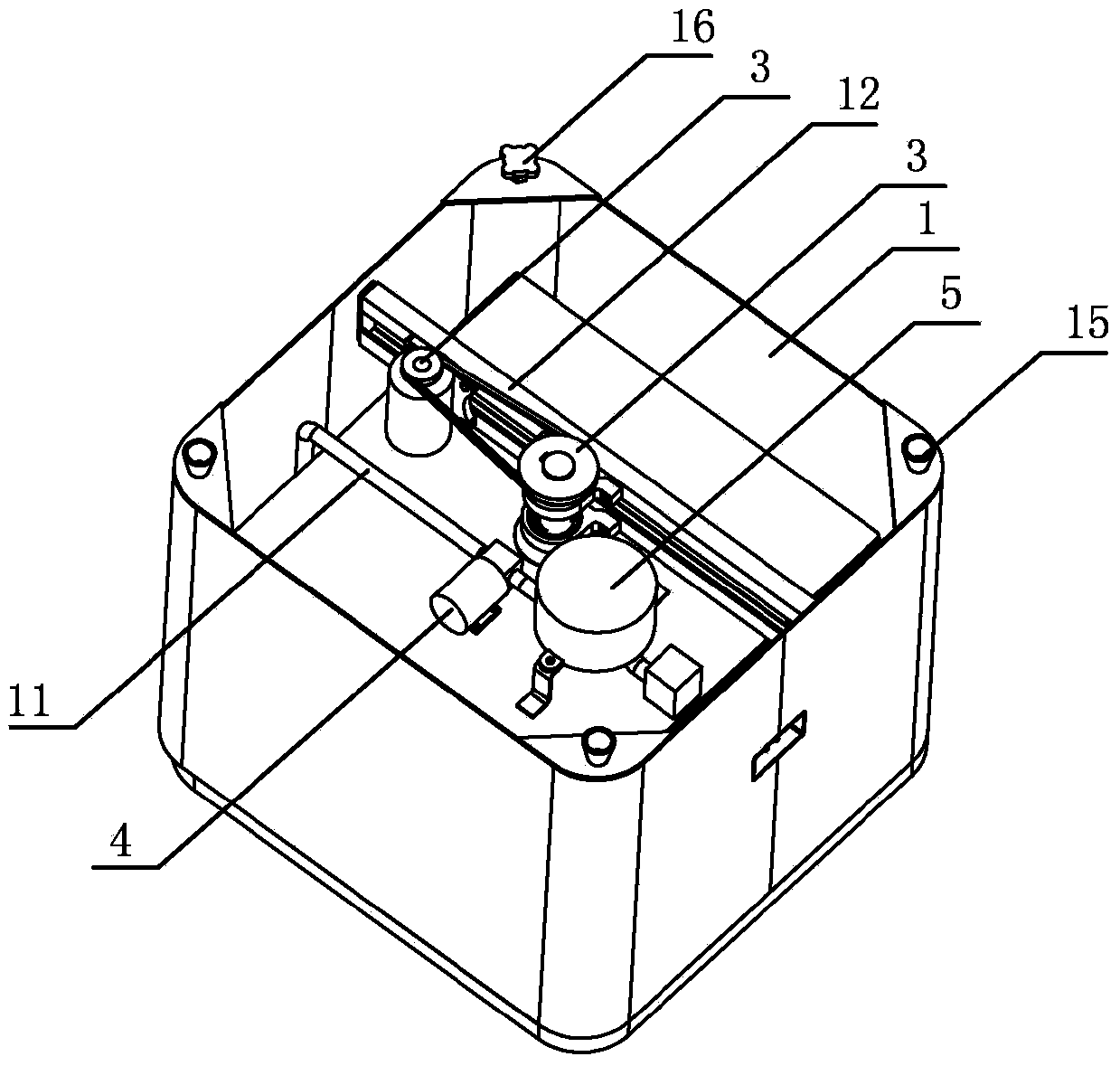

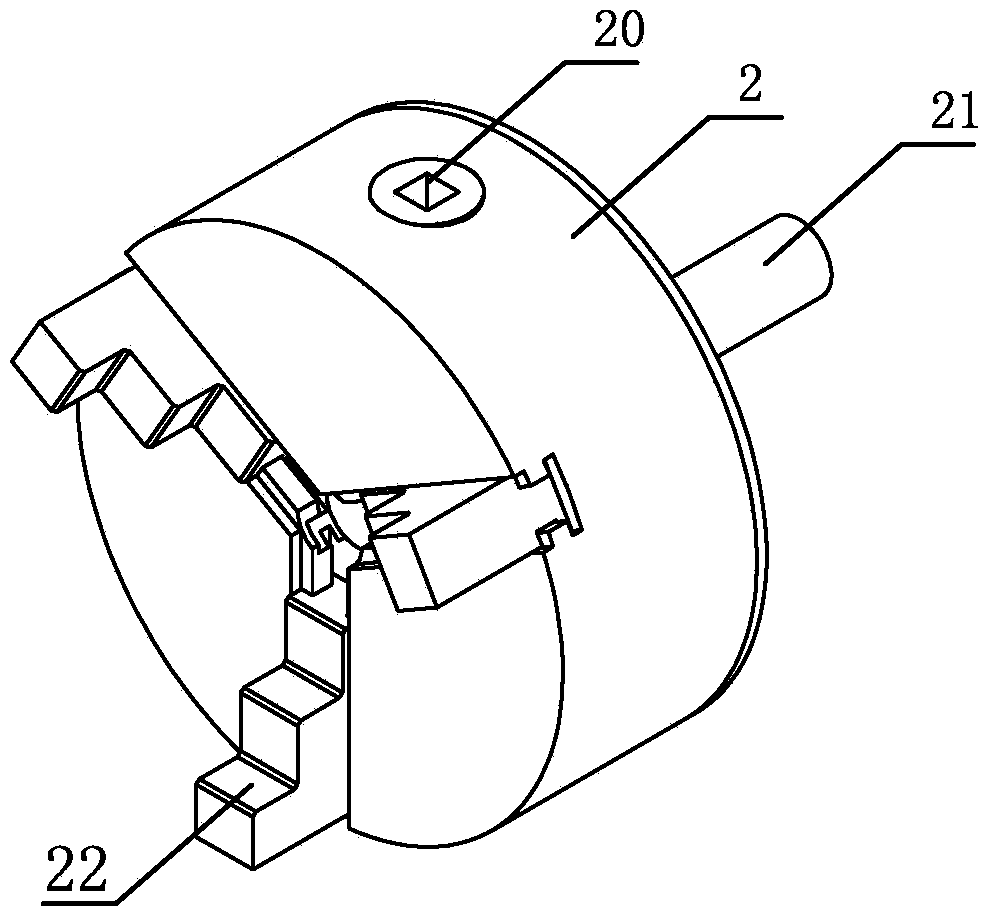

[0026] Embodiment: multi-type bearing cleaning machine, which mainly includes: chassis 1, concentric holder 2, spindle motor 3, micro water pump 4, liquid storage tank 5, chassis cover 6, brush shaft 7, lock screw 8, spray Plate 9, liquid injection chamber 10, spray pipe 11, bracket fixing plate 12, liquid recovery hole 13, liquid filter 14, height fixed foot 15, height adjustable foot 16, belt 17, limit switch 18, hinge 19, Small bevel gear 20, rotating shaft 21, clip 22, large bevel gear 23, gear plate 24, brush ball 25, lower rubber ring 26, upper rubber ring 27, overflow valve 28, sealing sleeve 29;

[0027] The bracket fixing plate 12 at the bottom of the cabinet 1 is fixed with a spindle motor 3, and the spindle motor 3 is connected to the rotating shaft 21 through a belt 17; the rotating shaft 21 is fixed at the center position of the concentric holder 2, and the concentric holder 2 is provided with a large bevel gear 23; the upper surface of the large bevel gear 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com