An automatic tin scraper and soldering device

A tin scraping and automatic technology, applied in the direction of tin feeding device, auxiliary device, welding equipment, etc., can solve the problems of non-standard soldering time, non-standard tin scraping action, non-standard soldering height, etc., to achieve good soldering effect and good tin scraping The effect is ideal and the tin scraping action is standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

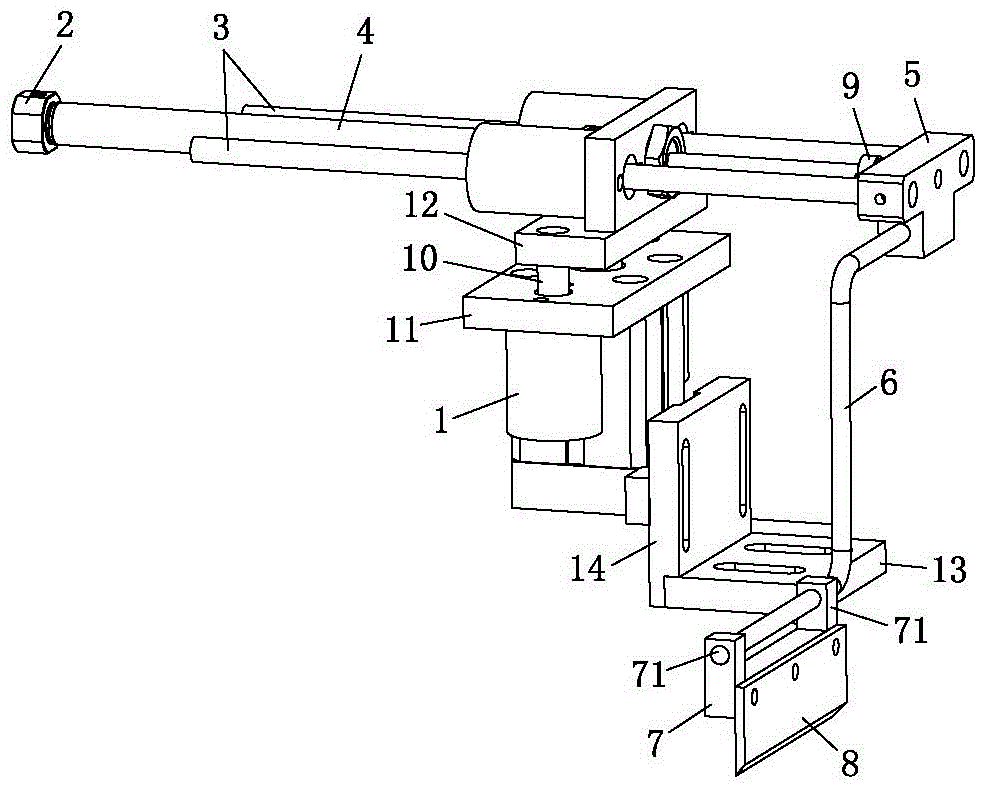

[0046] See figure 1 . An automatic tin scraping machine in this embodiment includes a time relay, a first cylinder 1 and a second cylinder 2 controlled by the time relay, and a tin scraping mechanism drivingly connected to the second cylinder 2;

[0047] The first cylinder 1 and the second cylinder 2 are driven and connected, and the first cylinder 1 makes the second cylinder 2 move up and down, and then the second cylinder 2 drives the tin scraping mechanism to move up and down;

[0048] The second cylinder 2 is provided with a second cylinder rod 3 and a second cylinder optical axis 4, and the second cylinder rod 3 and the second cylinder optical axis 4 are respectively connected with the tin scraping mechanism, and make the tin scraping mechanism move horizontally. That is, the second cylinder 2 moves the tin scraping mechanism horizontally through the second cylinder rod 3 and the second cylinder optical axis 4 .

[0049] In this embodiment, the tin scraping mechanism in...

Embodiment 2

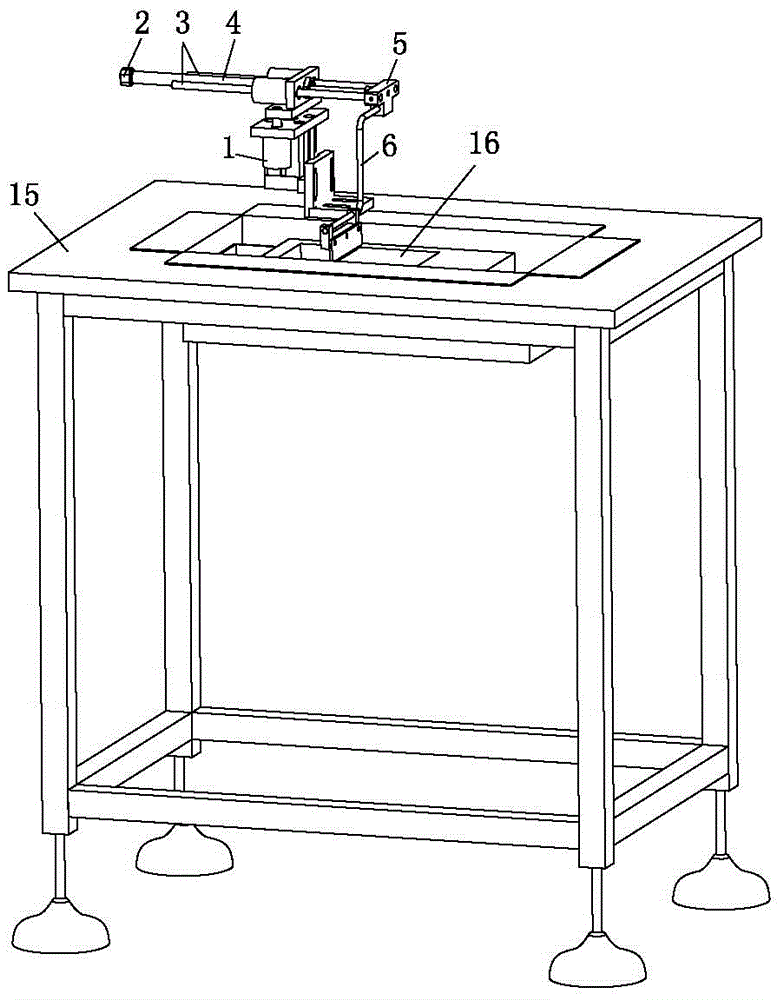

[0058] See figure 2 . A soldering device of this embodiment includes a frame 15, a tin melting furnace 16 arranged on the frame 15, and an automatic tin scraper of the above-mentioned embodiment 1.

[0059] The specific working process of the soldering device is: when the temperature of the tin melting furnace 16 rises to the temperature required for production, the automatic tin scraping machine receives the tin scraping instruction, first, the first cylinder 1 makes the tin scraping bar 8 move upward, That is, the height of the tin scraping bar 8 is raised, and then the second cylinder 2 passes through the second cylinder rod 3 and the second cylinder optical axis 4 to finally make the tin scraping bar 8 move horizontally, and send the tin scraping bar 8 to the designated position . Then, the time relay starts timing and reads the number of seconds. When the specified time is reached, the first cylinder 1 drives the tin scraping bar 8 to make a downward movement, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com