Full-automatic bundling machine for small-bundle wire

A strapping machine, fully automatic technology, applied in the direction of strapping materials, strapping machine parts, paper/cardboard containers, etc. Suitable for automatic binding and other problems, to achieve the effect of saving binding materials, reliable performance and short distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

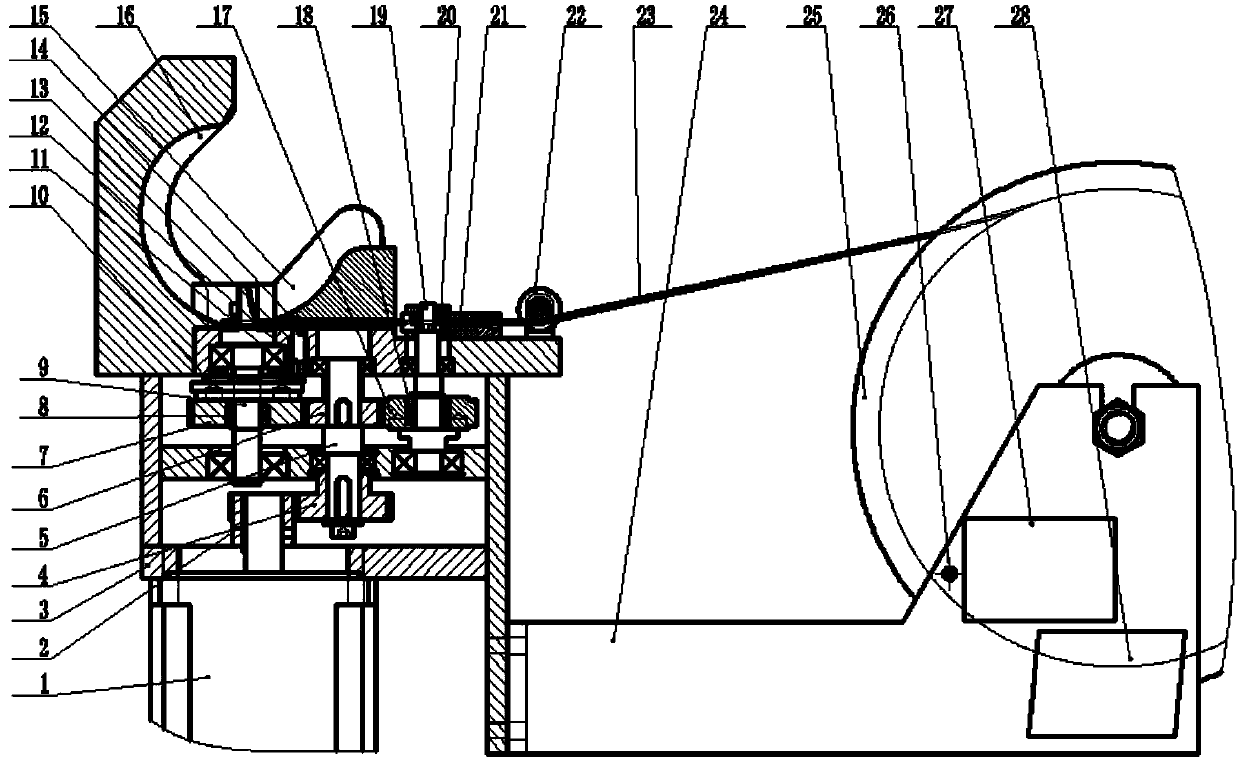

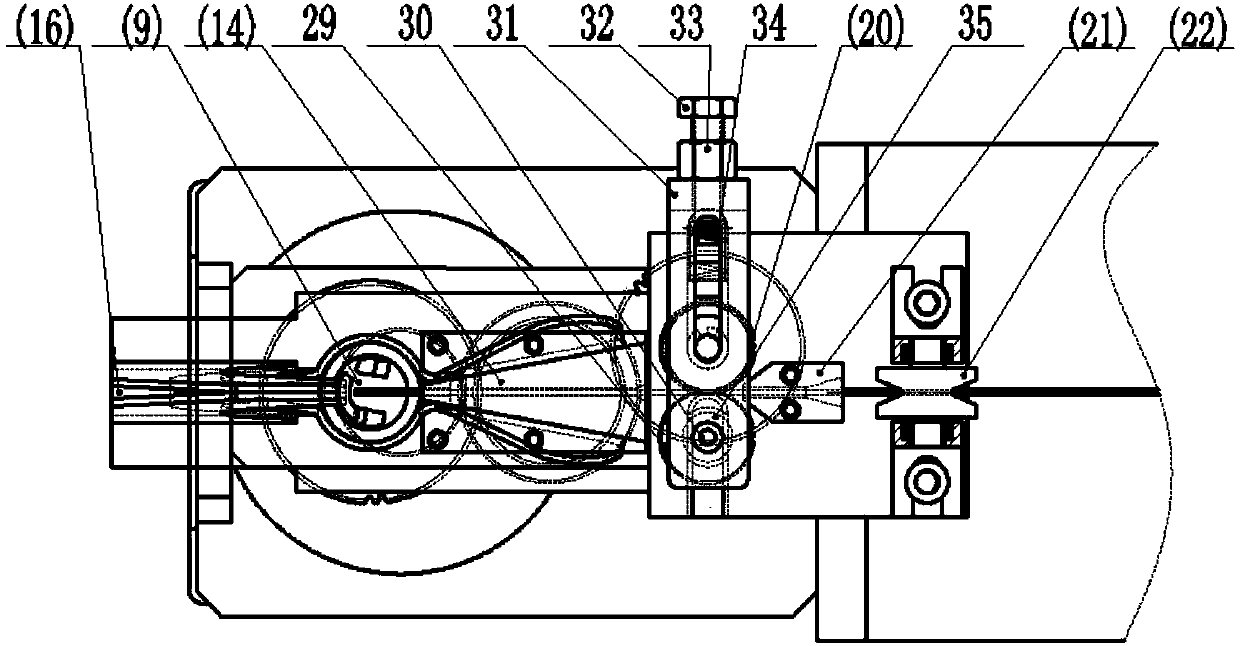

[0029] refer to figure 1 , figure 2 , Fully automatic bundling machine for small bundles of wire, composed of drive control components, transmission components, wire storage components, wire feeding and rounding components, broken wire and knotting components.

[0030] The drive control assembly is located at the bottom of the baler, and consists of a servo motor 1, a servo motor driver 27 and a servo motor controller 28. The output shaft of the servo motor 1 is fixedly connected to the gear 1 2, and the servo motor driver 27 is connected to the servo motor 1 before and after. and servo motor controller 28;

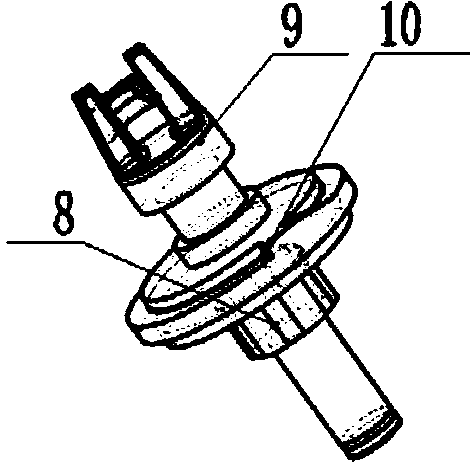

[0031] The transmission assembly is located in the middle of the frame 3 of the baler, including gear one 2, gear two 4, main shaft 5, gear three 6, gear four 7, one-way bearing one 8, knotting shift fork shaft 9, gear five 17, one-way bearing two 18, active...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com