A kind of preparation method of nanometer tio2 microsphere

A microsphere and nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process, high cost, and difficult control of product microscopic shape, and meet the technological conditions Easy to control, low cost, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention is a kind of nano TiO 2 Preparation method of microspheres with TiCl 4 As a raw material, nano-TiO was synthesized at one time by hydrothermal synthesis 2 Microspheres have the advantages of low raw material cost, simple process, and easy control of product shape.

[0027] The method steps are as follows:

[0028] (1) Under the conditions of ice-water bath and magnetic stirring, TiCl 4 The solution was slowly added dropwise into deionized water to prepare TiCl with a concentration of 0.2-1.5 mol / L 4 To the suspension, add 0.0-2.0% surfactant by mass, heat to 50-80°C under stirring condition, keep the temperature for 10-60 min, and continue stirring for 10 min;

[0029] (2) Take the TiCl obtained in step (1) 4 Put the suspension into the polytetrafluoroethylene lining of the stainless steel autoclave; the filling rate is 50-80%, seal it and put it in an oven; react at a constant temperature of 100-155°C for 0.5-10 hours and then cool naturally ...

Embodiment 1

[0037] A kind of nano TiO 2 The preparation method of microsphere, its step is as follows:

[0038] (1) Under the conditions of ice-water bath and magnetic stirring, TiCl 4 The solution was slowly added dropwise into deionized water to make TiCl with a concentration of 0.5mol / L 4 Suspension, heated to 80°C with stirring, kept at constant temperature for 10 minutes, and continued to stir for 10 minutes;

[0039] (2) Take the TiCl obtained in step (1) 4 The suspension was put into the polytetrafluoroethylene lining of the stainless steel autoclave; the filling rate was 60%, and it was sealed and put into an oven; after reacting at a constant temperature of 120°C for 6 h, it was naturally cooled to room temperature; Wash the precipitate repeatedly with water and ethanol, filter or centrifuge until no chloride ions are detected in the filtrate, and dry at 80°C.

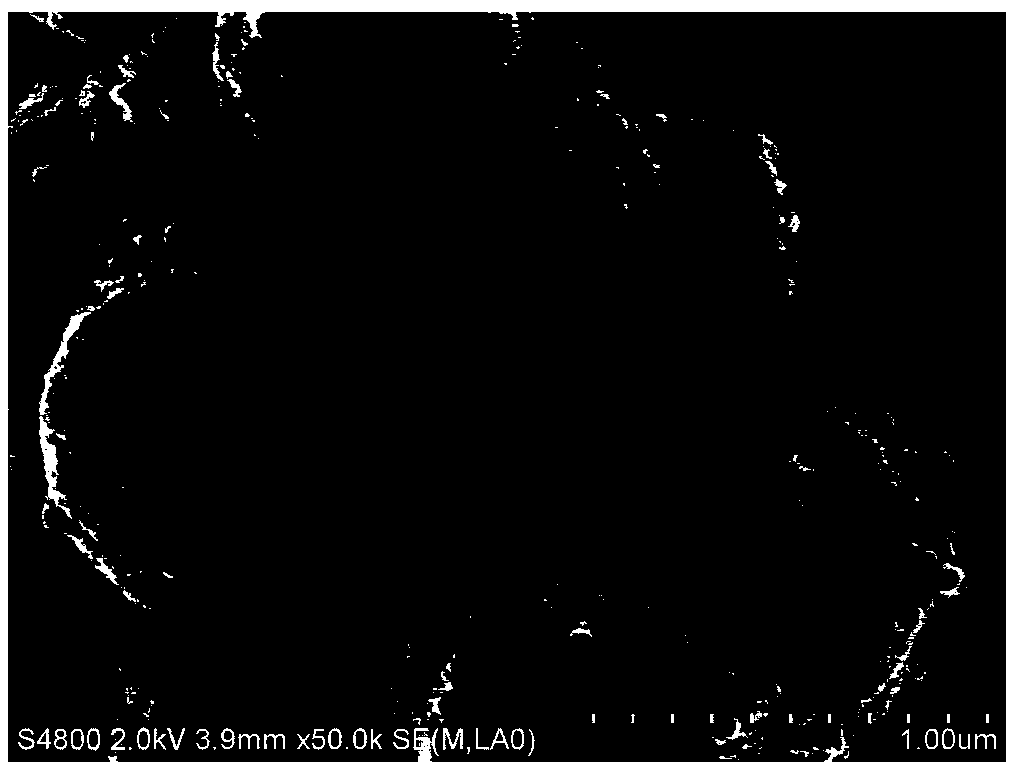

[0040] Nano-TiO 2 The microspheres are rutile TiO 2 , the microsphere is composed of radial nanorods with a diame...

Embodiment 2

[0042] A kind of nano TiO 2 The preparation method of microsphere, its step is as follows:

[0043] (1) Under the conditions of ice-water bath and magnetic stirring, TiCl 4 The solution was slowly added dropwise into deionized water to make TiCl with a concentration of 1.5mol / L 4 To the suspension, add 1.0% by mass surfactant polyethylene glycol 4000, heat to 50°C under stirring, keep the temperature constant for 60 minutes, and continue stirring for 10 minutes;

[0044] (2) Take the TiCl obtained in step (1) 4The suspension was put into the polytetrafluoroethylene lining of the stainless steel autoclave; the filling rate was 80%, and it was sealed and placed in an oven; after reacting at a constant temperature of 155°C for 0.5 h, it was naturally cooled to room temperature; Wash the precipitate repeatedly with water and ethanol, filter or centrifuge until no chloride ions are detected in the filtrate, and dry at 120°C.

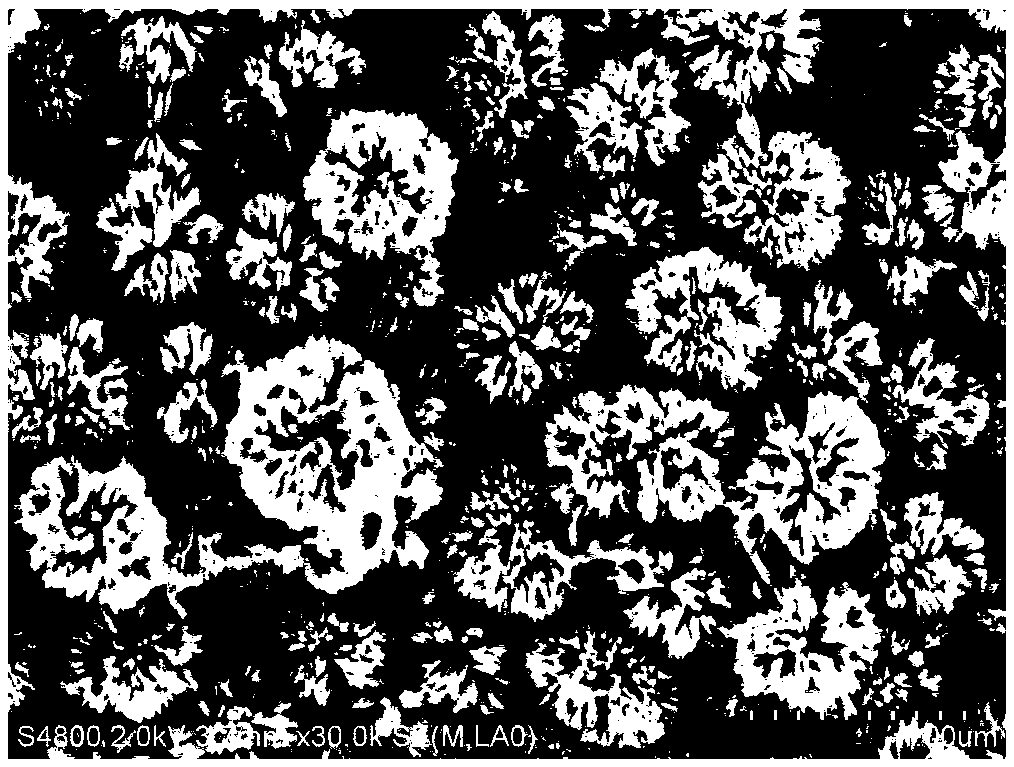

[0045] Nano-TiO 2 The microspheres are rutile TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com