Method for extracting pumpkin seed oil with supercritical CO2

A kind of pumpkin seed oil, supercritical technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problem of extracting pumpkin seed oil that has not been seen yet, achieve high yield, mature process, high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

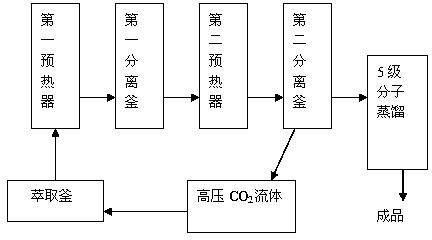

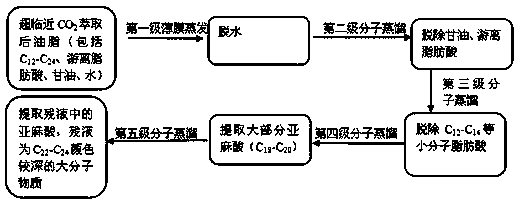

[0028] Such as figure 1 , figure 2 Shown, the supercritical CO of pumpkin seed oil provided by the present invention 2 The extraction method includes preheating, extraction, first separation, second separation, and molecular distillation process, specifically including the following steps:

[0029] (1) Select clean pumpkin seeds without shriveled and pumpkin shells, and crush them with 40-60 mesh;

[0030] (2) Put the crushed pumpkin seeds in step (1) in the extraction kettle for supercritical CO 2 Extraction, the specific extraction process is:

[0031] First, turn on the power first, preheat the extraction kettle to 40~45°C, then place the material in step (1) in the extraction kettle, and adjust the high-pressure CO into the extraction kettle. 2 Fluid pressure to 26~30MPa, stable for 2 hours;

[0032] Second, high pressure CO 2 The fluid carries the dissolved substances in the extraction tank through the first preheater and enters the first separation tank. The tempe...

Embodiment 2

[0047] The procedure for producing yellow pumpkin seed oil in this embodiment is the same as that in Example 1, except that the clean pumpkin seed oil raw material is adjusted to 0.85 kg, and crushed to 40 meshes.

[0048] During the extraction process, the temperature in the extraction kettle was preheated to 45°C, and the high-pressure CO in the extraction kettle 2 The fluid pressure is 28MPa, stable for 2 hours; the high-pressure CO with the extract in the first separation tank 2 The fluid pressure is 9MPa, the temperature of the first preheater is 40°C; the high-pressure CO with the extract in the second separation tank 2 The fluid pressure is 6MPa, and the temperature of the second preheater is 40°C.

[0049] Supercritical CO 2 After extraction, the finished product of pumpkin seed oil is obtained after further 5-stage molecular distillation.

[0050] This embodiment finally obtains 0.36Kg of pumpkin seed oil finished product, and the extraction rate is 45%. The extrac...

Embodiment 3

[0052] The procedure for producing yellow pumpkin seed oil in this embodiment is the same as that in Example 1, except that the clean pumpkin seed oil raw material is adjusted to 0.85 kg and crushed at 60 mesh.

[0053] During the extraction process, the temperature in the extraction kettle was preheated to 45°C, and the high-pressure CO in the extraction kettle 2 The fluid pressure is 30MPa, stable for 2 hours; the high-pressure CO with the extract in the first separation tank 2 The fluid pressure is 9MPa, the temperature of the first preheater is 45°C; the high-pressure CO 2 The fluid pressure is 6MPa, and the temperature of the second preheater is 40°C.

[0054] Supercritical CO 2 After extraction, the finished product of pumpkin seed oil is obtained after further 5-stage molecular distillation.

[0055] This embodiment finally obtains 0.36Kg of pumpkin seed oil finished product, and the extraction rate is 45%. The extracted pumpkin seed oil is rose red in color and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com