Multi-stage spray quenching process for achieving low residual stress of age hardening aluminum alloy

A technology of aging hardening and aluminum alloy, which is applied in the field of heat treatment of aluminum alloy and non-ferrous metal materials, and achieves the effect of simple process method and low hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

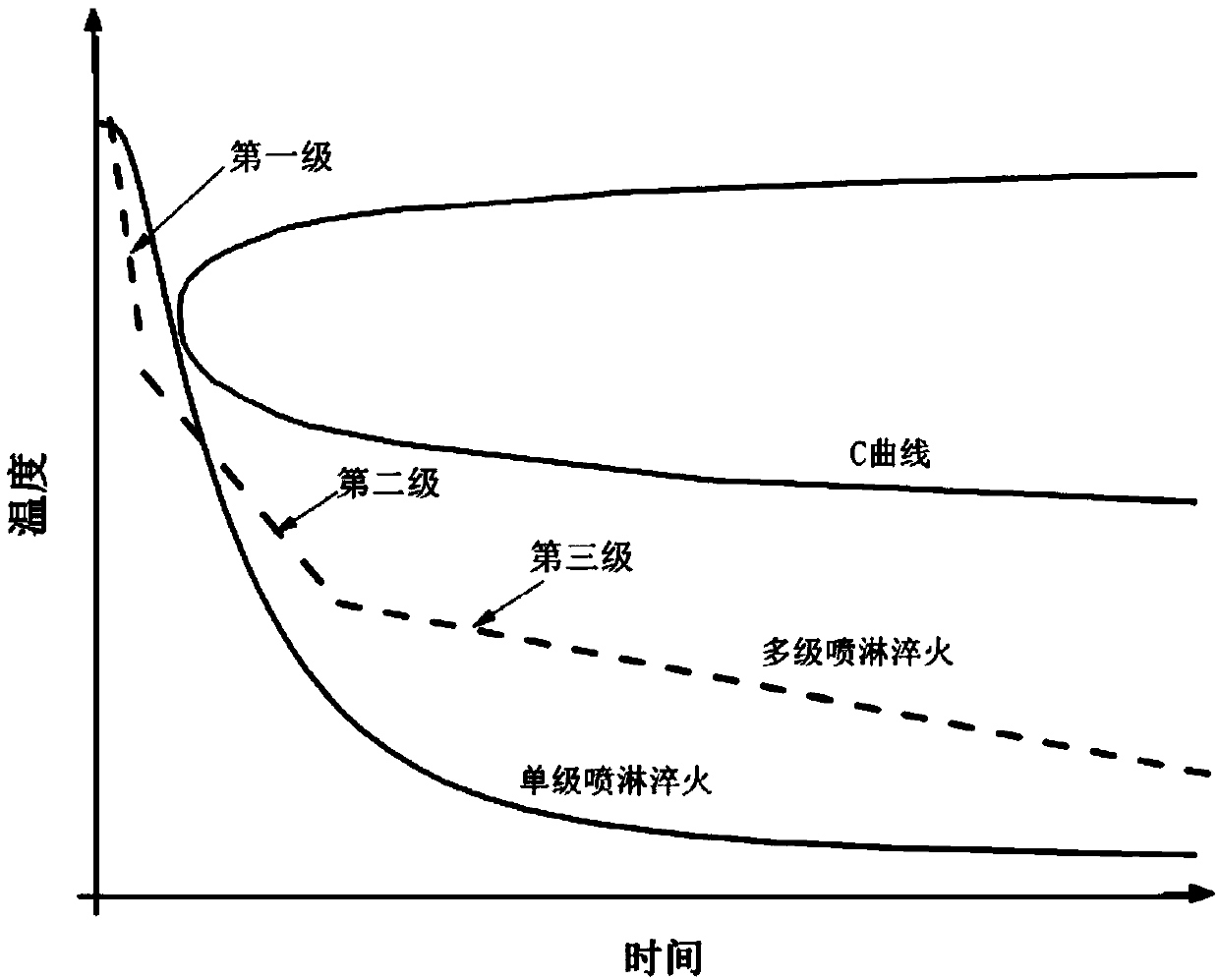

Embodiment 1

[0037]The size of the 7050 aluminum alloy thick plate is 80mm×500mm×1500mm. After solution treatment at 470°C×4 hours, it is subjected to multi-stage spray quenching, and enters the first-stage spray quenching area at a uniform speed of 240mm / s. The pressure leaving the nozzle is 300kPa, and the flow density of the spray water on the aluminum alloy plate is 100Lm -2 s -1 , after 5s, enter the second-stage spray quenching area, the pressure of the water leaving the nozzle in this area is 10kPa, and the flow density of the spray water on the aluminum alloy thick plate is 25Lm -2 s -1 , After 5s, enter the third-level air-cooling area, stop spraying water, and let it stand to room temperature. The average value of residual compressive stress on the surface obtained from the test is 144.6MPa. After the sample is subjected to T74 aging treatment, the average Vickers hardness of the core is 164.

Embodiment 2

[0041] The size of the 7050 aluminum alloy thick plate is 120mm×500mm×1500mm. After solution treatment at 470°C×4 hours, it is subjected to multi-stage spray quenching, and enters the first-stage spray quenching area at a uniform speed of 150mm / s. The pressure leaving the nozzle is 400kPa, and the flow density of the spray water on the aluminum alloy plate is 125Lm -2 s -1 , after 8s, enter the second-stage spray quenching area, the pressure of the water leaving the nozzle in this area is 20kPa, and the flow density of the spray water on the aluminum alloy thick plate is 35Lm -2 s -1 After 8 seconds, enter the third-level air-cooling area, stop spraying water, and let it stand to room temperature. The average value of the surface residual stress obtained from the test is 189.5MPa. After the sample has undergone T74 aging treatment, the average Vickers hardness of the core is 162.

Embodiment 3

[0045] The size of the 7050 aluminum alloy thick plate is 150mm×500mm×1500mm. After solution treatment at 470°C×4 hours, it is subjected to multi-stage spray quenching, and enters the first-stage spray quenching area at a uniform speed of 120mm / s. The pressure leaving the nozzle is 500kPa, and the flow density of the spray water on the aluminum alloy plate is 150Lm -2 s -1 , after 10s, enter the second-stage spray quenching area, the pressure of the water leaving the nozzle in this area is 25kPa, and the flow density of the spray water on the aluminum alloy thick plate is 60Lm -2 s -1 After 10s, enter the third-level air-cooling area, stop spraying water, and let it stand to room temperature. The average value of surface residual stress obtained from the test is 222.2MPa. After the sample has undergone T74 aging treatment, the average Vickers hardness of the core is 162.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com