Basement double-layer overlapping prefabricated outer wall

A basement and prefabricated wall panel technology, applied in the construction field, can solve the problems of unreliable connection, cracking in the node area, heavy workload, etc., and achieve the effect of reliable connection, saving construction cost and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

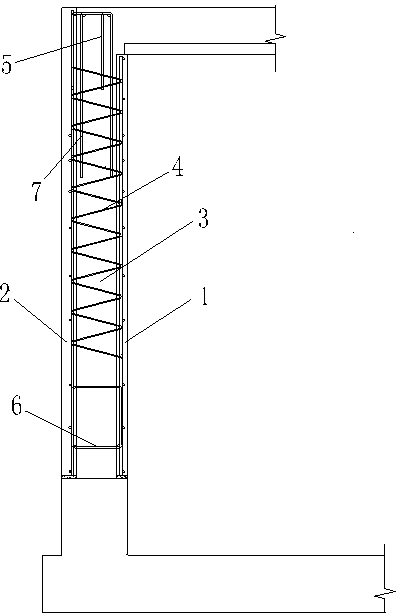

[0015] A double-layer laminated prefabricated exterior wall of a basement, comprising a double-layer laminated prefabricated panel connected between the upper and lower floors, the double-layer laminated prefabricated panel comprising a first prefabricated wall panel 1 and a second prefabricated wall panel 2, the first prefabricated wall panel Both the panel 1 and the second prefabricated wall panel 2 have vertical steel bars inside, and there is a poured concrete layer 3 between the first prefabricated wall panel 1 and the second prefabricated wall panel 2, and the first prefabricated wall panel 1 and the second prefabricated wall panel 2 The truss bars 4 are connected between them, and the truss bars 4 can also be connected to the vertical bars in the first prefabricated wall panel 1 and the second prefabricated wall panel 2, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap