Air purifier base assembly and air purifier

A technology of air purifiers and components, applied in space heating and ventilation details, household heating, lighting and heating equipment, etc., can solve the problems of occupying the design space of the whole machine, inconvenient maintenance, inconvenient movement, etc., to achieve increased The effect of air intake, convenient maintenance and disassembly, and improvement of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

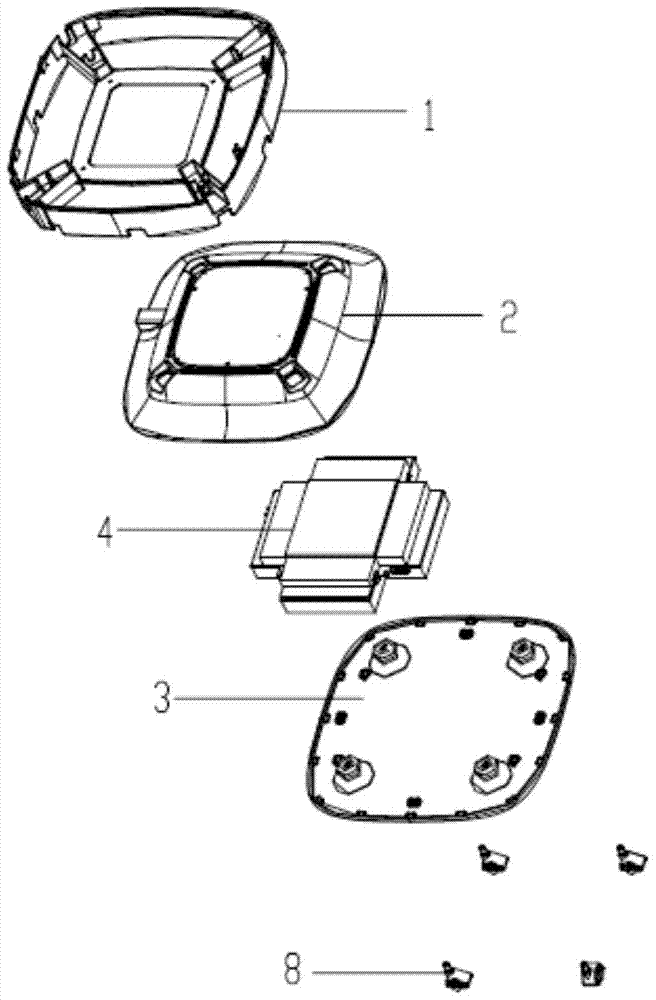

[0055] This embodiment provides an air cleaner base assembly, the structure of the air cleaner base assembly is as follows Figure 1-Figure 5 As shown, it includes a support frame 1, a chassis 2 and a bottom plate 3, the support frame 1 is fixed on the chassis 2, the chassis 2 is connected to the bottom plate 3, and a reserved space for fixing and installing electrical components 4 is formed between the chassis 2 and the bottom plate 3 5. Install the electrical component 4 in the reserved space 5. When the electrical component 4 needs to be inspected, repaired and disassembled, it is only necessary to remove the base assembly, and then disassemble the chassis 2 and the bottom plate 3, instead of disassembling the air purifier as a whole Completely disassembled for inspection and repair.

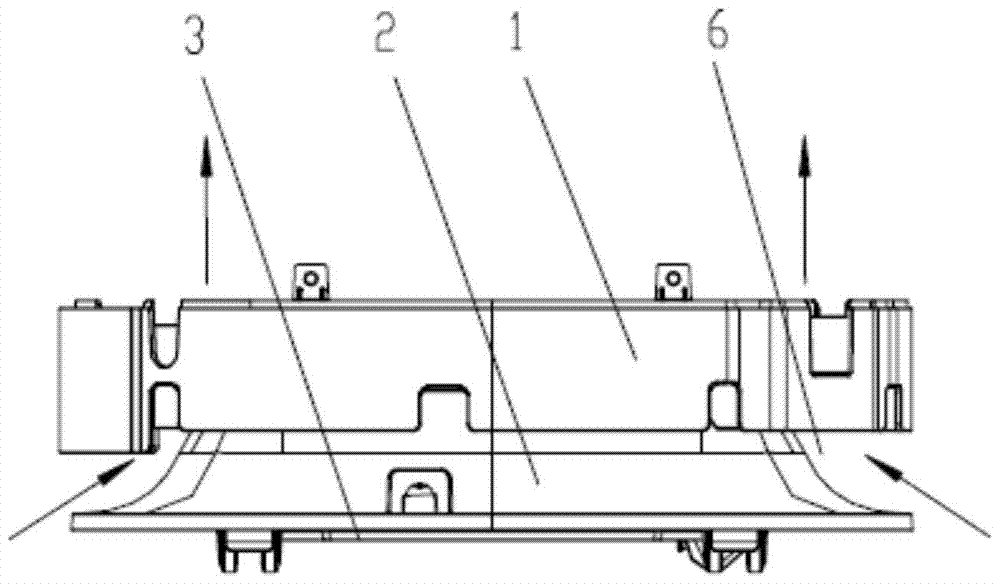

[0056] like Image 6 and Figure 7 As shown, the chassis 2 is an inverted disc structure, and the chassis 2 includes a top surface 21 and an arc-shaped side peripheral surface 22 connected...

Embodiment 2

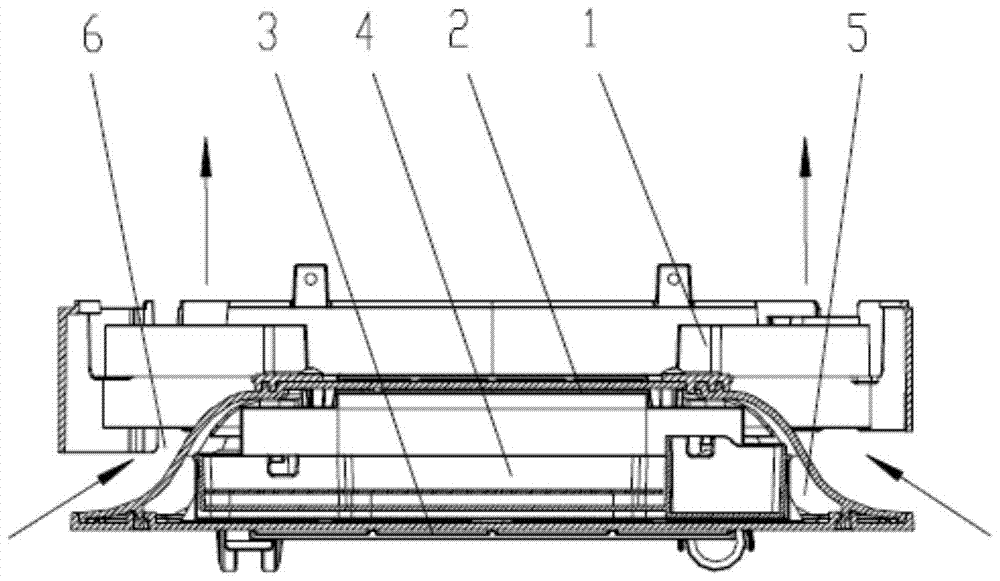

[0067] like Figure 10-Figure 15 As shown, the air cleaner base assembly provided in this embodiment is basically the same in structure as the air cleaner base assembly described in Embodiment 1. It includes a support frame 1', a chassis 2' and a bottom plate 3', the support frame 1' is fixed on the chassis 2', the chassis 2' is connected to the bottom plate 3', and the space between the chassis 2' and the bottom plate 3' is used to fix and install electrical appliances. Reserved space 5' for element 4'.

[0068] The difference is that: the top surface 21' of the chassis 2' and the bottom plate 3' are provided with a grid 7, and the grids 7 distributed on the two are arranged in parallel to each other, which not only facilitates the outside air to enter the base assembly through the grid, but also Increase the air intake, and help to dissipate heat for electrical components, the cooling effect is good, effectively prolonging the service life of electrical components.

Embodiment 3

[0070] This embodiment provides an air cleaner, which includes an air cleaner body, and the air cleaner body is fixedly installed on the base assembly of the air cleaner as described in Embodiment 1 or Embodiment 2. The air cleaner has all the above-mentioned functions of the base assembly of the air cleaner as described in Embodiment 1 or Embodiment 2.

[0071] The structure and connection form of the support frame and chassis in the present invention are not limited to the above-mentioned situation, and other structures and connection forms can also be designed, as long as the requirements of rational use of space and convenient disassembly and maintenance of electrical components are met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com