Double control and double isolation high and low temperature impact test system with heat exchange energy saving compensation

A technology for heat exchange, energy saving, and impact testing. It is applied in impact testing, testing of machines/structural components, and measuring devices. It can solve problems such as unavoidable, energy waste, and battery pollution, and achieve pollution prevention, increased working capacity, and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

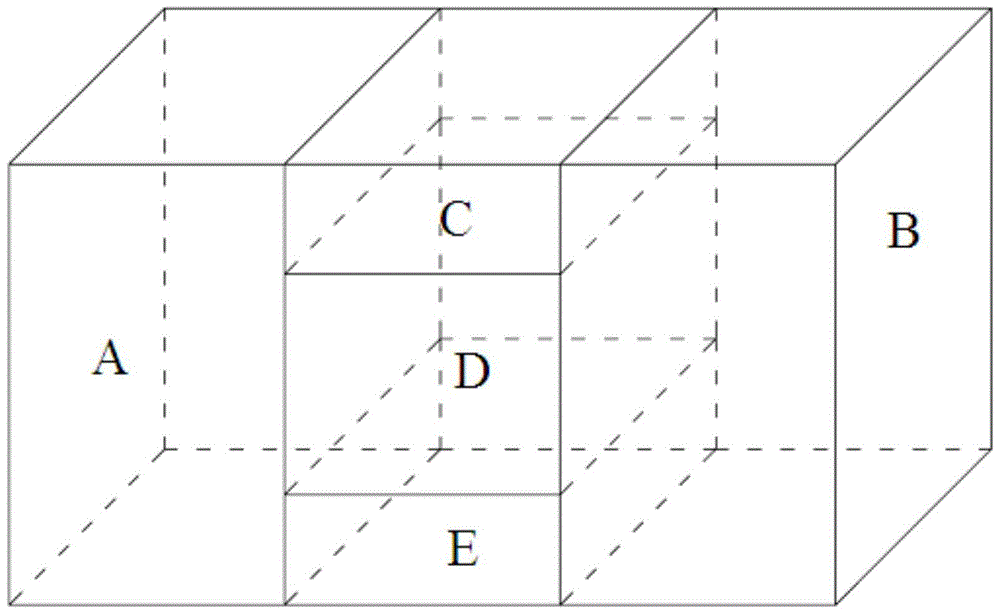

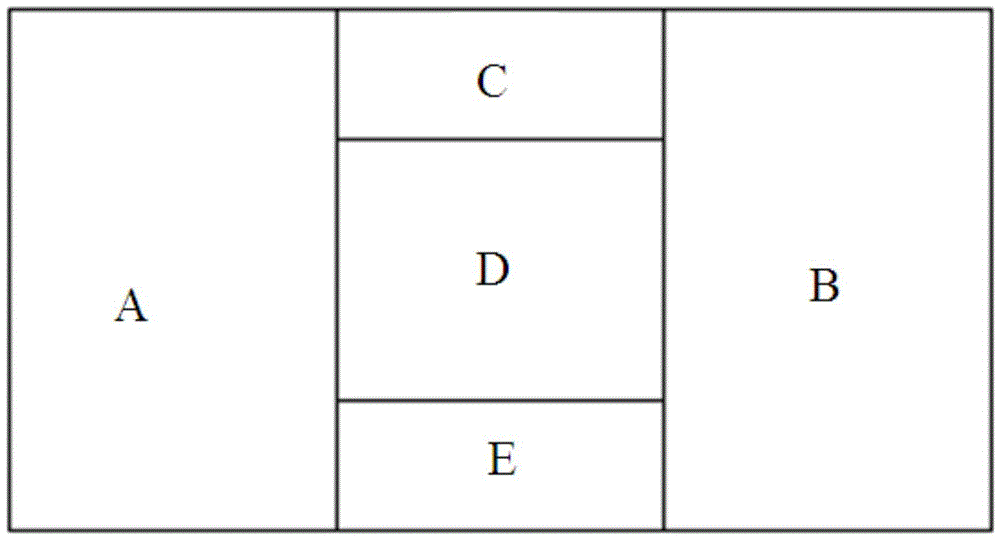

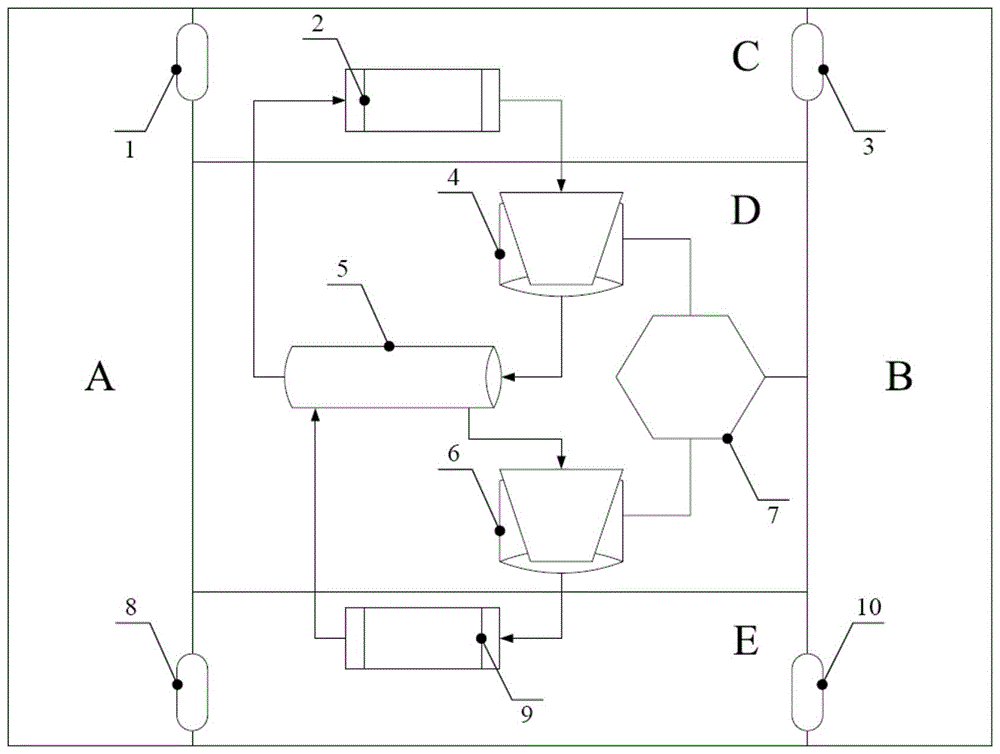

[0030] see Figure 1 ~ Figure 3 , a dual-control dual-isolation high-low temperature impact test system with heat exchange energy-saving compensation mainly includes test chamber A, test chamber B, precooling zone C, compression control zone D, and preheating zone E.

[0031] Among them, an evaporator 2 is arranged in the precooling zone C, a first low temperature valve control 1 is set between the precooling zone C and the test box A, and a second low temperature valve control 3 is set between the precooling zone C and the test box B; A condenser 9 is installed in the hot zone E, a first high temperature valve control 8 is set between the preheating zone E and the test box A, a second high temperature valve control 10 is set between the preheating zone E and the test box B; the compression control zone D It is the core control area of the high and low temperature impact test system, which is equipped with a primary compressor 4, a secondary compressor 6, a heat exchanger 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com