Triaxial remodeling soil sample forming method and device

A molding device and molding method technology, which is applied in the field of soil mechanics, can solve the problems of not being able to control the moisture content and compactness of soil samples, and achieve the solution of uneven compactness of soil samples, overcome the difference in compaction energy, and the method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

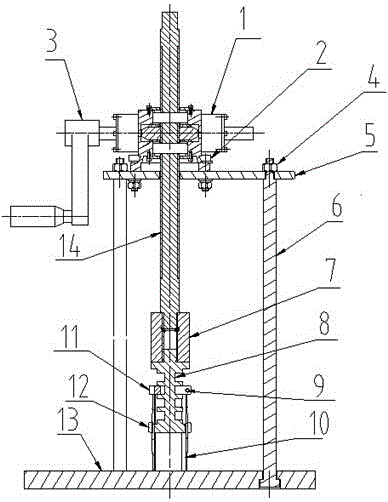

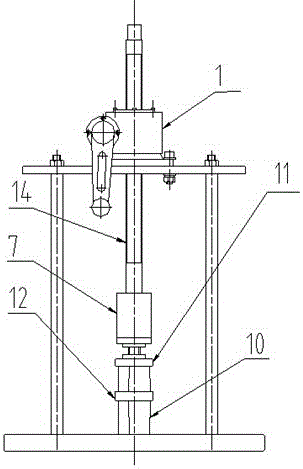

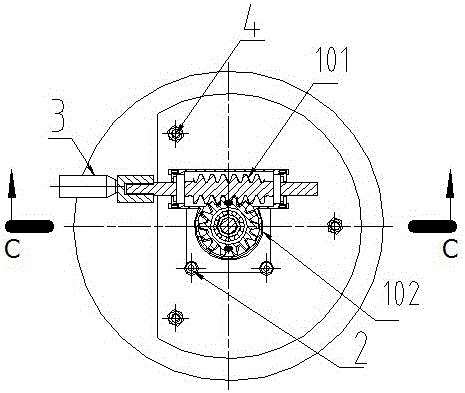

[0027] Such as Figure 1-Figure 3 As shown, the specific structure of the present invention is: the device includes a worm gear mechanism 1, a hand wheel 3, a support platform 5, a pillar 6, a connecting sleeve 7, a movable extrusion plug 8, a soil holding cylinder 10, a base 13 and a lifting rod 14 . The worm gear mechanism 1 is installed on the support platform 5 through the nut a 2, the worm 101 of the worm gear mechanism 1 is connected with the handle 3, the worm wheel 102 of the worm gear 1 is arranged in cooperation with the elevating rod 14, and the support platform 5 is connected to the pillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com