Exhaust purification device of internal combustion engine

一种排气净化装置、内燃机的技术,应用在排气装置、排气处理装置的电控、内燃活塞发动机等方向,能够解决燃料消耗量增大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

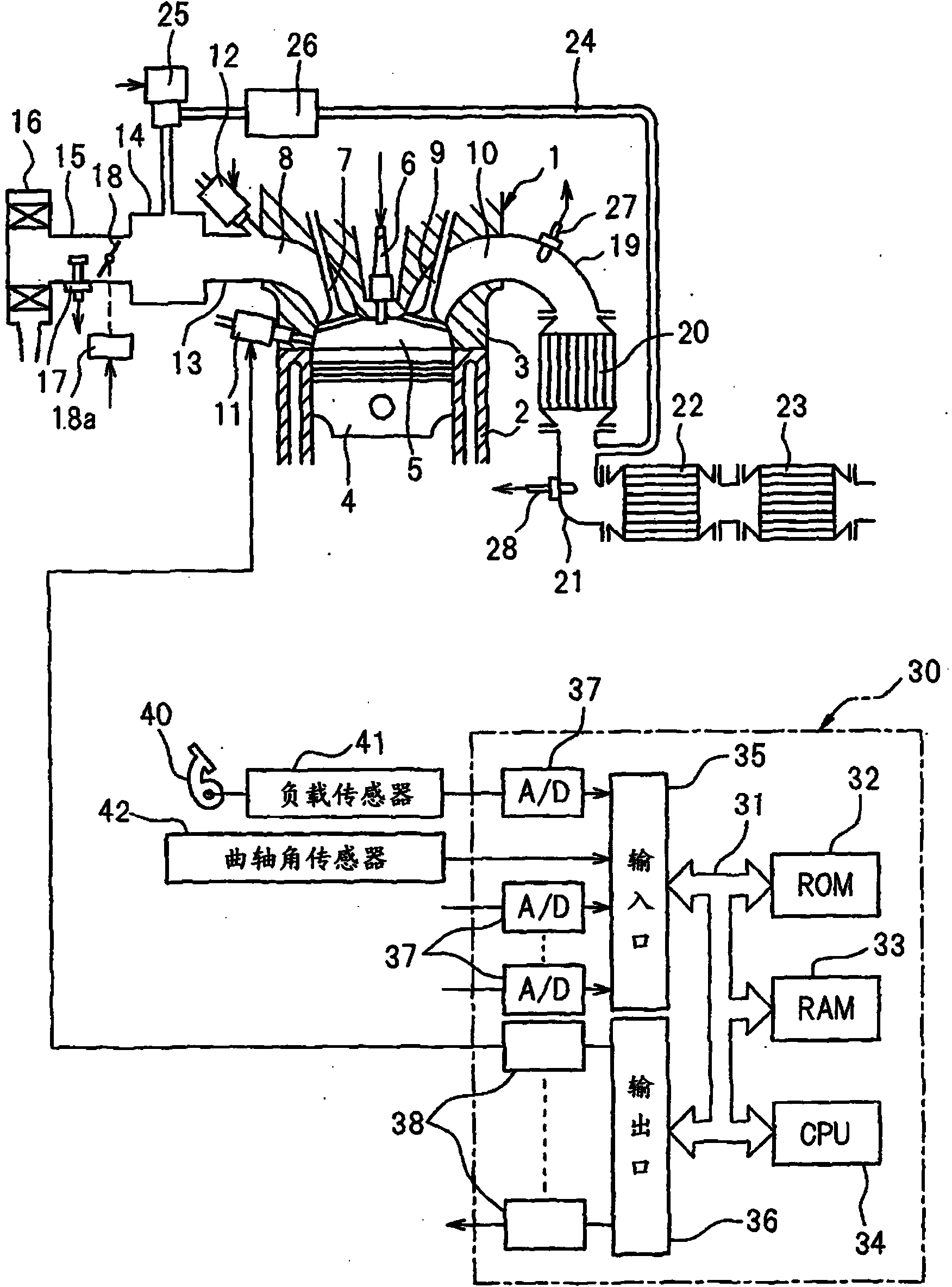

[0030] figure 1 An overall view showing a spark ignition internal combustion engine.

[0031] refer to figure 1 It can be seen that 1 represents the main body of the internal combustion engine, 2 represents the cylinder block, 3 represents the cylinder head, 4 represents the piston, 5 represents the combustion chamber, 6 represents the ignition plug, 7 represents the intake valve, 8 represents the intake port, 9 represents the exhaust valve, and 10 represents the exhaust valve. Indicates the exhaust port. Such as figure 1 As shown, each cylinder has a pair of fuel injection valves consisting of an electronically controlled fuel injection valve 11 for injecting fuel into the combustion chamber 2 and an electronically controlled fuel injection valve 12 for injecting fuel into the intake port 8. . The intake port 8 of each cylinder is connected to a surge tank 14 via an intake branch pipe 13 , and the surge tank 14 is connected to an air filter 16 via an intake duct 15 . An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com