Catalyst for methanol conversion to produce gasoline while taking into account propylene yield and preparation method thereof

A methanol conversion and catalyst technology, which is used in physical/chemical process catalysts, molecular sieve catalysts, and bulk chemical production to improve the ability to resist market risks, reduce molecular diffusion resistance, and facilitate olefin selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

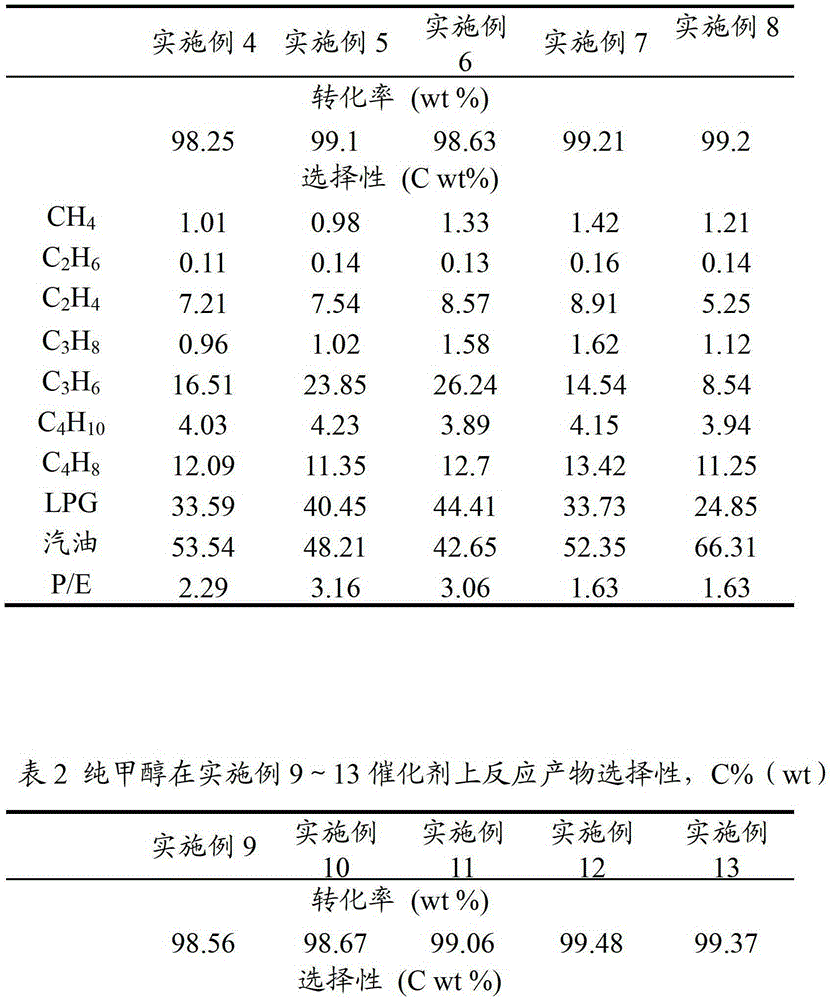

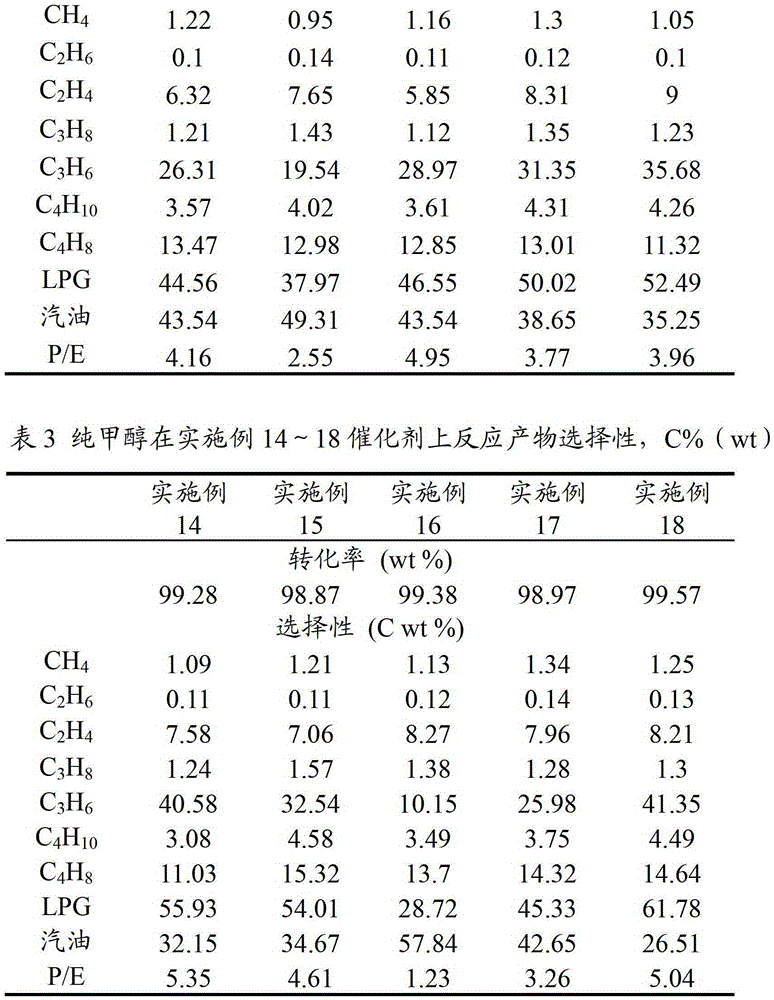

Examples

preparation example Construction

[0052] Specifically, the preparation method of the modified binder comprises:

[0053] Metal modification treatment: Mix and stir the binder and 2mol / L metal salt solution for 4 hours in a water bath at 60°C, and then let it stand at room temperature for 4-6 hours to obtain modified binder I; among them, the metal salt solution The quality of the metal salt is calculated based on the quality of the corresponding metal oxide of the metal, and the metal oxide is selected from at least one of Zn, W, B, P, Zr, Mg and Mn oxides, and the metal oxide is The mass is 0.5%-15% of the mass of the binder;

[0054] Static hydrothermal crystallization treatment: Put the binder into the crystallization kettle, statically crystallize at 100°C for 2-8 hours, and then stand at room temperature for 4-6 hours to obtain modified binder II;

[0055] The modified binder I and the modified binder II are mixed at a mass ratio of 0.1-10:1, and the modified binder is obtained after uniform stirring.

...

Embodiment 1

[0061] Preparation of modified silica sol: first mix 20g of silica sol with 5mL 2mol / L zinc nitrate solution in a 60°C water bath and stir for 4h, then let it stand at room temperature for 6h to obtain modified silica sol Ⅰ; then mix 20g of silica sol Put it into a crystallization kettle, statically crystallize at 100°C for 6 hours, and then stand at room temperature for 4 hours to obtain modified silica sol II; finally, modify silica sol I and modified silica sol II at a mass ratio of 1:1 The ratio is mixed, and the modified silica sol is obtained after stirring evenly.

Embodiment 2

[0063] Preparation of modified aluminum sol: first mix 10g of water glass with 8mL of 2mol / L magnesium nitrate solution in a 60°C water bath and stir for 4h, then leave it at room temperature for 4h to obtain modified aluminum sol I; then mix 30g of water glass with Put it into a crystallization kettle, statically crystallize at 100°C for 4 hours, and then stand at room temperature for 4 hours to obtain modified aluminum sol II; finally, modify aluminum sol I and modified aluminum sol II in a mass ratio of 1:3 The ratio is mixed, and the modified aluminum sol is obtained after stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com