Method for preparing polycarboxylic acid by electrocatalytic oxidation of aldehydes and alcohols

An electrocatalytic oxidation, polycarboxylic acid technology, applied in electrodes, electrolysis components, electrolysis process and other directions, can solve the problems of large oxidant, low selectivity of glucaric acid, high cost, etc., and achieve low preparation cost, excellent stability, The effect of multiple active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

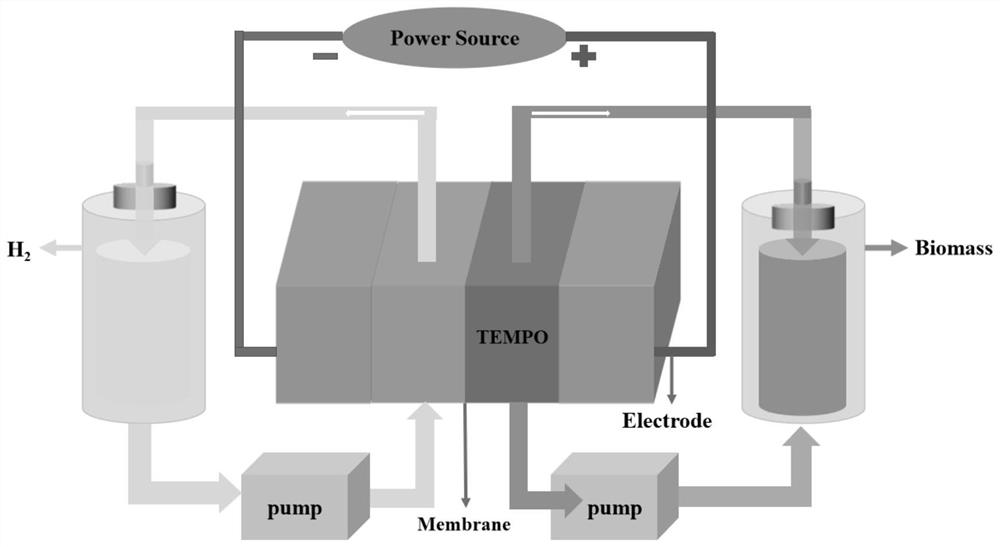

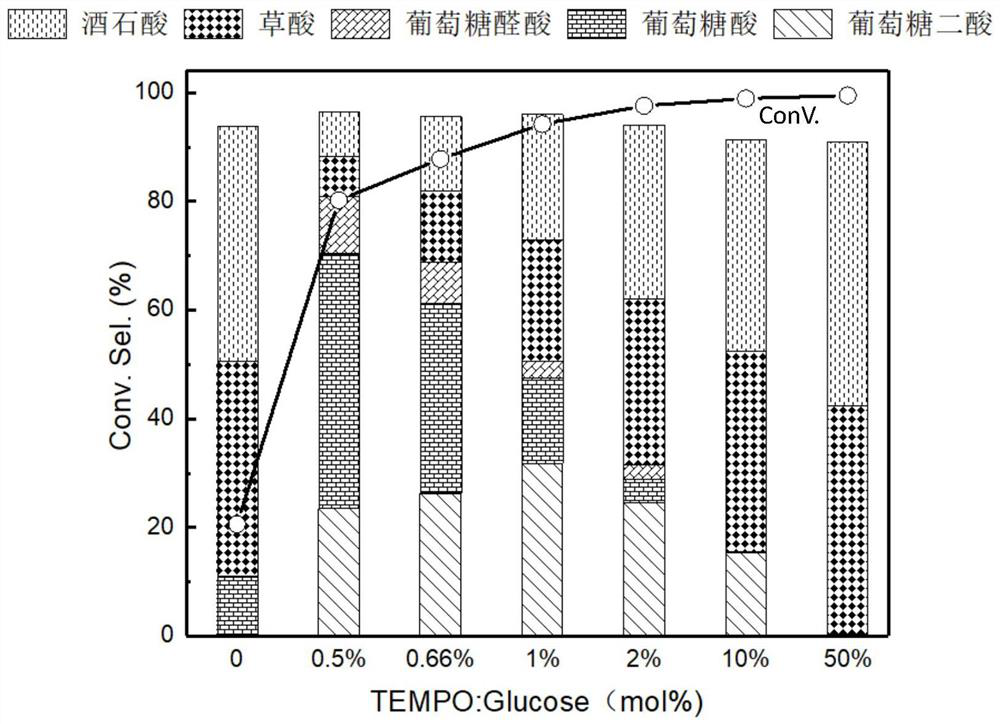

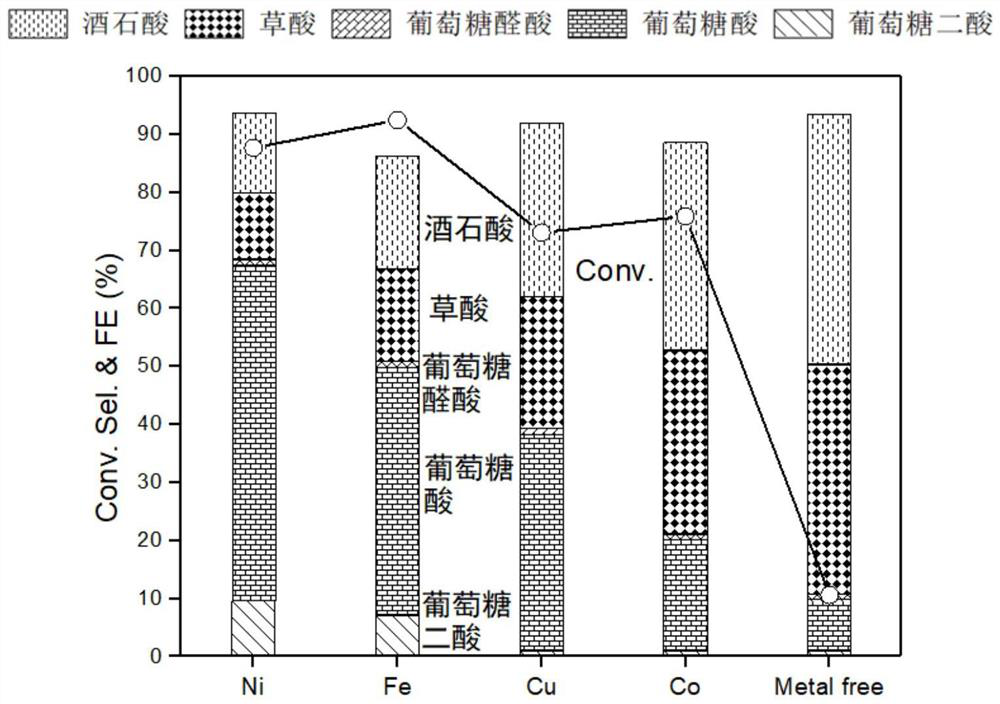

[0033] Example 1 A method for constructing an electrocatalytic system that couples Fe LDH nanosheets of polyacids prepared by oxidation of biomass and nitroxide free radical compounds.

[0034] Pretreatment of carbon felt: Sonicate commercial carbon felt in absolute ethanol and distilled water for 4 minutes, wash to remove surface impurities, then use carbon felt as working electrode, platinum sheet as counter electrode, mercury / mercury oxide electrode as reference electrode, 1M NaOH solution is the electrolyte, and it is oxidized by chronopotentiometry. After the treatment, the carbon felt is ultrasonically washed with a large amount of distilled water for 30 minutes to remove residual NaOH. In the chronopotentiometry, the potential is 1.9V (vs. RHE), and the processing time is 10min.

[0035]Dissolve 0.2 g of urea and 0.1 g of ferric nitrate in deionized water, add absolute ethanol, stir, and ultrasonically mix for 10 min to obtain a yellow clear solution. Transfer the solu...

Embodiment 2

[0039] Example 2 A method for constructing an electrocatalytic system coupled with Ni LDH nanosheets and nitroxide radical compounds for the preparation of polybasic acids by oxidation of biomass

[0040] Dissolve 1 g of urea and 1 g of nickel nitrate in deionized water, add absolute ethanol, stir, and ultrasonically mix for 10 minutes to obtain a green clear solution. Transfer the solution to the PTFE lining, put a piece of carbon felt, seal it in a hydrothermal autoclave, and keep it warm at 160°C for 16h. After cooling down, wash with ethanol and distilled water for several times in sequence to obtain the precursor. After drying the precursor in an oven at 60°C for 1 hour, the precursor is calcined in a muffle furnace, and the temperature is programmed at a rate of 5°C / min in an air atmosphere to 400°C and keep it for 4h to get the final NiO-CF catalyst. Before the catalyst is officially used, it needs to be activated in the reaction system.

[0041] The NiO-CF prepared a...

Embodiment 3

[0043] Example 3 A method for constructing an electrocatalytic system coupled with Co LDH nanosheets and nitroxide free radical compounds for the preparation of polybasic acids by oxidation of biomass

[0044] Dissolve 1.5 g of urea and 1 g of cobalt nitrate in deionized water, add absolute ethanol, stir, and ultrasonically mix for 10 minutes to obtain a red clear solution. Transfer the solution to the PTFE lining, put a piece of carbon felt, seal it in a hydrothermal autoclave, and keep it warm at 170°C for 20h. After cooling down, wash with ethanol and distilled water for several times in sequence to obtain the precursor. After drying the precursor in an oven at 60°C for 1 hour, the precursor is calcined in a muffle furnace, and the temperature is programmed at a rate of 5°C / min in an air atmosphere to 450°C and keep for 4h to get the final Co 3 o 4 - CF catalyst. Before the catalyst is officially used, it needs to be activated in the reaction system.

[0045] The above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com