Pulverizer

A pulverizer and rack technology, applied in the field of shrub pulverizers, can solve problems such as difficulties, material blocking and discharging, and no screen mesh installation, and achieve the effects of low production cost, low equipment failure, and breakthrough in pulverization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

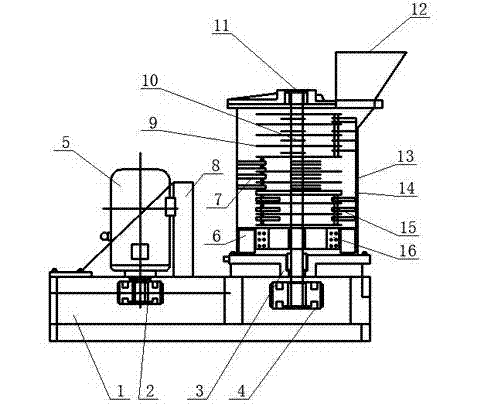

[0014] Start the pulverizer with a step-down starter cabinet. After the pulverizer is fully started, send the wet material into the pulverizer inlet 12 through the conveyor belt or the screw machine (both refer to figure 1 ), at this time, due to the high-speed operation of the pulverizer, the cutter head 9 and the flying blade 7 impeller and blade 16 start to work and rotate under the drive of the main shaft 10. Except for the feed inlet, other places are close to sealing, so the wind can only be sucked into the machine cavity by the high-speed rotating blades from the feed inlet, and at the same time, the material sent into the feed inlet is sucked into the machine cavity; the material enters the pulverizer Finally, it enters the machine cavity from top to bottom, and is broken and torn by the high-speed rotating flying knife 7 and steel casting 14. As the material falls, the material is gradually crushed into finer and finer powder, and finally passes through the Material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com