A kind of polyurethane containing dopo group and preparation method thereof

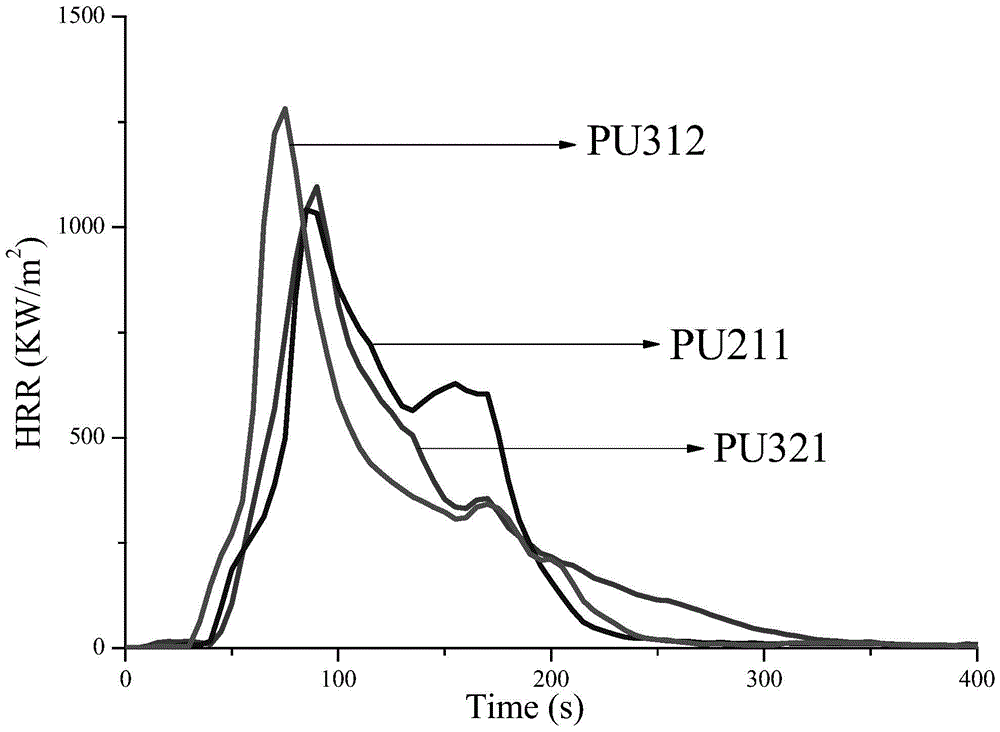

A polyurethane and group technology, applied in the field of flame retardant materials, can solve the problems of severe flames, droplet phenomenon, fire hazards, etc., and achieve the effects of reducing the peak heat release rate, short cycle, and reducing heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

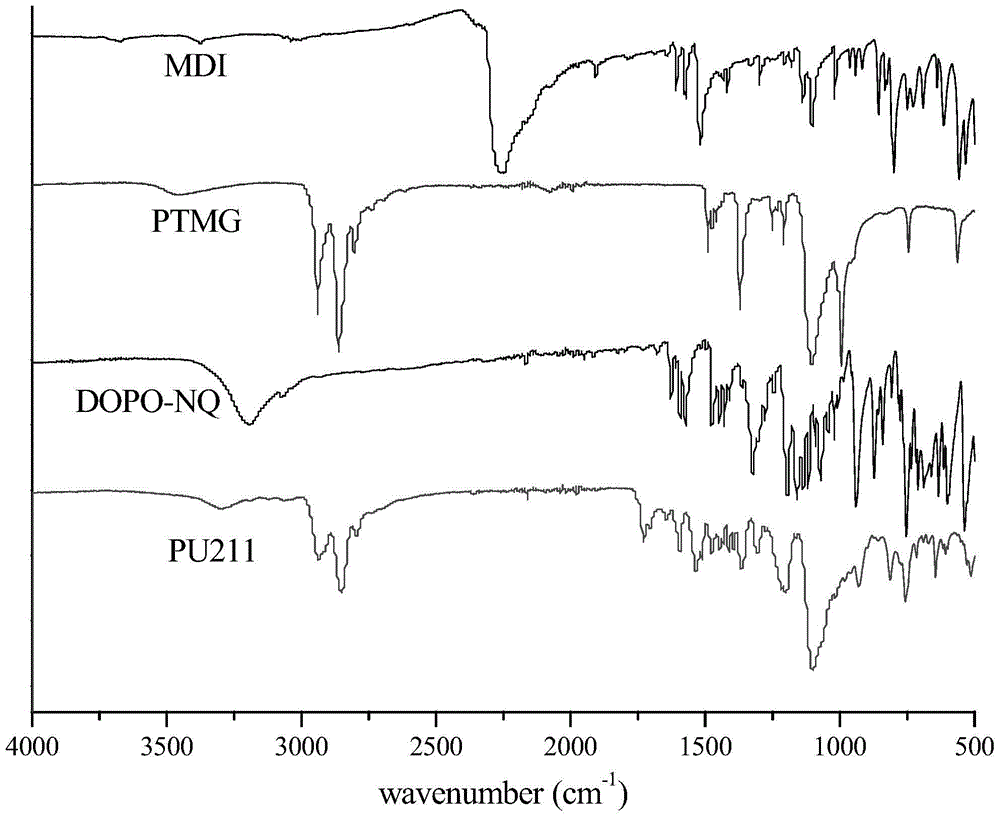

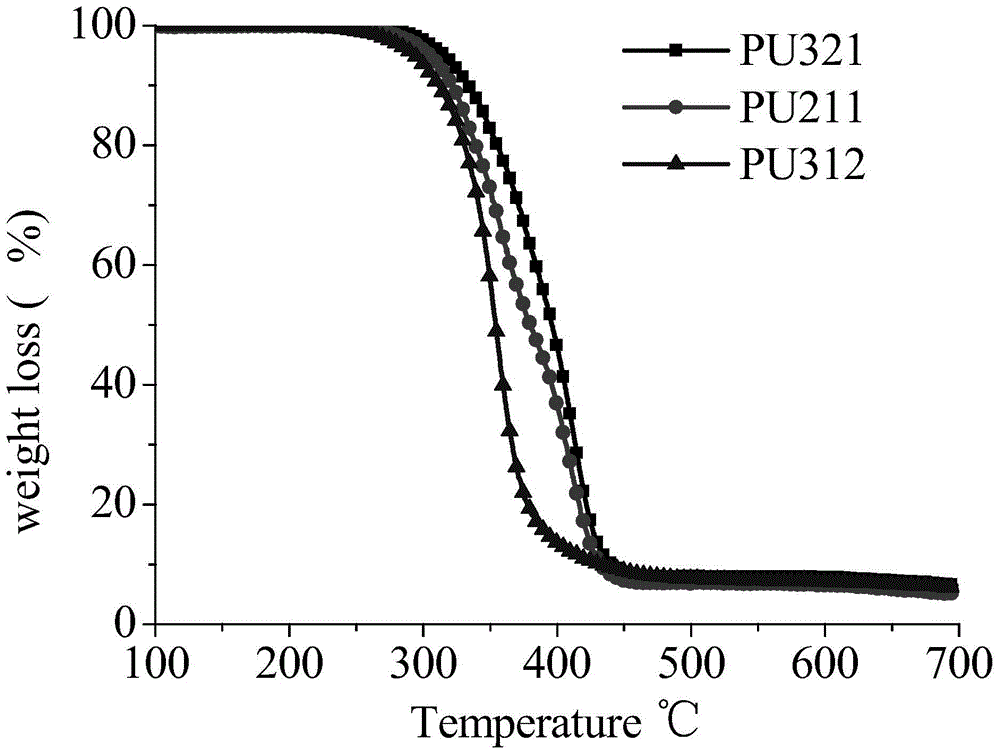

[0034] Preparation of MDI:PTMG:DOPO-NQ molar ratio of 3:2:1 DOPO group-containing polyurethane, called PU321; the number average molecular weight of PTMG is 2000; DOPO-NQ molecular formula is:

[0035] The raw materials are: 75.0g of MDI, 400.0g of PTMG, 37.4g of DOPO-NQ, and 500mL of N,N-dimethylformamide solvent;

[0036] 1) Put 400.0g of PTMG in a high-temperature vacuum oven at 120°C to remove moisture under vacuum for 3 hours;

[0037] 2) Add 75.0g of solid MDI into the reaction vessel and melt it at 50°C;

[0038] 3) Add 400.0 g of liquid PTMG obtained in step 1) into 75.0 g of liquid MDI obtained in step 2), stir under vacuum, and perform addition reaction at 80° C. for 1 hour, and release the vacuum;

[0039] 4) Add the N,N-dimethylformamide solution containing 37.4g DOPO-NQ to the product obtained in step 3), stir, and carry out the chain extension reaction at 70°C for 24 hours to obtain the polyurethane PU321 containing DOPO groups .

[0040] Above-mentioned ste...

Embodiment 2

[0044]Preparation of MDI:PTMG:DOPO-NQ molar ratio of 2:1:1 DOPO-containing polyurethane, called PU211;

[0045] The raw materials are: 50.0g of MDI, 200.0g of PTMG, 37.4g of DOPO-NQ, and 500mL of N,N-dimethylformamide solvent;

[0046] The preparation method is the same as in Example 1 to obtain DOPO-containing polyurethane PU211.

Embodiment 3

[0048] Preparation of MDI:PTMG:DOPO-NQ molar ratio of 3:1:2 DOPO-containing polyurethane, called PU321;

[0049] The raw materials are: MDI is 75.0g, PTMG is 100.0g, DOPO-NQ is 74.8g, N,N-dimethylformamide solvent is 500mL;

[0050] The preparation method is the same as in Example 1 to obtain DOPO-containing polyurethane PU312.

[0051] Table 1

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com