Oriented and flattened material composition, display device and display color adjusting method

一种材料组合物、取向材料的技术,应用在取向材料组合物领域,能够解决颜色范围窄、色域不满足客户需求、液晶显示装置厂家可操作性小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 15% butyl cellosolve and 5% polyimide resin are dissolved in 60% N-methyl-2-pyrrolidone solvent, and 20% R is the spiropyran of general formula 1 wherein nitro The quasi-compound is used as an organic additive, and the components are fully stirred until the components are uniformly mixed, thereby preparing the alignment material composition I.

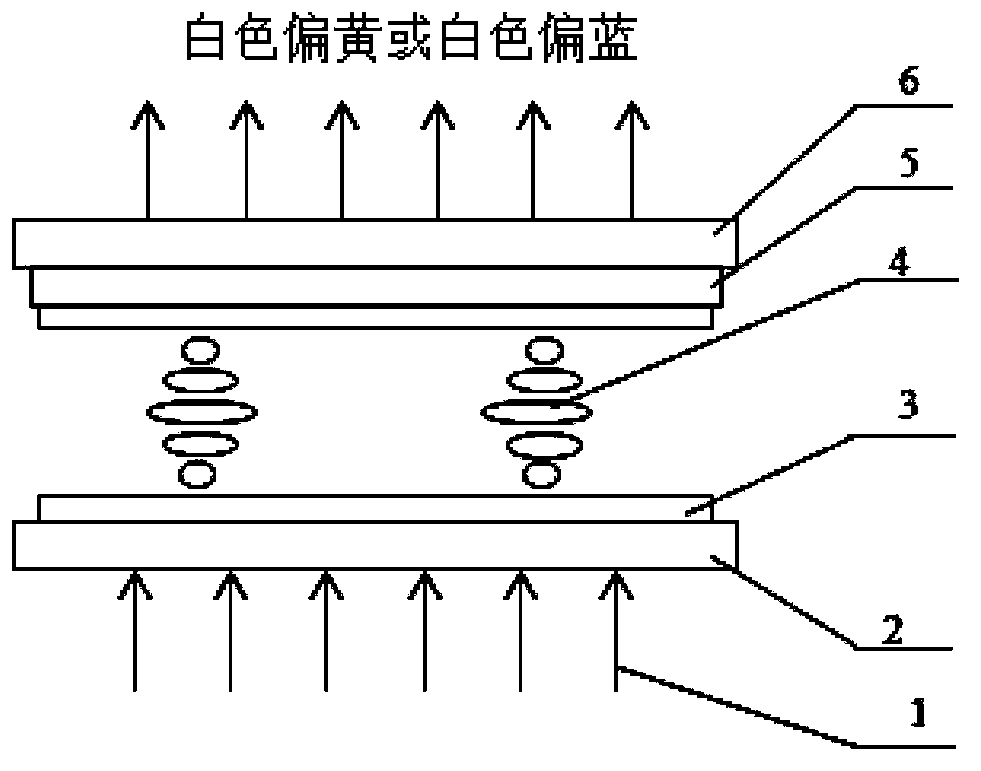

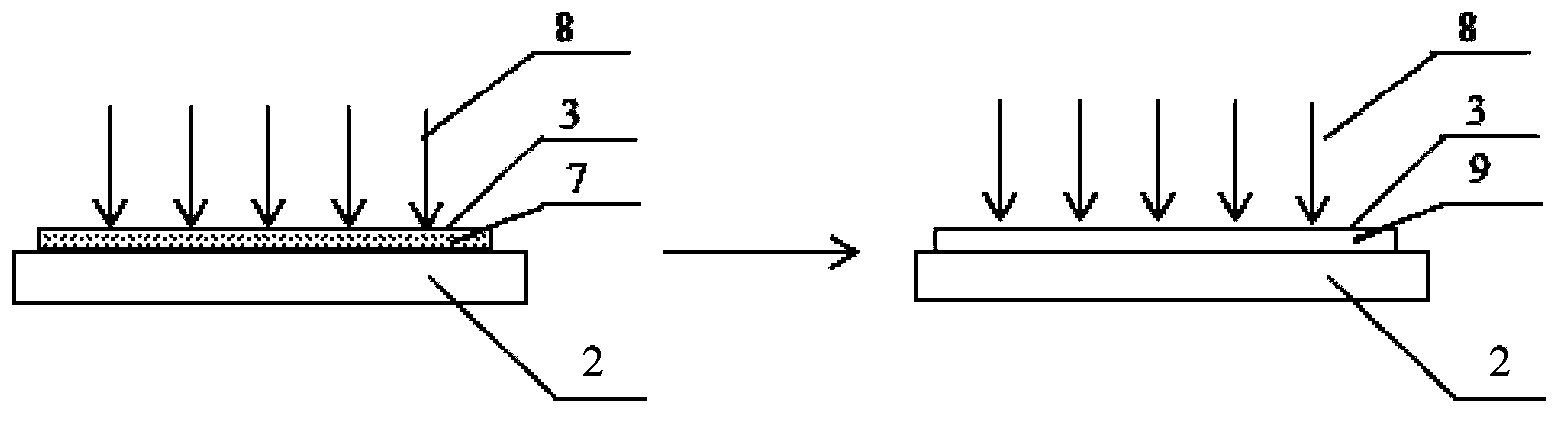

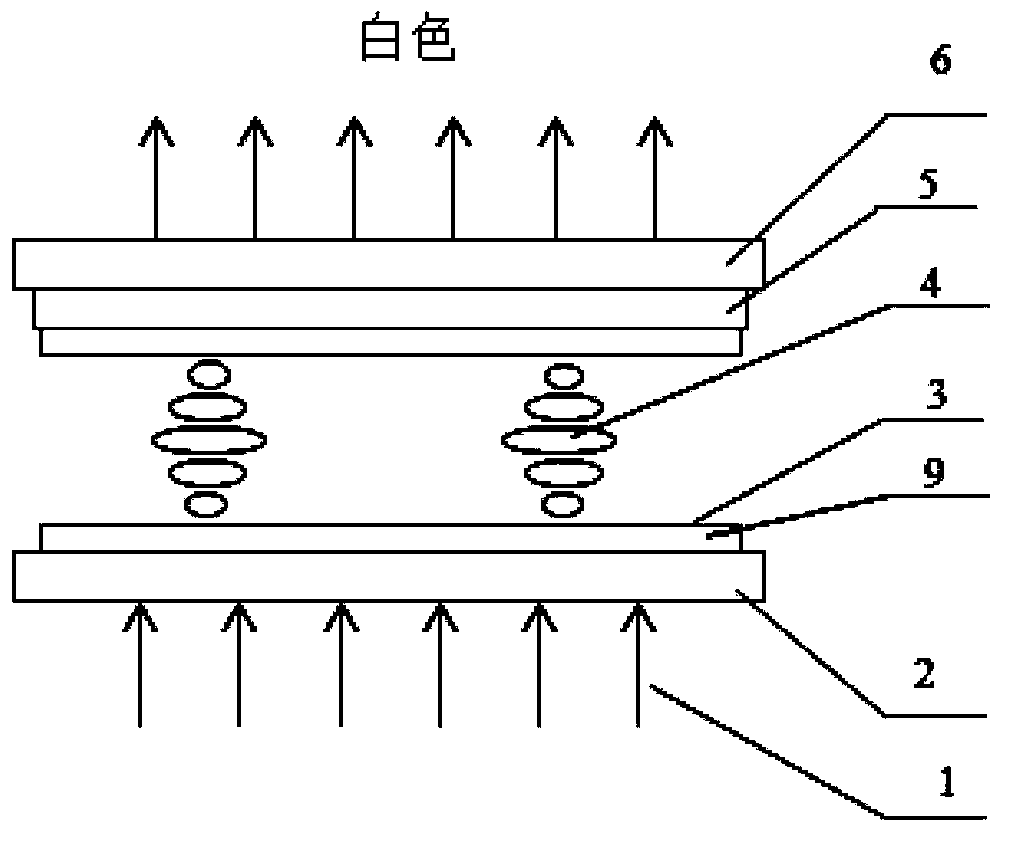

[0068] like figure 2 As shown, in order to improve the yellowish phenomenon of the display color described in Comparative Example 1, a liquid crystal display device was prepared in the same method as Comparative Example 1, except that the array substrate 2 and the color filter substrate 6 were coated with Alignment material composition 1 of organic additive 7 (R is a spiropyran compound of general formula 1 in which nitro) is sensitive to ultraviolet light forms alignment material layer 3 . Then, the alignment material layer 3 is irradiated with 365 nm ultraviolet light 8 for 60 seconds, and the alignment material layer 3 is t...

Embodiment 2

[0075] Dissolve 20% butyl cellosolve and 5% polyimide resin in 65% N-methyl-2-pyrrolidone solvent, add 10% salicylaldehyde anthranilic acid Schiff base and Cu + As an organic additive, the complex was fully stirred until the components were evenly mixed, thereby preparing the alignment material composition II.

[0076] like Figure 4 As shown, in order to improve the bluishness of the display color described in Comparative Example 2, a liquid crystal display device was prepared in the same manner as Comparative Example 2, except that the array substrate 2 and the color filter substrate 6 were coated with UV-sensitive organic additive 10 (salicylaldehyde anthranilic acid Schiff base and Cu + The alignment material composition II of the complex) to form the alignment material layer 3. The alignment material layer 3 is then irradiated with 365 nm ultraviolet light 8 for 45 seconds, and the alignment material layer 3 is transformed into a yellowish alignment layer 3 (x: 0.37, y:...

Embodiment 3

[0079] 18% butyl cellosolve and 5% polyimide resin are dissolved in 65% N-methyl-2-pyrrolidone solvent, 12% dithiophene perfluorocyclopentene is added thereto as organic additive, Thoroughly stir until all the components are uniformly mixed, thus preparing alignment material composition III.

[0080] like Figure 4 As shown, in order to improve the bluishness of the display color described in Comparative Example 2, a liquid crystal display device was prepared in the same manner as Comparative Example 2, except that the array substrate 2 and the color filter substrate 6 were coated with The alignment material composition III of the organic additive 12 (dithiophene perfluorocyclopentene) sensitive to ultraviolet light forms the alignment material layer 3 . The alignment material layer 3 is then irradiated with 365 nm ultraviolet light 8 for 90 seconds, and the alignment material layer 3 is converted into a yellowish alignment layer 3 (x: 0.36, y: 0.37). This is because the dit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com