Structure processing method for vertical isolation seam with shock insulation structure

A treatment method and isolation joint technology, applied in the direction of earthquake resistance, building components, building insulation materials, etc., can solve the problems of difficult vertical isolation joints and obstacles to relative movement of buildings, and achieve easy local materials, simple structure, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

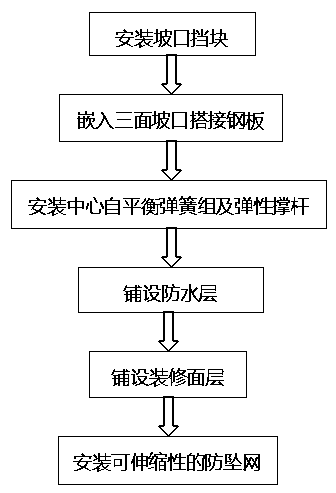

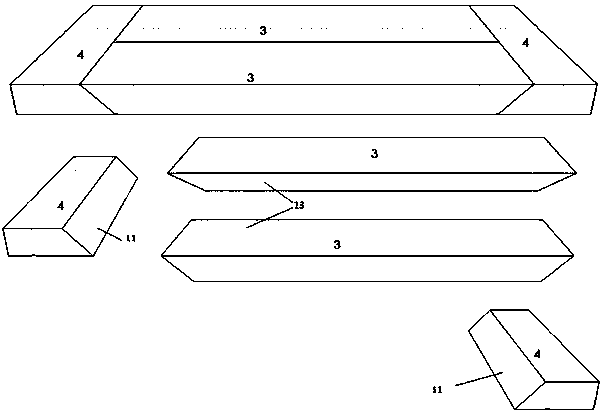

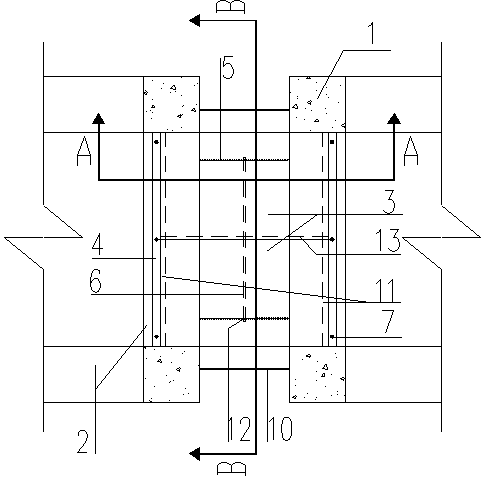

[0032] Embodiment 1: as Figure 1-15 As shown in Fig. 1, a structural treatment method for vertical isolation joints of seismic isolation structures, first install groove stops on both sides of the isolation joint, and then embed two steel plates with three-sided groove laps between the grooves of the two groove stops The steel plate layer is formed in the inverted trapezoidal groove between them, and then two self-balancing spring groups and elastic struts at the bottom center of the lapped steel plate with three-sided grooves are installed, and then the waterproof layer is laid on the steel plate layer, and then the decorative surface is laid on the waterproof layer. layer, and finally install the scalable anti-drop net;

[0033] The concrete steps of described method are as follows:

[0034] A. Install groove stoppers; on the reinforced concrete beams 2 on the left and right sides of the completed vertical separation joint, fix two groove stoppers 4 to the reinforced concr...

Embodiment 2

[0040] Embodiment 2: as Figure 1-15 As shown in Fig. 1, a structural treatment method for vertical isolation joints of seismic isolation structures, first install groove stops on both sides of the isolation joint, and then embed two steel plates with three-sided groove laps between the grooves of the two groove stops The steel plate layer is formed in the inverted trapezoidal groove between them, and then two self-balancing spring groups and elastic struts at the bottom center of the lapped steel plate with three-sided grooves are installed, and then the waterproof layer is laid on the steel plate layer, and then the decorative surface is laid on the waterproof layer. layer, and finally install the scalable anti-drop net;

[0041] The concrete steps of described method are as follows:

[0042] A. Install groove stoppers; on the reinforced concrete beams 2 on the left and right sides of the completed vertical separation joint, fix two groove stoppers 4 to the reinforced concr...

Embodiment 3

[0049] Embodiment 3: as Figure 1-15 As shown in Fig. 1, a structural treatment method for vertical isolation joints of seismic isolation structures, first install groove stops on both sides of the isolation joint, and then embed two steel plates with three-sided groove laps between the grooves of the two groove stops The steel plate layer is formed in the inverted trapezoidal groove between them, and then two self-balancing spring groups and elastic struts at the bottom center of the lapped steel plate with three-sided grooves are installed, and then the waterproof layer is laid on the steel plate layer, and then the decorative surface is laid on the waterproof layer. layer, and finally install the scalable anti-drop net;

[0050] The concrete steps of described method are as follows:

[0051] A. Install groove stoppers; on the reinforced concrete beams 2 on the left and right sides of the completed vertical separation joint, fix two groove stoppers 4 to the reinforced concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com