Wafer thickness measuring device applied to sapphire thinning device

A wafer and sapphire technology, applied in the field of wafer thickness measuring devices, can solve problems such as non-compliance, complicated measurement process, and insufficient measurement accuracy, and achieve reliable work, high measurement accuracy, and low measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below in conjunction with the drawings.

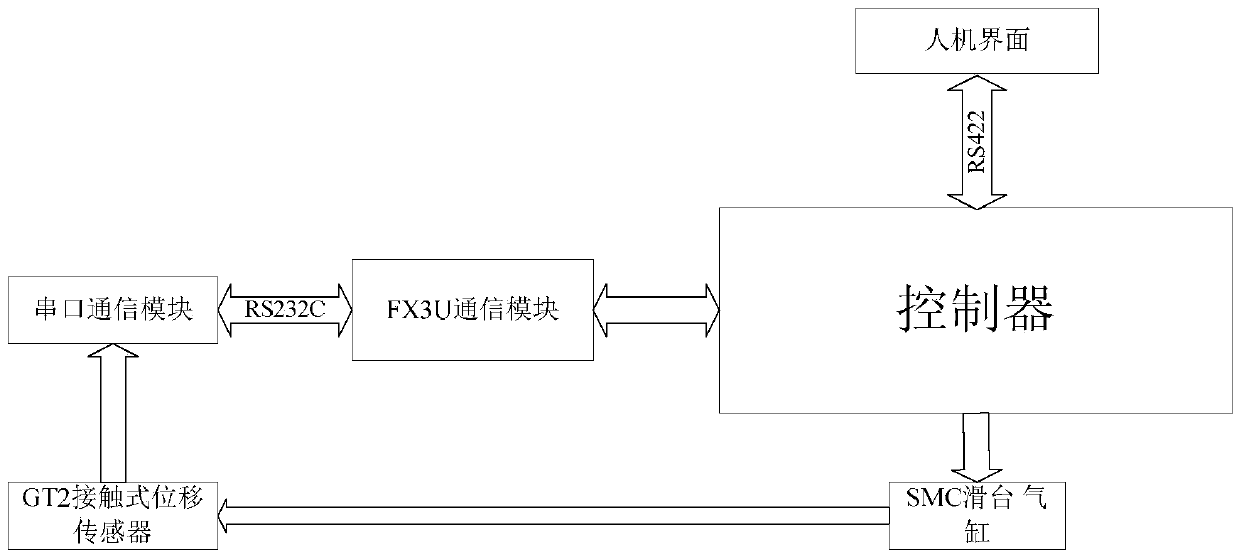

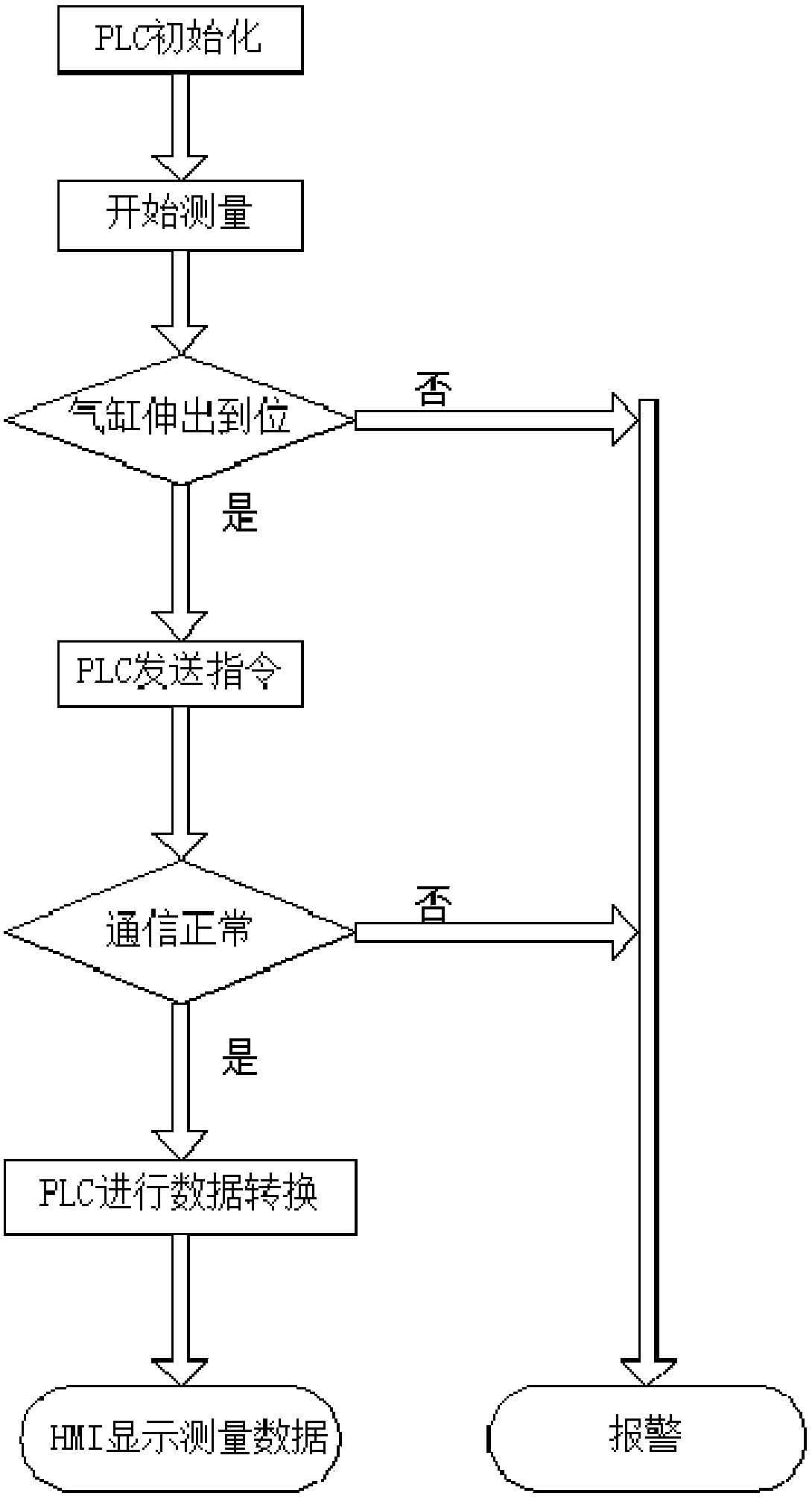

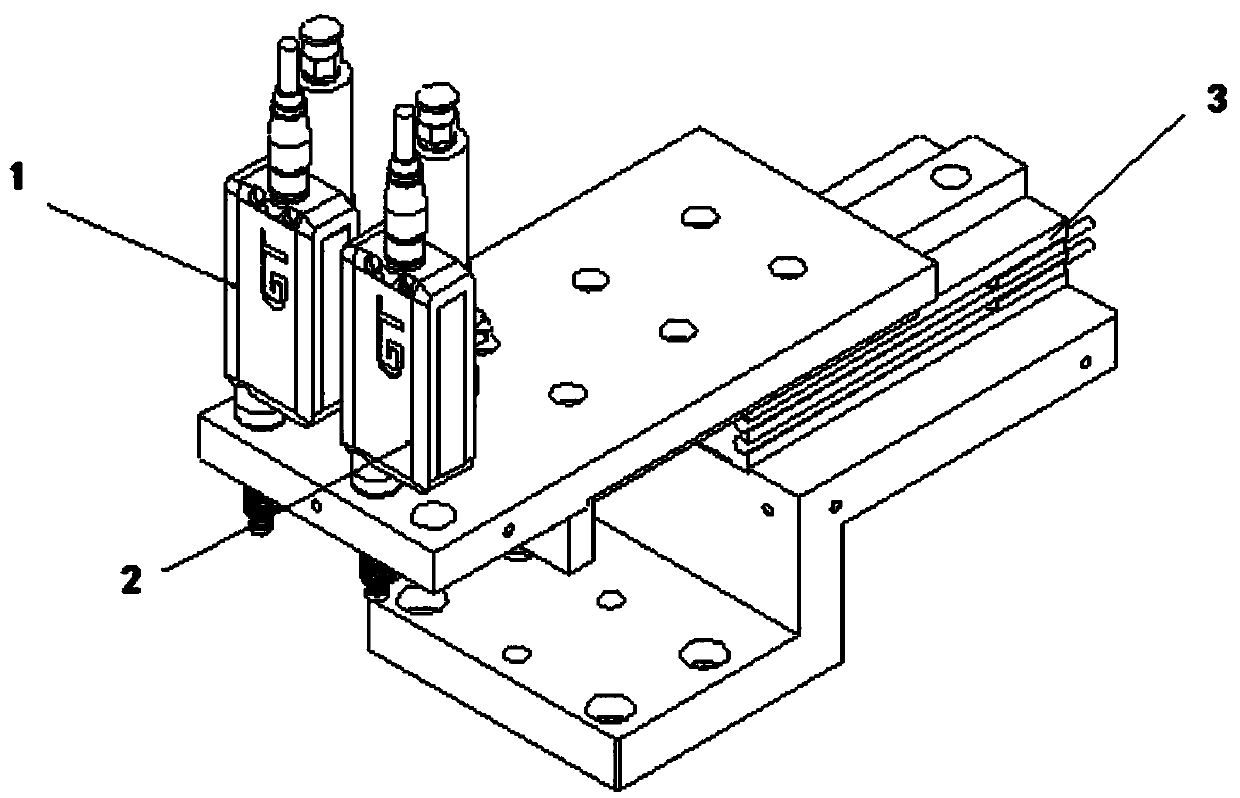

[0019] Such as Figure 1 to Figure 3 As shown, a wafer thickness measurement device applied to sapphire thinning equipment of the present invention includes a cylinder actuator, a controller (PLC) connected to the cylinder actuator, and performs between the cylinder actuator and the controller. The communication module for data transmission and the human-computer interaction interface. The cylinder actuator includes an SMC sliding table cylinder 3, a contact displacement sensor fixed to the SMC sliding table cylinder 3 through a fixed block, and the contact displacement sensor is provided with a main probe 1 and an extension Probe 2, the contact type displacement sensor transmits the measured data information to the controller through the communication module, and the controller compares the received data information with the target data and judges whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com