On-line detector for corn bulk density and its detection method

A detector, corn technology, applied in specific gravity measurement, instruments, measurement devices, etc., can solve problems such as unfavorable continuous measurement and elimination of errors, inability to achieve automatic measurement, inability to continuous measurement, etc., and achieve accurate and reliable detection results. The degree of automation And the effect of high work efficiency and no manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

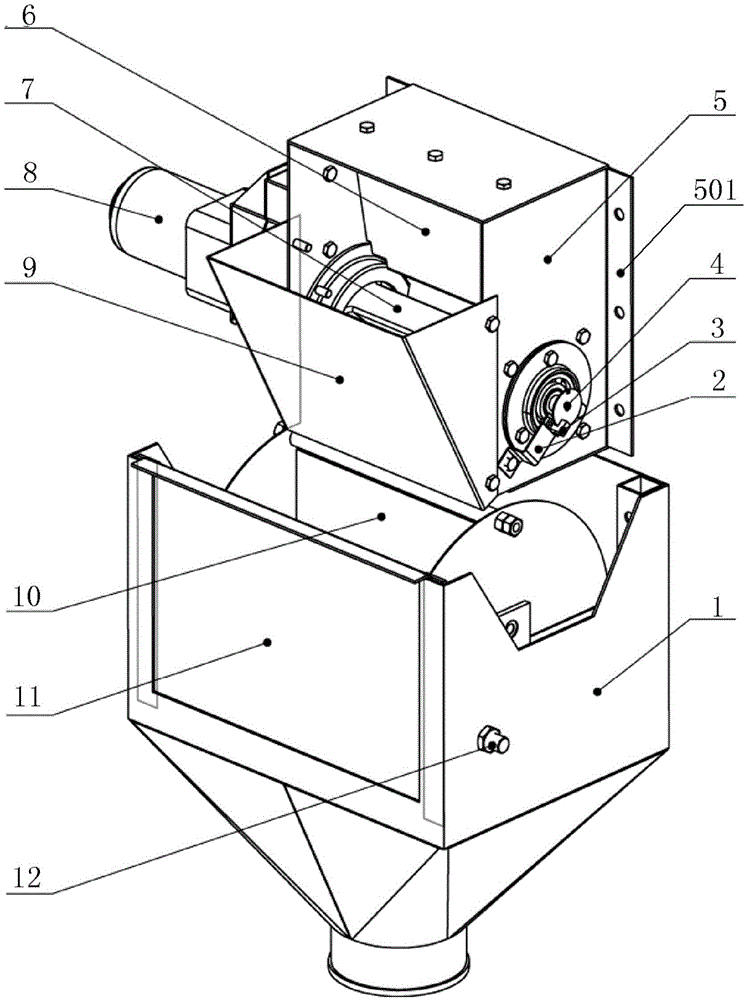

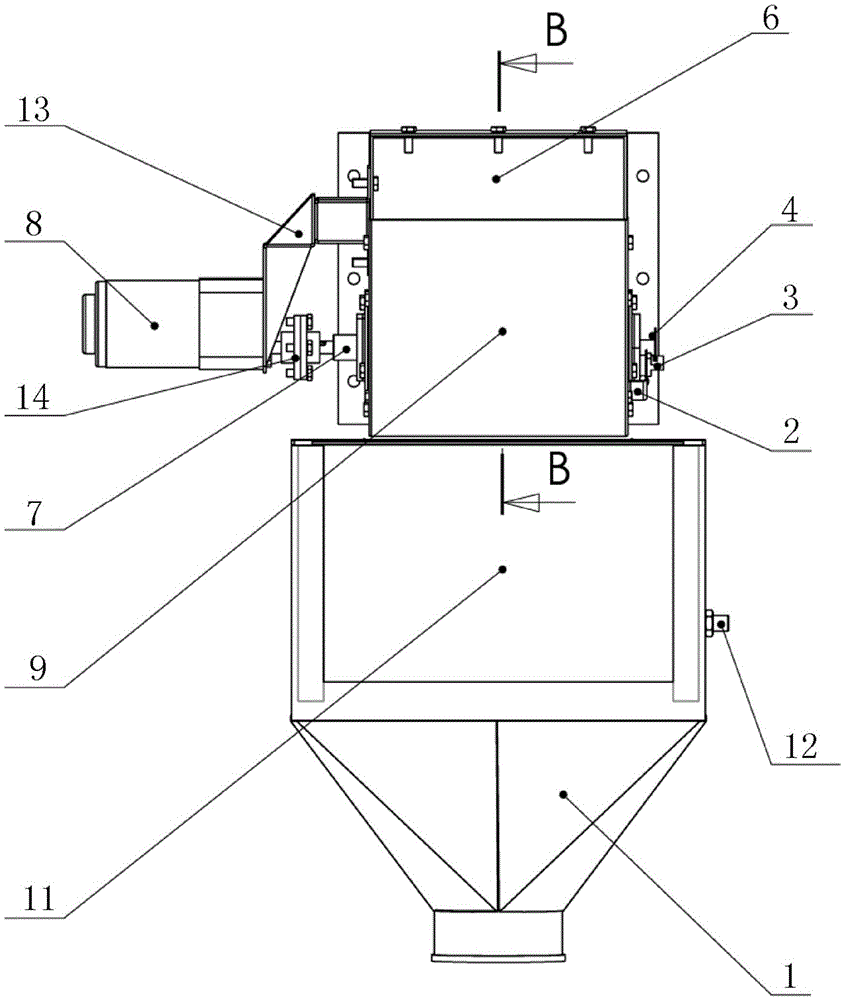

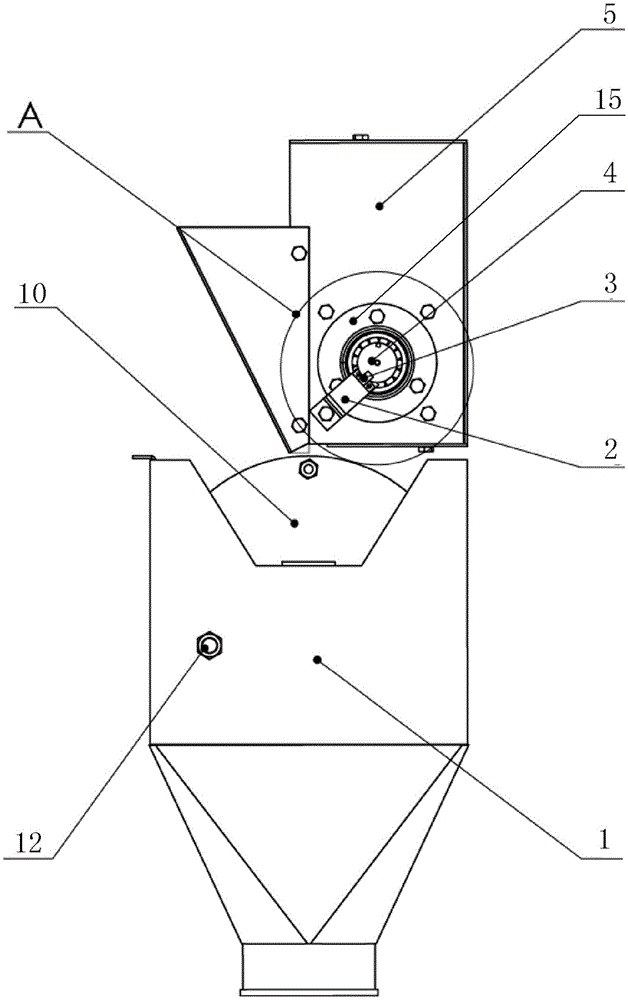

[0049] like Figure 1-Figure 3 As shown, the corn bulk density online detector includes a fixed-volume grain discharge mechanism 25 and a hopper 1. The fixed-volume grain discharge mechanism 25 and the hopper 1 are arranged up and down and installed in the slow-down section of the grain dryer 27. In the hopper 1 An automatic overturn weighing mechanism 26 is installed. The feed port 2501 of the fixed volume grain discharge mechanism 25 is docked with the discharge port located at the slow section of the grain dryer 27, and the discharge port 2502 of the fixed volume grain discharge mechanism 25 corresponds to the automatic flip weighing mechanism 26. Tipping bucket 10 middle part.

[0050]The fixed volume grain discharge mechanism 25 includes a grain discharge plate frame 5 fixed on the grain dryer 27 by bolts. The grain discharge plate frame 5 is a rectangular frame surrounded by thin plates for installing the grain discharge roller 7 . The rear ends of the two side plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com