Lithium ion battery module structure

A lithium-ion battery and module structure technology, applied in secondary batteries, structural parts, battery pack parts, etc., can solve the problems of unfavorable batch automatic production, high labor intensity of operators, complicated structure connection, etc., and reduce the assembly process. steps, the effect of ensuring electrical safety and stability, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

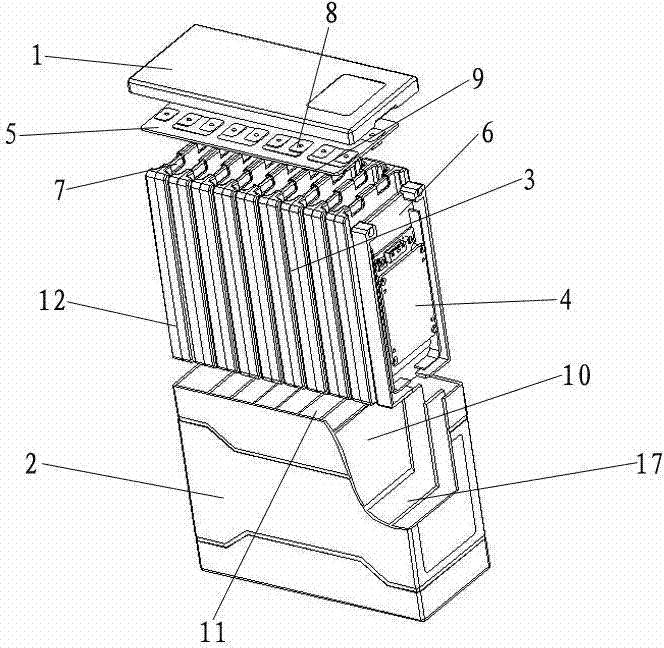

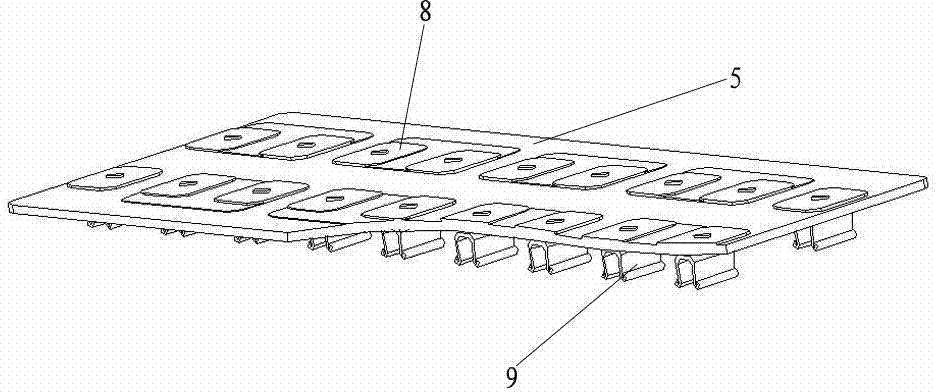

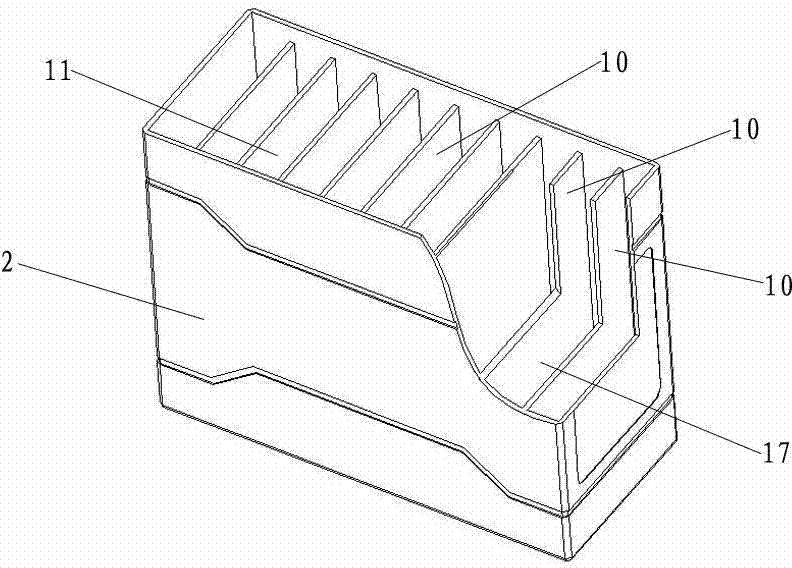

[0018] Such as figure 1 The shown lithium ion battery module structure of the present invention includes a top cover 1 , a bottom case 2 , a cell module 3 , a BMS management module 4 and a PCB adapter board 5 . As an implementation, such as image 3 As shown, positioning partitions 10 are provided on the inner bottom surface of the bottom case 2 , and slots 11 for accommodating unit batteries 12 are formed between the positioning partitions 10 . The cell module 3 is positioned and connected to the bottom case 2 through the slot 11 . The structure setting of the card slot 11 is simple and reliable. In order to facilitate the processing and manufacture, the positioning partition 10 and the bottom shell 2 can be provided as an integral injection molding structure. The unit cells 12 inside the cell module 3 are electrically connected through the PCB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com