Automatic bagging, opening bending and stick insertion all-in-one machine for edible mushrooms

An edible fungus and all-in-one technology, applied in the fields of application, horticulture, botanical equipment and methods, etc., can solve the problems of uneven size of mushroom sticks, non-standard position of inserting sticks, high infection rate of miscellaneous bacteria, etc. Effect of speed and yield, reduction of construction area, uniform growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

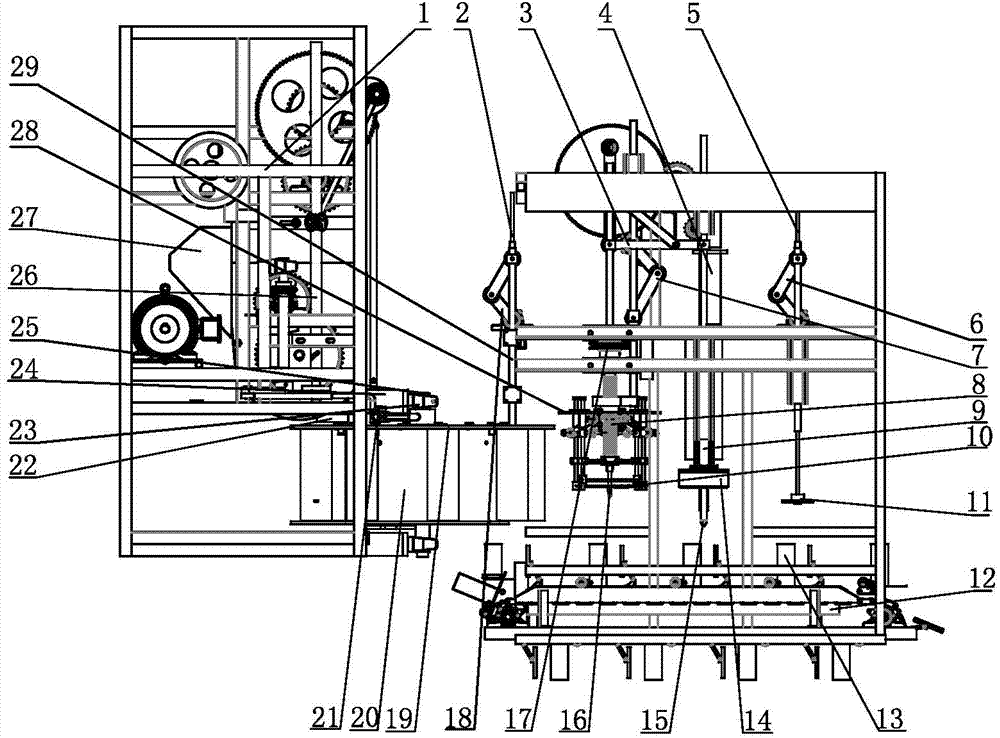

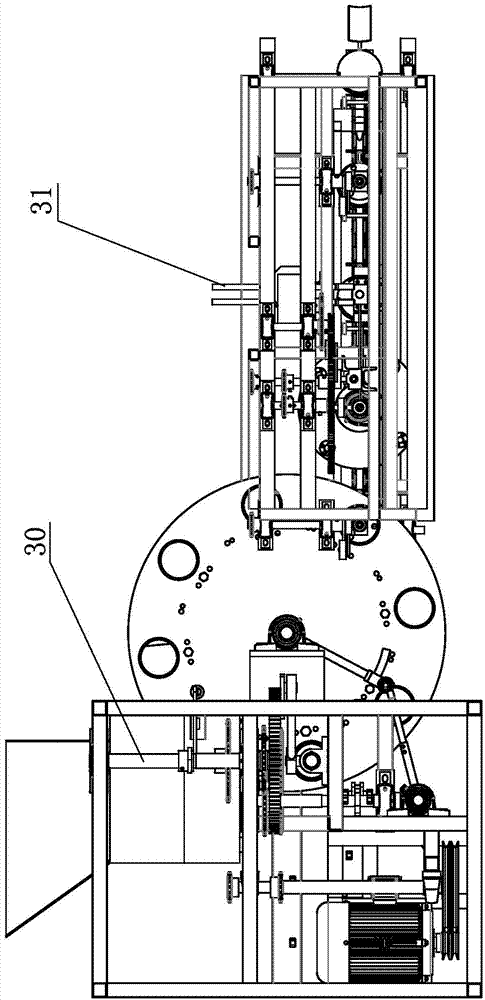

[0024] Such as figure 1 and figure 2 As shown, the edible fungus automatic bagging and inserting rod integrated machine includes a station conveyor 12, the station conveyor 12 is a chain transmission mechanism, and the corresponding station of the station conveyor 12 is provided with a holding tube 13, and the station On the top of the conveyor 12, there are successively a pressing bar moving unit 2, an automatic nest opening unit 3, an automatic rod inserting unit 4, and a pressing bar shaping unit 5, and an automatic bagging machine 1 is installed on the side of the pressing bar moving unit 2 .

[0025] Described automatic bagging machine 1 comprises feed bin 27, stamping device 26 and station turntable 19 successively from top to bottom, and the corresponding station of station turntable 19 is provided with forming barrel 20, and stamping device 26 and sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com