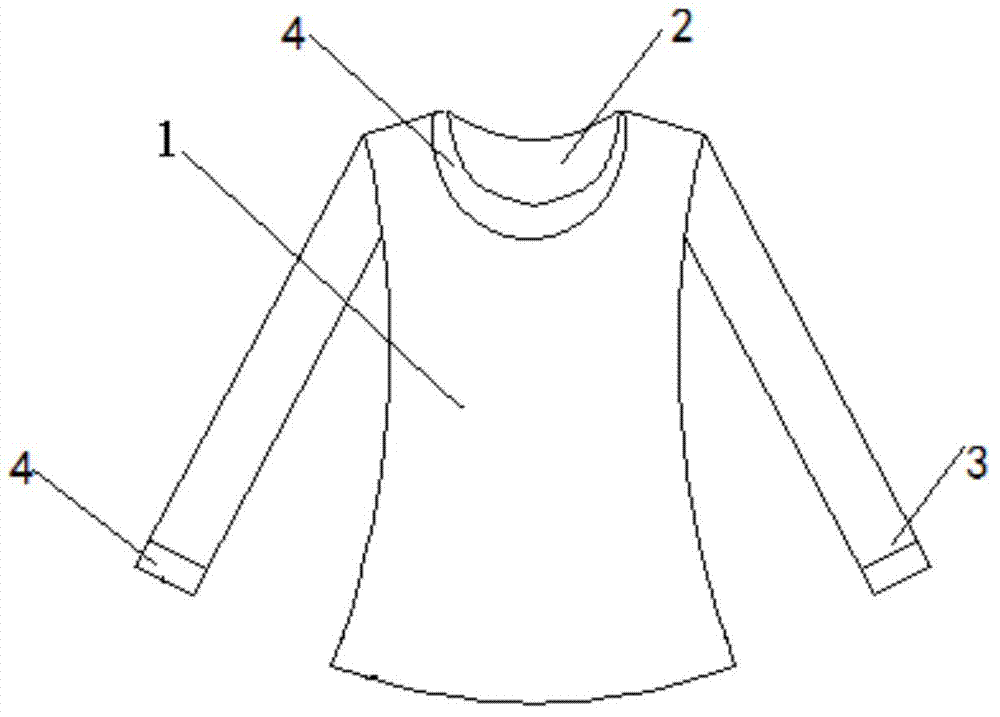

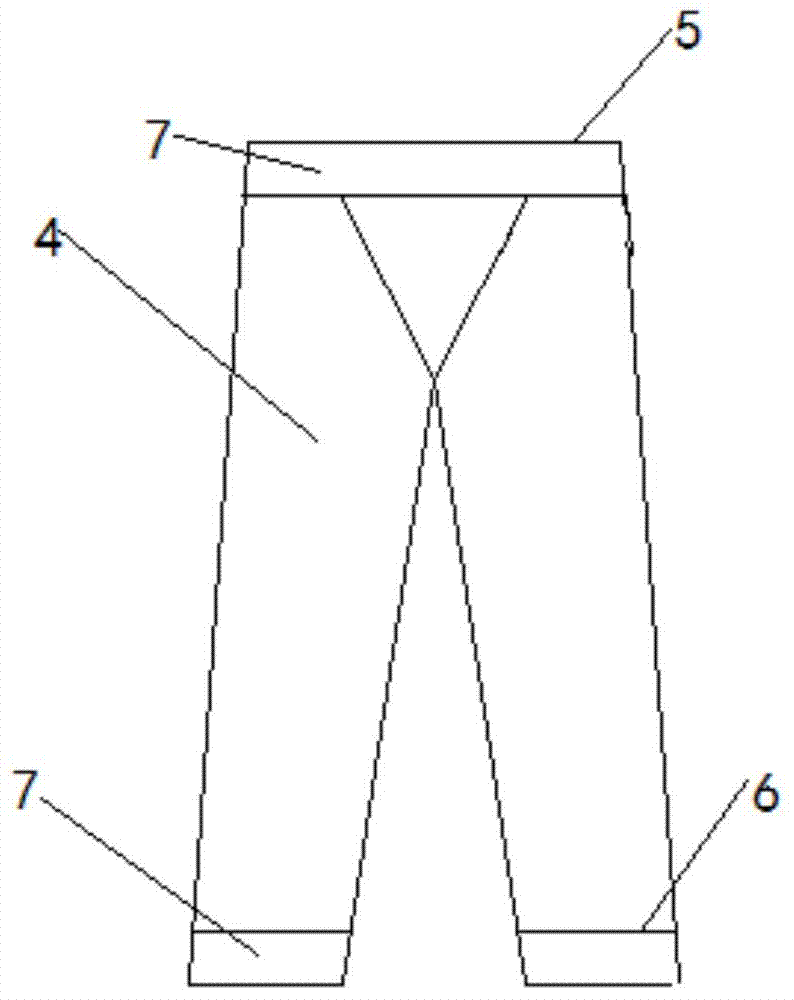

Underwear fabric and underwear

A technology for underwear and fabrics, applied in the field of clothing manufacturing, can solve problems such as easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The underwear fabric composition provided by the embodiment of the present invention includes: the underwear fabric is made of acrylic fiber, viscose fiber, modal fiber, cupro ammonia fiber, nylon, wool, spandex blended fabric, the content of acrylic fiber in the underwear fabric is 56%, and the content of viscose fiber in the underwear fabric is 56%. The content in the fabric is 19%, the content of modal fiber and copper ammonia fiber in the underwear fabric is 14%, the content of nylon in the underwear fabric is 5%, the content of wool in the underwear fabric is 4%, and the spandex in the underwear fabric The content in is 2%.

[0031] The underwear fabric with the above structure makes full use of the thermal performance of acrylic fiber and wool, the moisture absorption performance of viscose fiber, the air permeability of modal fiber and cupro ammonia fiber, the strong and wear-resistant performance of nylon fiber, and the elastic performance of spandex, so that the...

Embodiment 2

[0033] The underwear fabric components provided by the embodiment of the present invention include: the underwear fabric is made of acrylic fiber, viscose fiber, modal fiber, cupro ammonia fiber, nylon, wool, spandex blended fabric, the content of acrylic fiber in the underwear fabric is 55.2%, and the content of viscose fiber in the underwear fabric is 55.2%. The content in the fabric is 18.6%, the content of modal fiber and copper ammonia fiber in the underwear fabric is 14.6%, the content of nylon in the underwear fabric is 5.5%, the content of wool in the underwear fabric is 4.8%, and the spandex in the underwear fabric The content in is 1.3%.

[0034] The underwear fabric with the above structure makes full use of the thermal performance of acrylic fiber and wool, the moisture absorption performance of viscose fiber, the air permeability of modal fiber and cupro ammonia fiber, the strong and wear-resistant performance of nylon fiber, and the elastic performance of spandex,...

Embodiment 3

[0036] The underwear fabric composition provided by the embodiment of the present invention includes: the underwear fabric is made of acrylic fiber, viscose fiber, modal fiber, cupro ammonia fiber, nylon, wool, spandex blended fabric, the content of acrylic fiber in the underwear fabric is 55%, and the content of viscose fiber in the underwear fabric is 55%. The content of the fabric is 18%, the content of modal fiber and copper ammonia fiber in the underwear fabric is 15%, the content of nylon in the underwear fabric is 6%, the content of wool in the underwear fabric is 5%, and the spandex in the underwear fabric The content in is 1%.

[0037] The underwear fabric with the above structure makes full use of the thermal performance of acrylic fiber and wool, the moisture absorption performance of viscose fiber, the air permeability of modal fiber and cupro ammonia fiber, the strong and wear-resistant performance of nylon fiber, and the elastic performance of spandex, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com