Heat recovery type bathing machine

A bathing machine and heat recovery technology, applied in fluid heaters, lighting and heating equipment, household appliances, etc., can solve the problems of slow heat rise, low utilization rate of hot sewage, loss of heat from sewage, etc., and improve energy utilization efficiency. , The effect of energy saving is obvious, and the effect of reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

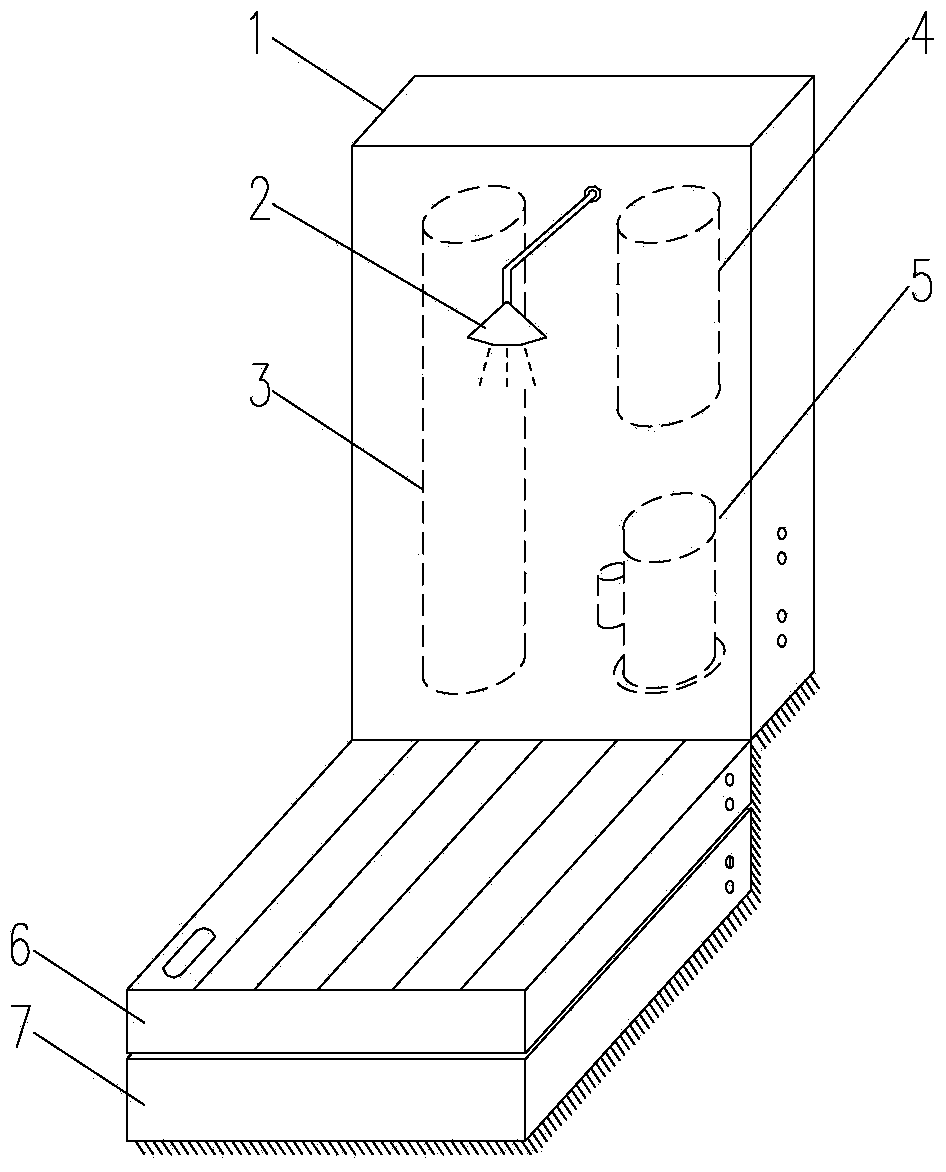

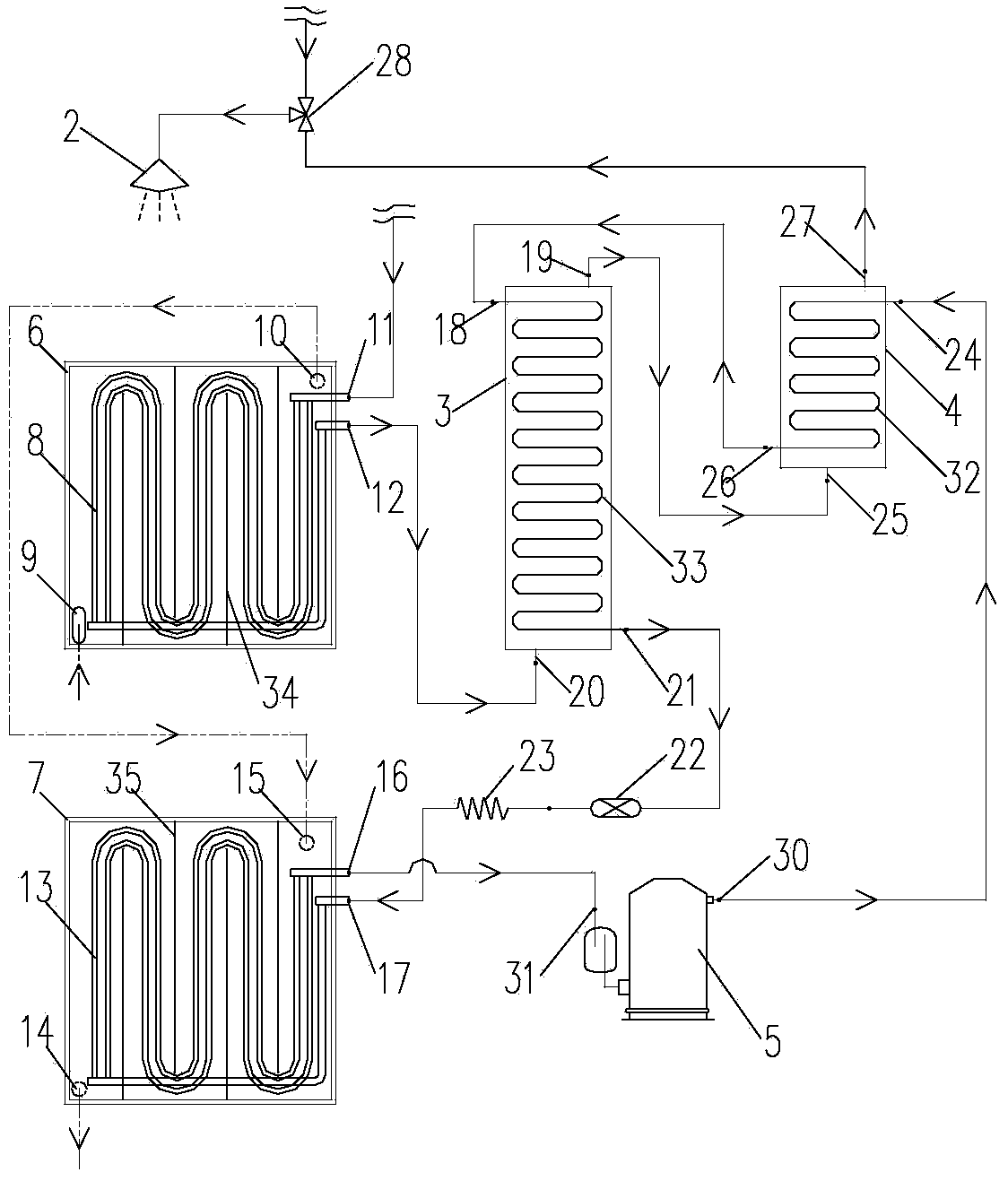

[0017] Example 1: as attached figure 1 The shown heat recovery type bathing machine includes three parts: a main machine box 1, a bath table recovery box 6, and an evaporation box 7. The main engine box 1 and the recovery box 6 of the bathing platform are diagonally arranged, and the evaporation box 7 is located directly below the recovery box 6 of the shower platform; The heated clear water that sprays out from the nozzle 2 becomes hot sewage after use, and directly flows into the sewage inlet of the recovery box 6 of the bathing platform.

[0018] The main box includes: nozzle 2, water mixing valve 28, compressor 5, filter 22, capillary 23, medium temperature water tank 3, high temperature water tank 4, medium temperature water tank 3 is provided with heat exchange coil 4 33, high temperature water tank 4 is provided with a heat exchange coil three 32; the bath table recovery box 6 is provided with a heat exchange coil one 8, and the evaporation box 7 is provided with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com