Automatic bearing race rust preventing workstation

A technology for bearing rings and workstations, which is applied in coatings and devices for coating liquid on the surface, etc., can solve the problems of low efficiency of manual oiling and waste of oil, etc., and achieve the goals of improving oiling efficiency, not easy to leak coating, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

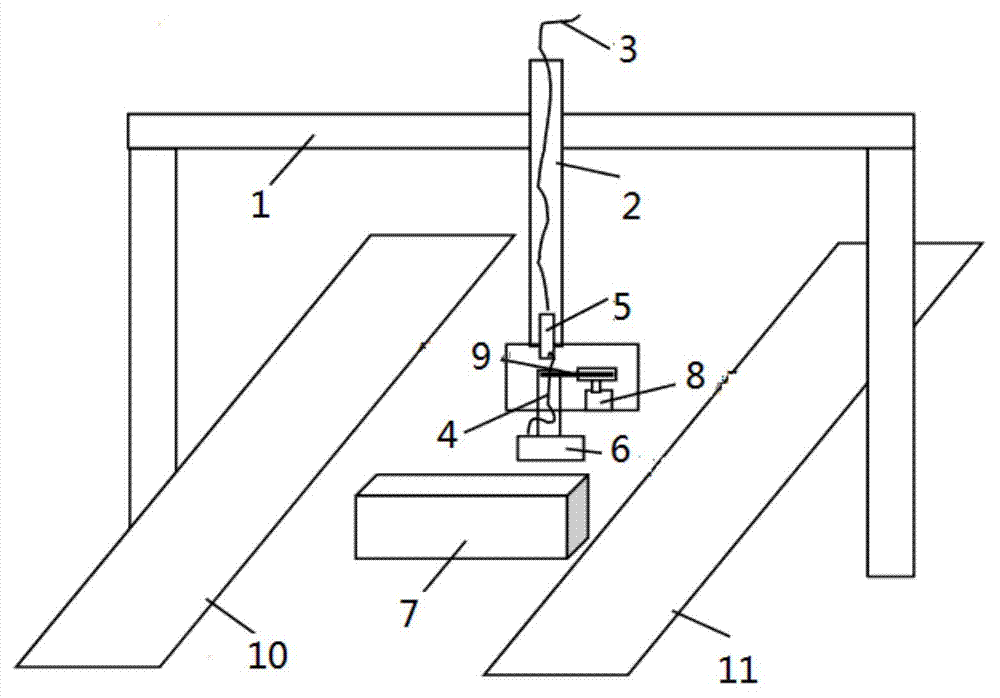

[0018] Such as figure 1 , the present invention includes a horizontal moving unit 1, a vertical moving unit 2, a first air pipe 3, a second air pipe 4, a rotary air joint 5, an air claw 6, an oil pool 7, a motor 8 and a transmission belt 9; the horizontal moving unit 1 drives the vertical The straight moving unit 2 moves horizontally, the fixed part of the rotary air joint 5 is fixed on the vertical mobile unit 2, the rotating part of the rotary air joint 5 is fixedly connected with the air claw 6, and the oil pool 7 is located below the air claw 6, The first air pipe 3 is connected to the air inlet located at the fixed part of the rotary air joint 5, the air outlet located at the rotating part of the rotary air joint 5 is connected to the air inlet of the air gripper 6 through the second air pipe 4, and the motor 8 is driven to rotate by the transmission belt 9 The rotating part of the air joint 5, the air claw 6 and the second air pipe 4 rotate together, and the vertical mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com