Method for improving yield of qualified sized casting blanks at casting stop stage of continuous casting machine

A continuous casting machine and stage technology, which is applied in the field of continuous casting control, can solve the problems such as affecting the economic benefit of the product quality enterprise, affecting the qualified rate of cast slab production with fixed length, and the length does not meet the fixed length requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

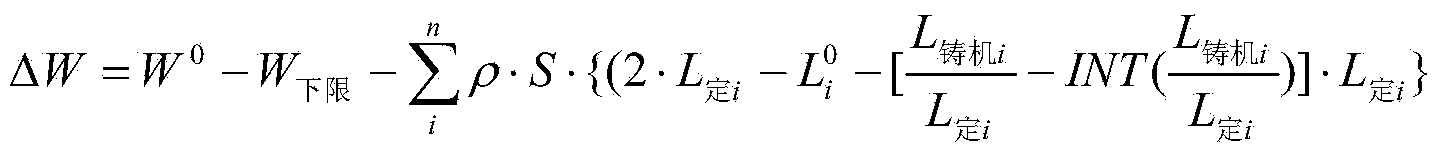

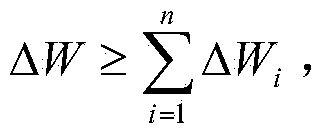

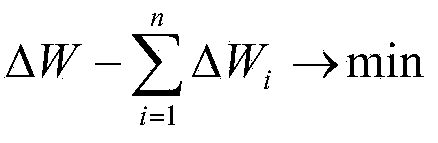

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Take the currently more popular 8-strand continuous casting machine as an example:

[0071] It is spring at this time, and all 8 streams of the continuous caster are working normally.

[0072] Before the continuous casting machine enters the stop-pouring state, the on-site operators measure the temperature and weight of the molten steel in the tundish. The temperature of the molten steel is detected at 1550°C, and the weight of the molten steel is 38000kg. After the detection is completed, the intelligent stop-pouring control system for billet continuous casting is activated, and the molten steel temperature and weight information in the tundish will be automatically entered into the system.

[0073] According to the requirements of the process regulations, the lower limit weight of the tundish molten steel W Lower limit Set to 15000kg, set the lower limit temperature of the tundish molten steel T Lower limit Set it to 1520℃, and set the temperature drop rate of molten steel i...

Embodiment 2

[0108] Take the currently more popular 8-strand continuous casting machine as an example:

[0109] It is summer, and 7 streams of the continuous casting machine are working normally, namely 1#, 2#, 4#, 5#, 6#, 7#, 8#, and the 3# nozzle is not turned on. The priority distribution rights of molten steel for each nozzle of the continuous casting machine are: 4#>5#>6#>2#>7#>1#>8#.

[0110] Before the continuous casting machine enters the stop state, the on-site operators measure the temperature and weight of the molten steel in the tundish. The temperature of the molten steel is detected at 1560℃, and the weight of the molten steel is 38000kg. After the detection is completed, the billet continuous casting is started and stopped. Pouring control system, at this time the molten steel temperature and weight information in the tundish will be automatically input into the system.

[0111] According to the requirements of the process regulations, the lower limit weight of the tundish molten ...

Embodiment 3

[0144] Take the currently more popular 8-strand continuous casting machine as an example:

[0145] It is winter at this time, and 6 streams of the continuous casting machine are working normally, namely 1#, 2#, 5#, 6#, 7#, 8#, and the nozzles of 3# and 4# are not opened. The priority distribution right of molten steel at the water outlet is: 5#>6#>2#>7#>1#>8#.

[0146] Before the continuous casting machine enters the stop-pouring state, the on-site operators measure the temperature and weight of the molten steel in the tundish. The temperature of the molten steel is detected at 1560°C, and the weight of the molten steel is 38,000 kg. After the detection is completed, the billet continuous casting stop-pouring control system is activated, and the molten steel temperature and weight information in the tundish will be automatically input into the system.

[0147] According to the requirements of the process regulations, the lower limit weight of the tundish molten steel W Lower limit S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com