Mechanical gripper for material feeding of material mixer

A technology of mechanical grippers and mixers, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as hazards, heavy loads, and harmful to workers' health, and achieve accurate feeding, high production efficiency, and stable and reliable grasping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific technical solutions of the present invention will be briefly described below in conjunction with the accompanying drawings.

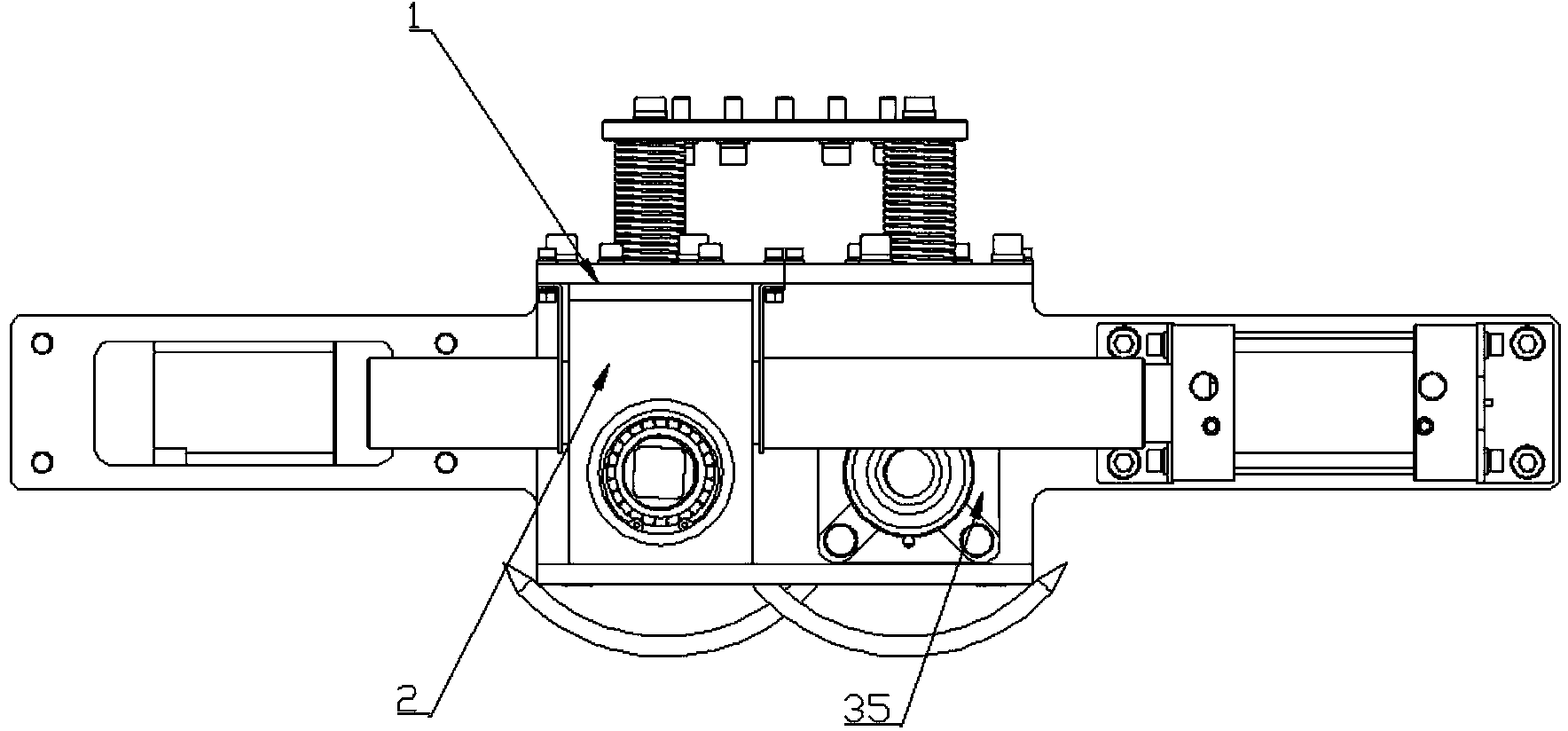

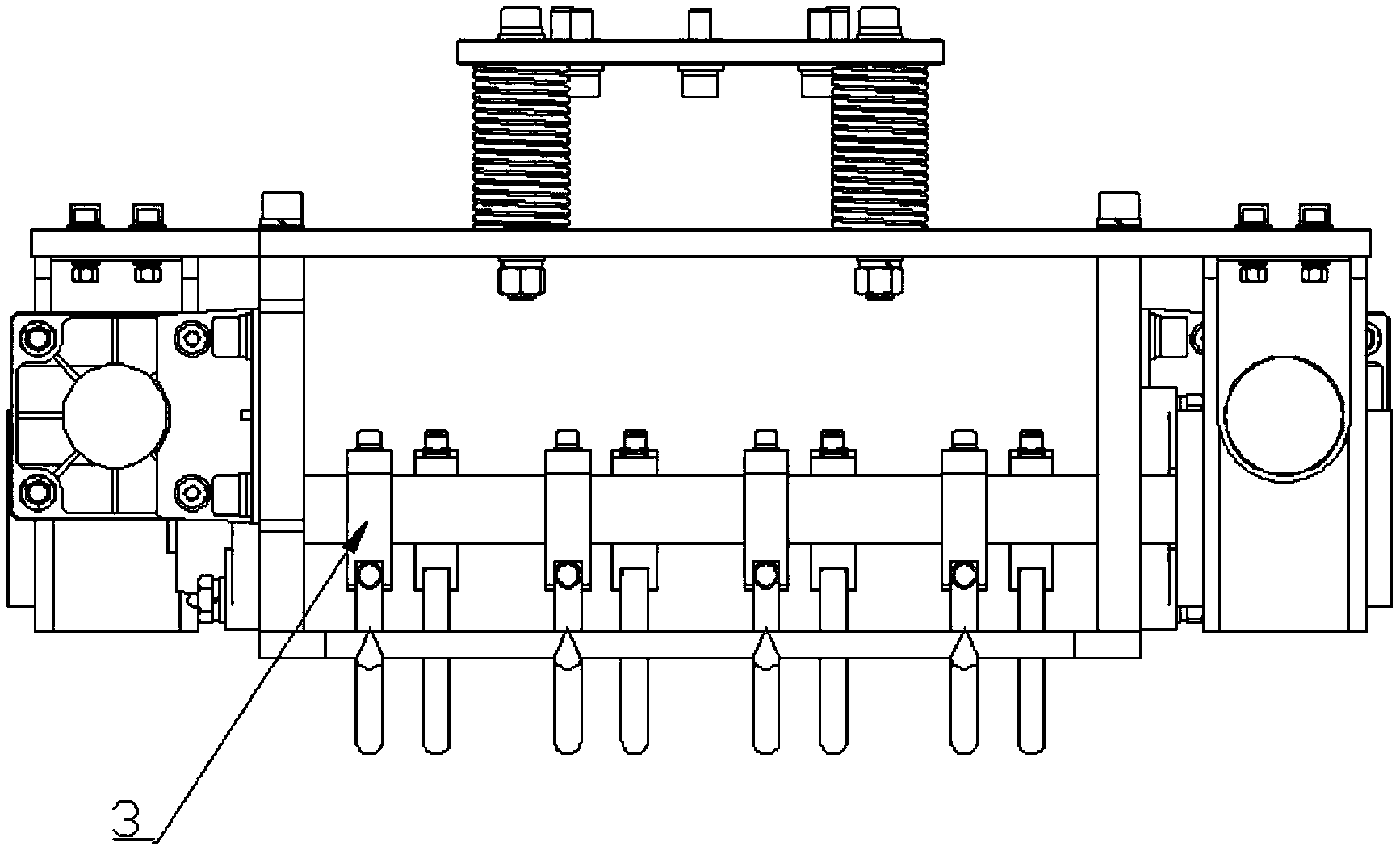

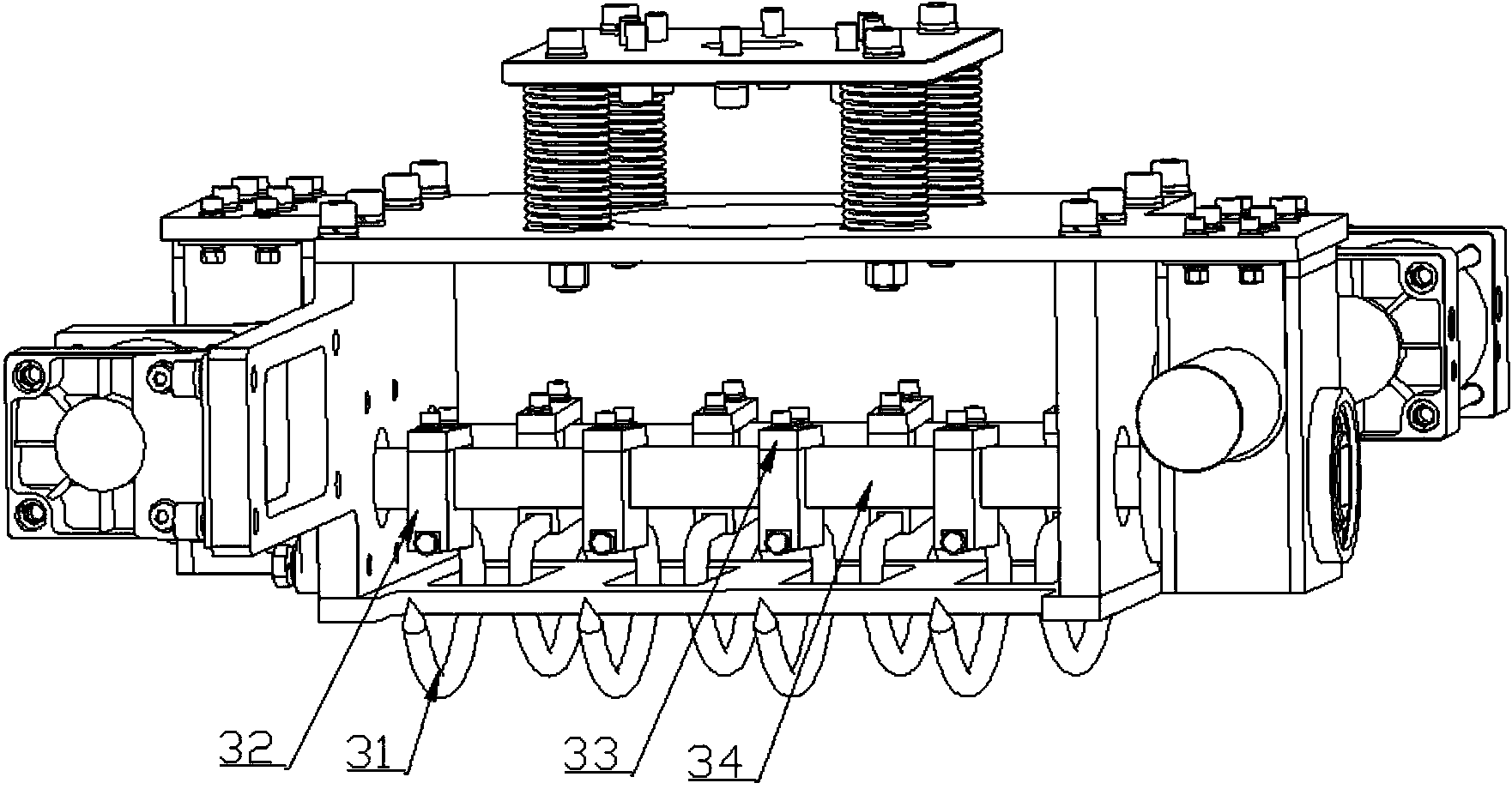

[0023] Such as Figure 1-2 As shown, a mechanical gripper for mixing machine feeding according to the embodiment of the present invention is mainly composed of three parts: the main frame assembly 1, the transmission assembly 2 and the grabbing hook assembly 3, wherein the main frame assembly 1 is mainly used to support the transmission The assembly 2 and the grapple assembly 3 are provided with a main shaft 34 inside the main frame assembly 1 . The transmission assembly 2 mainly controls the transmission of the rack 25 and the gear 26 through the opening and closing of the cylinder 22 fixed on the side plate 15 of the main frame assembly 1, thereby driving the grasping and throwing actions of the grapple assembly 3 . The grapple assembly 3 is made up of several evenly distributed grapple 31 assemblies, and the grapple assembly 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com