Injection molding method of fiber network-containing plastic board

A technology of injection molding and fiber net, which is applied in the direction of coating, etc., can solve the problems of building formwork strength decrease, reinforcement effect not as good as reinforcement effect, and easy occurrence of floating fibers, etc., to improve service life, avoid interface peeling, and ensure strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

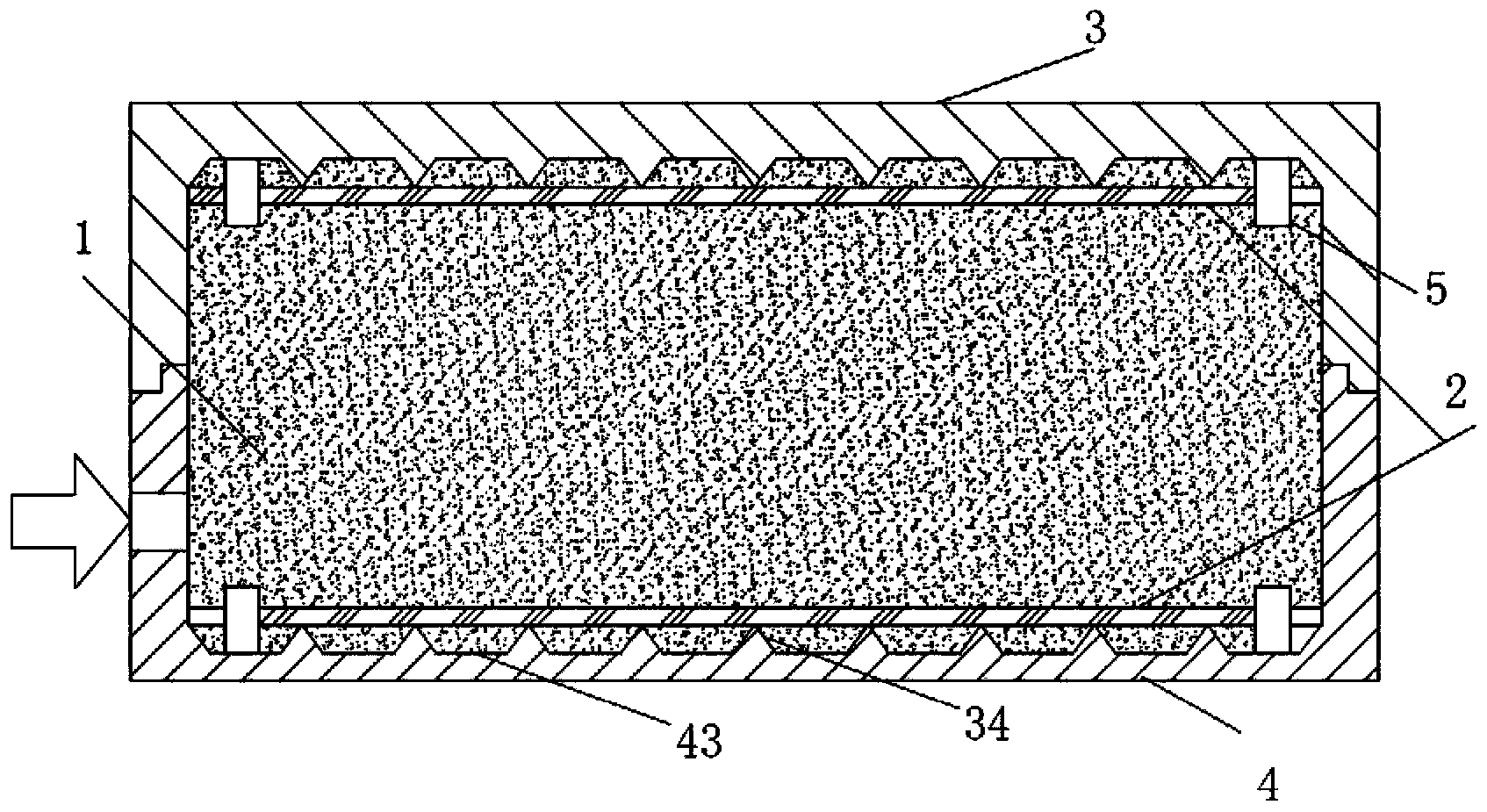

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0021] The invention is an injection molding method of a plastic sheet containing a fiber net, comprising the following steps:

[0022] S1. Melt, extrude, cool, and cut waste plastic into uniform plastic particles through a twin-screw extruder;

[0023] S2. Crushing waste rubber into rubber granules and / or rubber powder;

[0024] S3. uniformly mixing rubber granules and / or rubber powder with an auxiliary agent accounting for 1 to 15% of the rubber weight to obtain a mixture of rubber and auxiliary agent;

[0025] S4. Extrude and pelletize the mixture of rubber and additives from the machine head after kneading by mixing equipment to obtain rubber modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com