Hard coating and manufacturing mehtod

A manufacturing method and hard coating technology, which can be used in chemical instruments and methods, other household appliances, instruments, etc., can solve problems such as difficult to print, and achieve excellent scratch resistance and good writing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

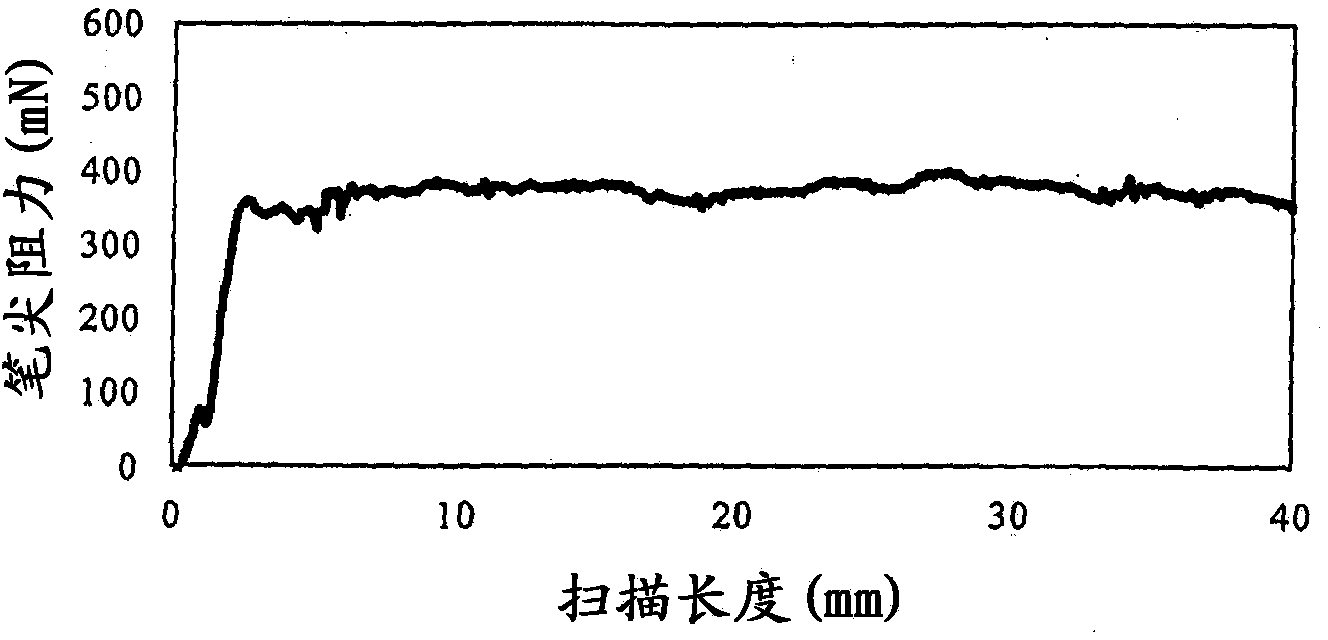

Image

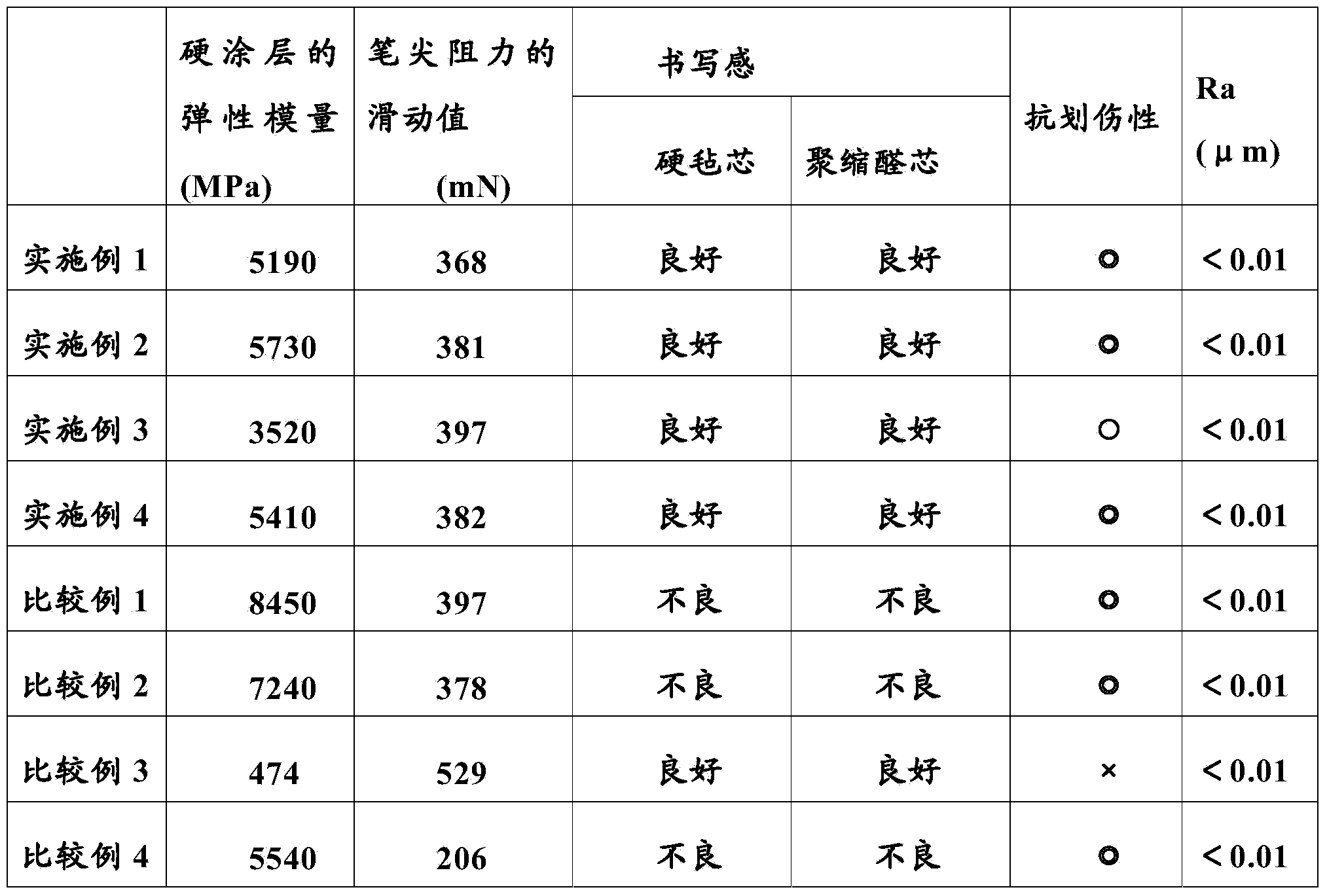

Examples

Embodiment 1

[0089] Ethoxylated dipentaerythritol hexaacrylate (manufactured by Shin Nakamura Chemical Industry Co., Ltd., NK Ester A-DPH-12E, which is a polyfunctional (meth)acrylate having a plurality of ethylene oxide units, ethylene oxide in 1 molecule Amount of alkane unit: 12 mol) 50 parts by mass (represented in terms of solid content. Hereinafter, the same applies to other components.); Pentaerythritol triacrylate ( New Nakamura Chemical Industry System, NK Ester A-TMM-3L) 50 mass parts; 1-hydroxycyclohexyl phenyl ketone (BASF company system, イルガキュア 184) 10 mass parts as photopolymerization initiator; 0.1 parts by mass of a polysiloxane-modified acrylic polymer (silicon-based leveling agent; BYK-3550 manufactured by Bicchem Corporation) was mixed to obtain a coating composition. This coating composition was diluted with propylene glycol monomethyl ether to prepare a coating liquid having a solid content concentration of 30%. In addition, based on the said compounding, the quantity...

Embodiment 2

[0098] Ethoxylated dipentaerythritol hexaacrylate (manufactured by Shin Nakamura Chemical Industry Co., Ltd., NK Ester A-DPH-12E, which is a polyfunctional (meth)acrylate having a plurality of ethylene oxide units, ethylene oxide in 1 molecule The amount of alkylene units present: 12 moles) was changed to 30 parts by mass, and pentaerythritol triacrylate (manufactured by Shin Nakamura Chemical Industries, NK Ester A- Except having changed the compounding quantity of TMM-3L) into 70 mass parts, and having formed a hard coat layer, it carried out similarly to Example 1, and manufactured the hard coat film. In addition, the quantity of the ethylene oxide unit in the total amount of polyfunctional (meth)acrylate was 15 mass % from said compounding.

Embodiment 3

[0100] Ethoxylated dipentaerythritol hexaacrylate (manufactured by Shin Nakamura Chemical Industry Co., Ltd., NK Ester A-DPH-12E, which is a polyfunctional (meth)acrylate having a plurality of ethylene oxide units, ethylene oxide in 1 molecule The amount of alkylene units present: 12 moles) was changed to 100 parts by mass, and pentaerythritol triacrylate (manufactured by Shin Nakamura Chemical Industries, NK Ester A- Except having changed the compounding quantity of TMM-3L) into 0 mass part, and having formed a hard coat layer, it carried out similarly to Example 1, and manufactured the hard coat film. In addition, the quantity of the ethylene oxide unit in the total amount of polyfunctional (meth)acrylate was 48 mass % from the said compounding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com