An electric vehicle driven by multiple power sources and multiple motors

A multi-motor drive, electric vehicle technology, applied in the direction of electric vehicles, electric traction, vehicle energy storage, etc., can solve the problems of difficult production, insufficient torque, reduced utilization rate, etc., to reduce technical difficulty and safety hazards, electric The effect of reducing the requirements of core performance and reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

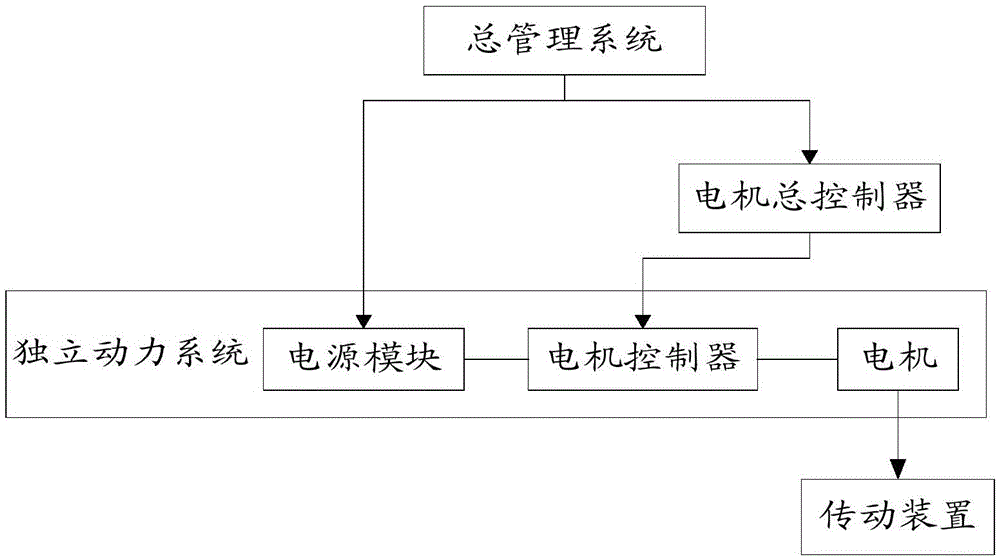

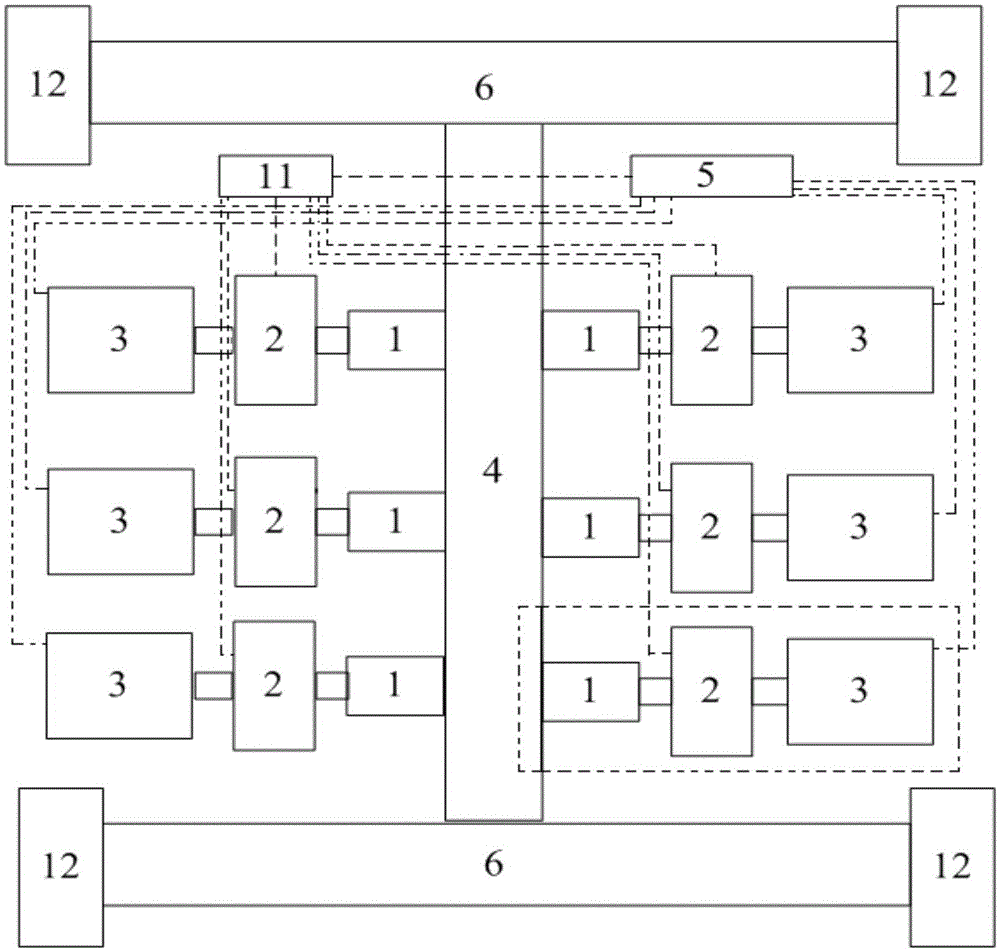

[0035] refer to figure 1 , figure 2 and Figure 5 , specific embodiment 1, an electric vehicle driven by multiple power supplies and multiple motors, the electric vehicle includes a car body 10, wheels 12 installed at the bottom of the car body 10, and multiple power supplies connected to the wheels 12. motor drive;

[0036] Described multi-power supply multi-motor driving device comprises: total management system 5, motor total controller 11, transmission device and 6 independent power systems; Described total management system 5 is connected with described independent power system and motor total controller 11, the independent power system is respectively connected with the motor master controller 11 and the transmission device, any two independent power systems are connected in parallel, and the transmission device is connected with the wheel 12.

[0037] The transmission device is a transmission shaft 4, and the moment is acted on the transmission shaft 4 by using a on...

specific Embodiment approach 2

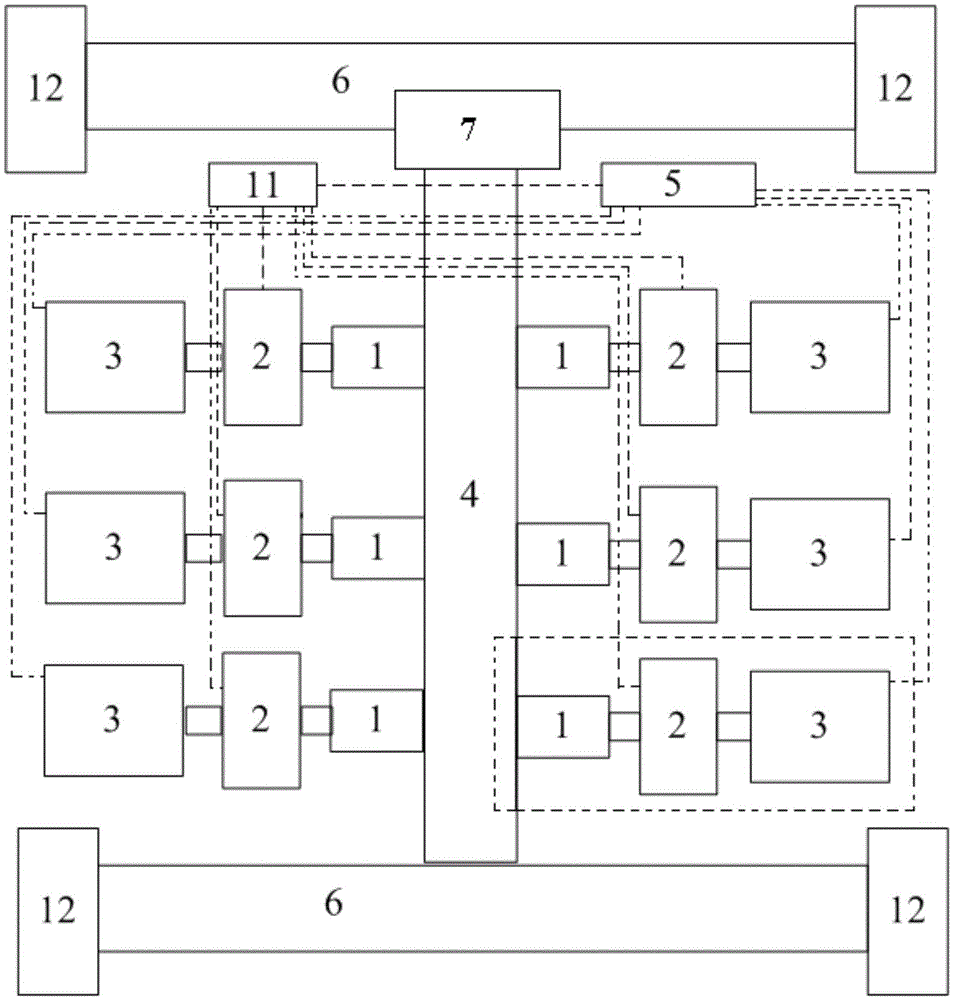

[0058] refer to figure 1 , image 3 and Figure 5 , Specific embodiment 2, the difference between this embodiment and specific embodiment 1 is that the transmission device is a combination of the connection between the gearbox 6 and the transmission shaft 4, and the torque is jointly acted on a single shaft by using a one-way clutch On the drive shaft, the power is transmitted to the wheels to make the wheels run.

[0059] In this specific embodiment, the total voltage of the power module 3 is 72V.

[0060] This specific embodiment includes 6 independent power systems, and any two independent power systems are connected in parallel.

[0061] In this specific embodiment, the power supply module includes two independent power supplies, and the two independent power supplies are connected in parallel.

[0062] This specific embodiment adopts a plurality of motors, utilizes the one-way clutch to act on the torque together on a transmission shaft, and the transmission shaft is ...

specific Embodiment approach 3

[0063] refer to figure 1 , Figure 4 and Figure 5 , specific embodiment 3, the difference between this embodiment and specific embodiment 1 is that the transmission device is two transmission shafts, wherein, one transmission shaft 4-1 is connected with two front wheels 12-1, and the other A transmission shaft 4-2 is connected with two rear wheels 12-2, and each transmission shaft is provided with two independent power systems.

[0064] In this specific embodiment, the total voltage of the power module 3 is 96V.

[0065] In this specific embodiment, two high-speed motors 1-1 are connected on the transmission shaft 4-2 connecting the two front wheels 12-1, and two high-speed motors 1-1 are connected on the transmission shaft 4-2 connecting the two rear wheels 12-2. The electric motor 1-2 of low-speed high-torque characteristic.

[0066] In this specific embodiment, the two front wheels and the two rear wheels are equipped with two independent motors, and each motor is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com