Automatic bobbin sorting-arranging machine

An automatic sorting and tube management machine technology, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc., can solve the problems of bobbin scrapping, easily broken bobbin, bobbin impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

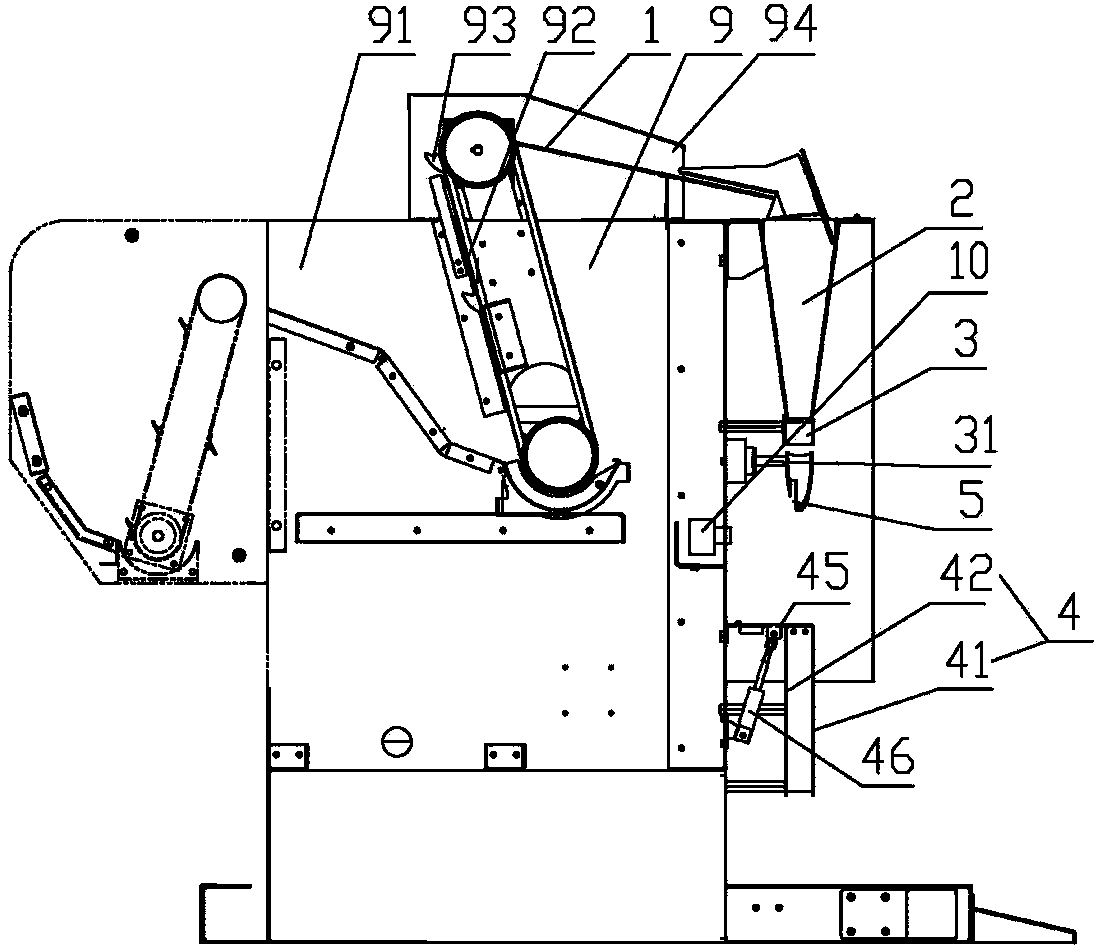

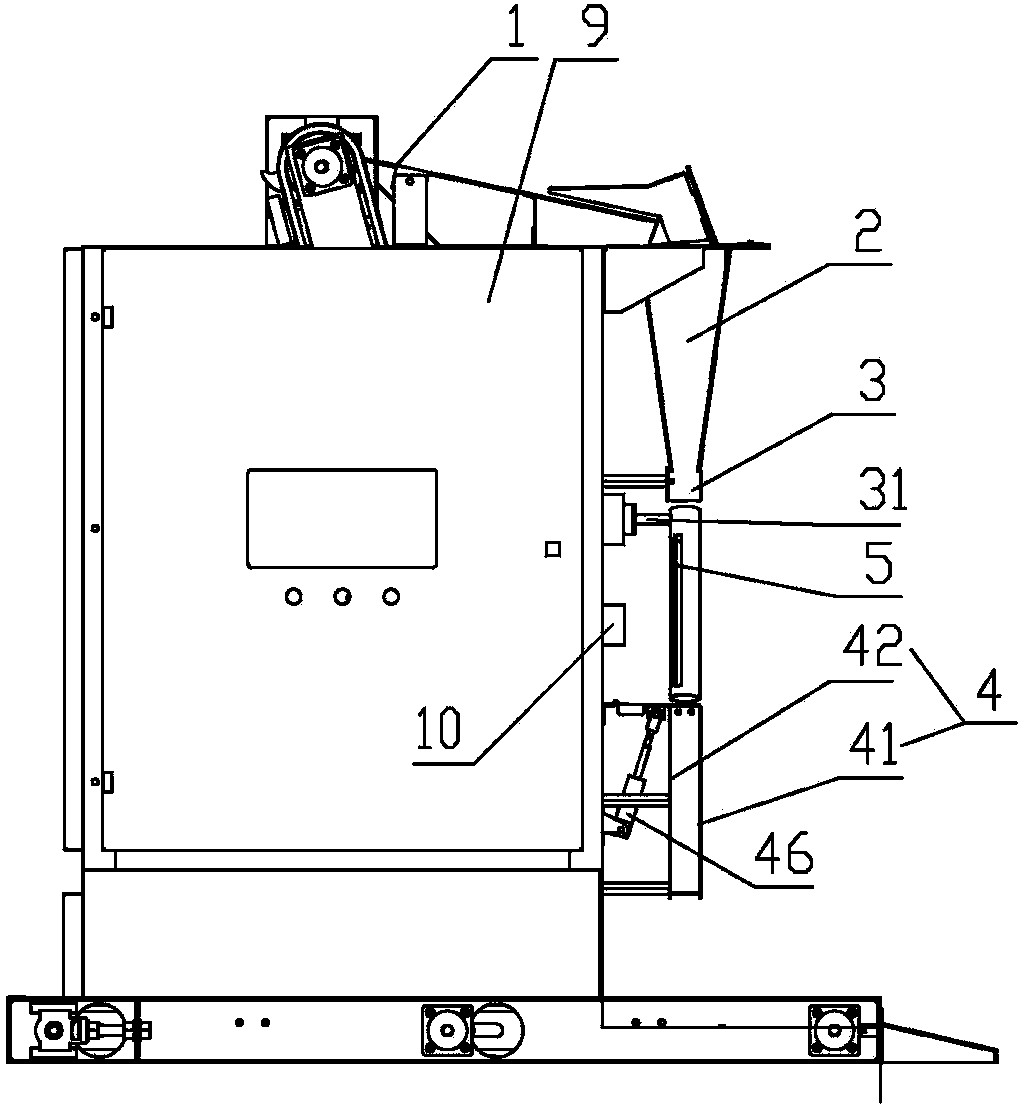

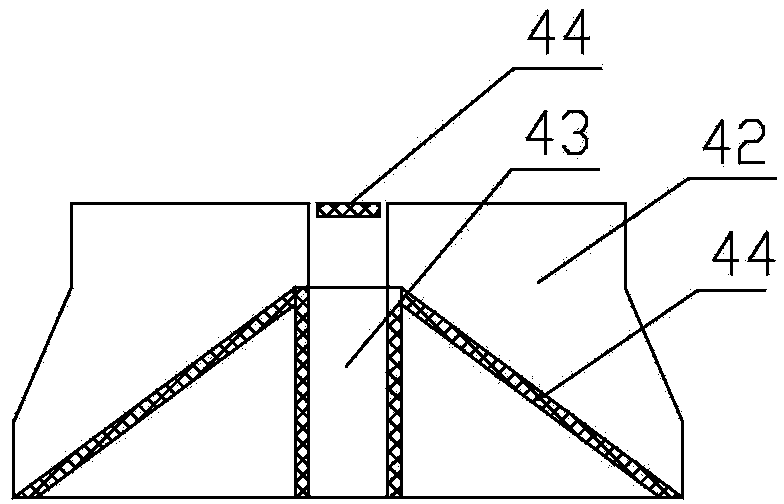

[0013] Such as figure 1 As shown, the bobbin automatic sorting and management machine of the present invention includes a frame 9, a feeding mechanism arranged on the frame 9, a rolling platform 1 at the top of the frame 9 inclined to be arranged, and a rolling platform 1 arranged on the rolling platform 1. The guide pipe 2, the identification pipe 3 and the sorter 4 at the end, the width of the rolling platform 1 is greater than the length of the bobbin. The feeding mechanism includes a silo 91 and a conveyor belt 92 arranged in the silo 91 , the upper end of the conveyor belt 92 is docked with the upper end of the rolling platform 1 . The conveyer belt 92 is longitudinally arranged, and the lower end of the conveyer belt 92 is positioned at the bottom of the feed bin 91, and the outer surface of the conveyer belt 92 is provided with a grabber 93 for grabbing bobbins; Plate 94. When the conveyor belt 92 moves under the drive of the drive roller, the bobbin can be lifted up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com