Method and device for producing bromine from brominated butyl rubber wastewater through steam distillation

A technology of bromobutyl rubber and bromine vapor, which is applied in the direction of bromine/hydrogen bromide, can solve the problems of environmental pollution, repair resource waste, etc., and achieve the effect of prolonging the cleaning cycle, reducing enterprise costs, and increasing surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

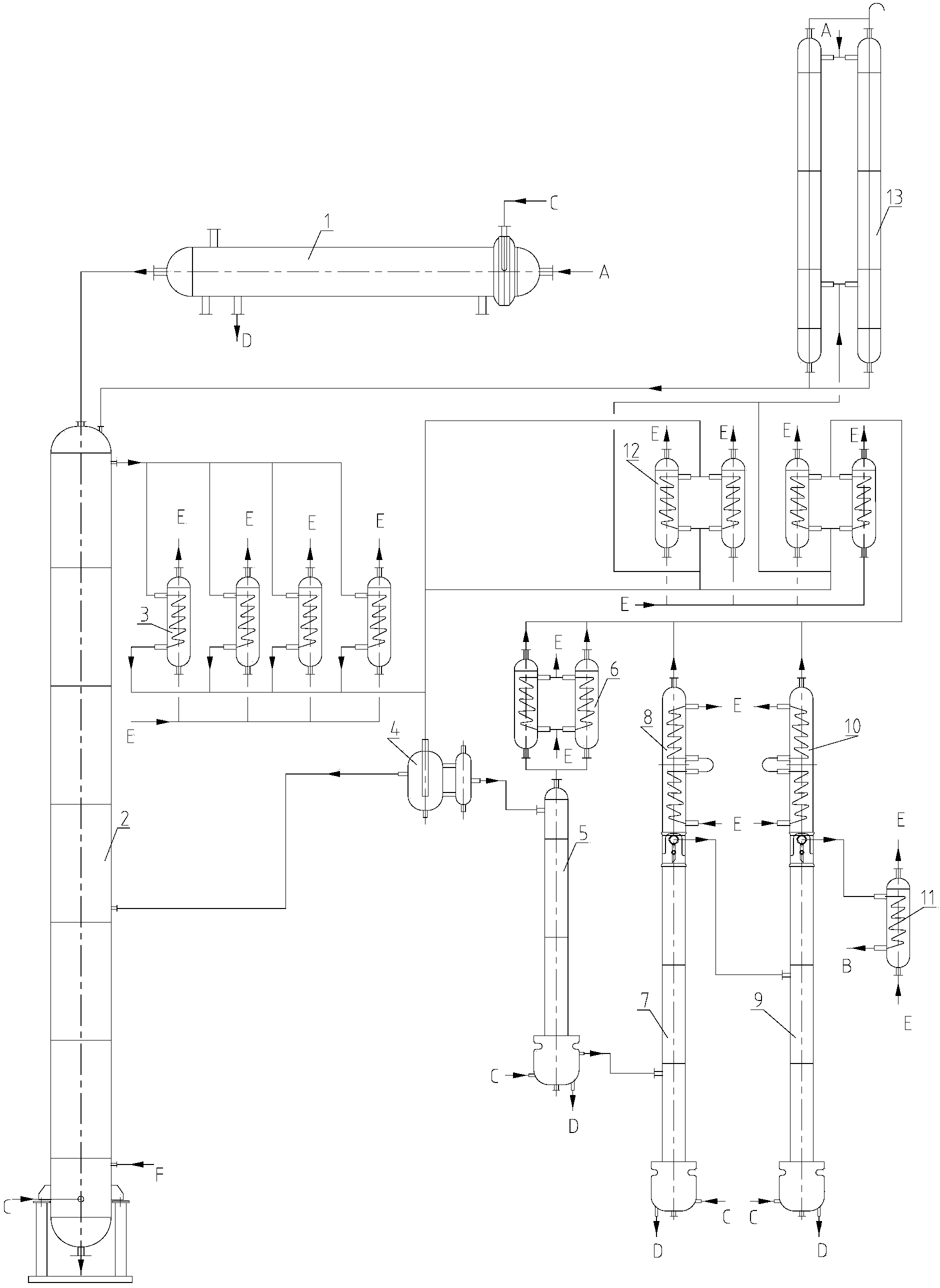

[0022] Such as figure 1 Shown:

[0023] Wastewater from the production of bromobutyl rubber first enters the preheater 1 for preheating, and then enters the distillation tower 2 from the top, while chlorine and steam enter the distillation tower 2 from the bottom, and the bromine vapor obtained after the reaction is composed of part of water vapor and chlorine The crude bromine vapor enters the bromine steam condenser 3 together, and the liquid after being condensed by cooling water enters the bromine water separator 4, and bromine and bromine water are separated in the separator, and the bromine water returns to the middle part of the distillation tower 2, and the crude bromine after separation Enter the next rectification process from the separator, and the non-condensable gas enters the non-condensable gas condenser 12 . The crude bromine obtained after being separated from the bromine water separator 4 enters from the top of the primary rectification tower 5 . After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com