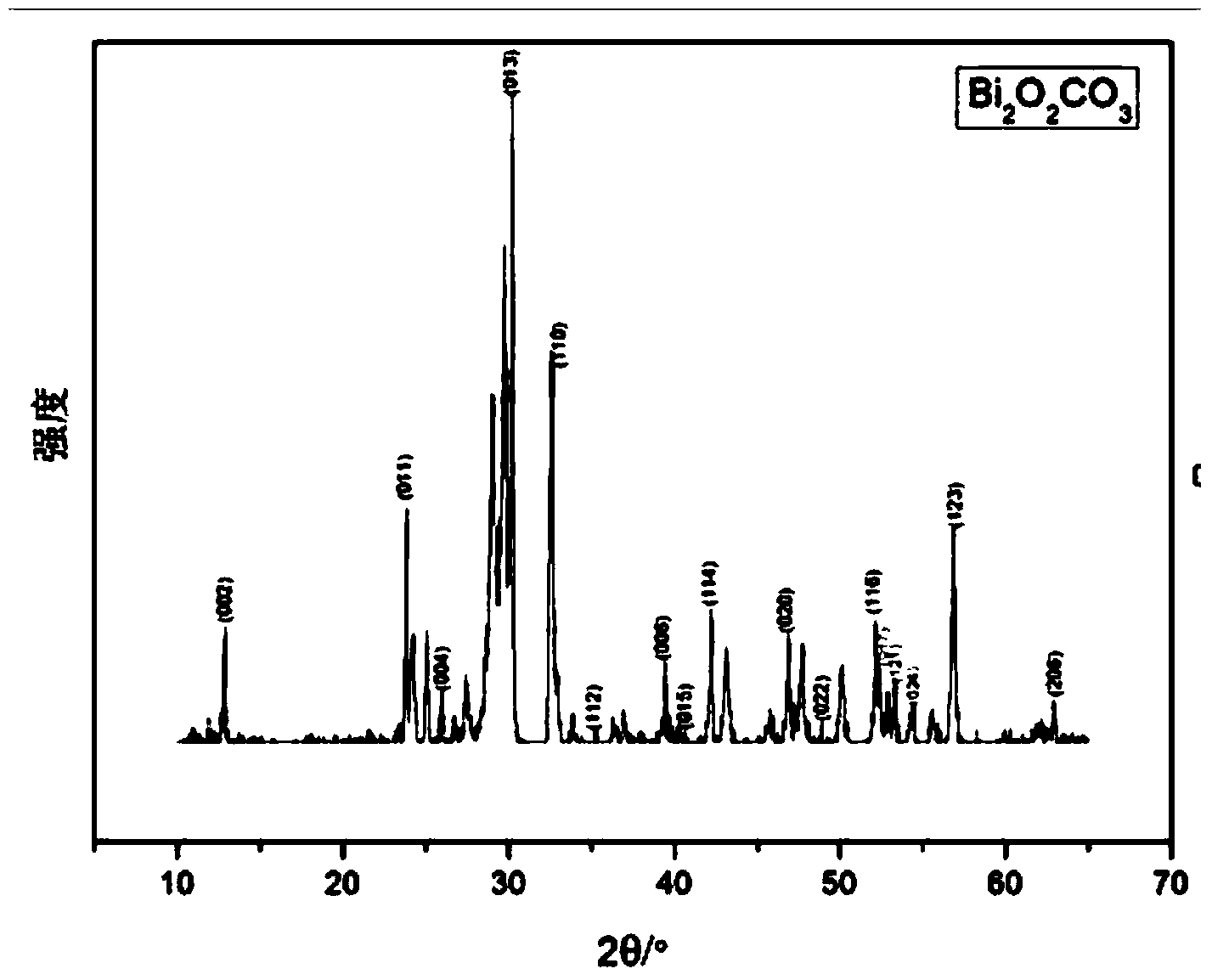

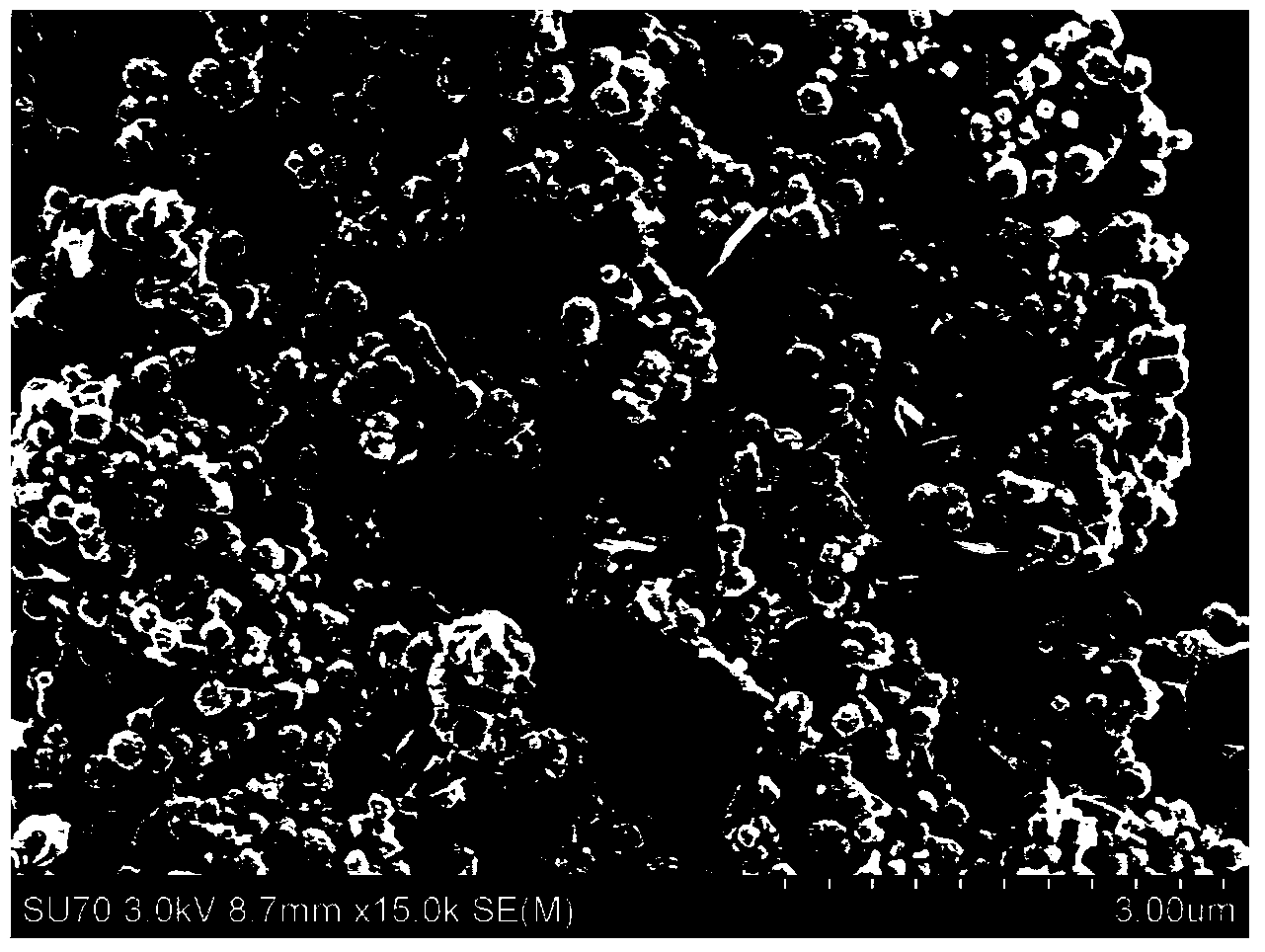

Preparation method and product of bismuth oxycarbonate microspheres

A technology of bismuth oxycarbonate and microspheres, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of rarity, decreased dispersion performance, agglomeration of bismuth oxycarbonate nanoparticles, etc., and achieves a simple preparation process and low cost. , the effect of easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

[0026] 1) Weigh 5.1 mmol of tetrabutyl titanate and add it dropwise to deionized water to control the concentration of tetrabutyl titanate to 0.4 mol / L.

[0027] 2) Weigh 6.8mmol of bismuth nitrate pentahydrate, add it to the suspension prepared in step 1), and stir well

[0028] 3) Weigh 0.02 mol potassium hydroxide, dissolve it in ionized water, control the concentration of potassium hydroxide to 2.0 mol / L, and stir for at least 30 minutes.

[0029] 4) Under agitation, the potassium hydroxide solution prepared in step 3) is added dropwise to the suspension prepared in step 2) at a rate of 30 drops per minute, and is dispersed after sufficient stirring and ultrasonic vibration.

[0030] 5) Add the suspension prepared in step 4) to the inner bladder of the reactor. Use deionized water to adjust its volume to account for 4 / 5 of the inner tank volume of the reactor to obtain a reaction precursor suspension. At this time, the molar ratio of Bi / Ti in the reaction precur...

Example Embodiment

[0032] Example 2

[0033] 1) Weigh 5.1 mmol of tetrabutyl titanate and add it dropwise to deionized water to control the concentration of tetrabutyl titanate to 0.5 mol / L.

[0034] 2) Weigh 6.8mmol of bismuth nitrate pentahydrate, add it to the suspension prepared in step 1), and stir well

[0035] 3) Weigh 0.02 mol potassium hydroxide, dissolve it in ionized water, adjust the concentration of potassium hydroxide to 1.8 mol / L, and stir for at least 30 minutes.

[0036] 4) Under stirring, the potassium hydroxide solution prepared in step 3) is added dropwise to the suspension prepared in step 2) at a rate of 40 drops per minute, and the solution is dispersed after sufficient stirring and ultrasonic vibration.

[0037] 5) Add the suspension prepared in step 4) to the inner bladder of the reactor. Use deionized water to adjust its volume to account for 4 / 5 of the inner tank volume of the reactor to obtain a reaction precursor suspension. At this time, the molar ratio of Bi / Ti in the reac...

Example Embodiment

[0039] Example 3

[0040] 1) Weigh 5.1 mmol of tetrabutyl titanate and add it dropwise to deionized water to control the concentration of tetrabutyl titanate to 0.6 mol / L.

[0041] 2) Weigh 6.8mmol of bismuth nitrate pentahydrate, add it to the suspension prepared in step 1), and stir well

[0042] 3) Weigh 0.02 mol potassium hydroxide, dissolve it in ionized water, control the concentration of potassium hydroxide to 2.0 mol / L, and stir for at least 30 minutes.

[0043] 4) Under agitation, the potassium hydroxide solution prepared in step 3) is added dropwise to the suspension prepared in step 2) at a rate of 30 drops per minute, and is dispersed after sufficient stirring and ultrasonic vibration.

[0044] 5) Add the suspension prepared in step 4) to the inner bladder of the reactor. Use deionized water to adjust its volume to account for 4 / 5 of the inner tank volume of the reactor to obtain a reaction precursor suspension. At this time, the molar ratio of Bi / Ti in the reaction precur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap