Method for culturing microalgae and method for producing grease

A technology of microalgae and algae liquid, applied in the field of microalgae cultivation, can solve the problems of unfavorable clear liquid, increased cost, and influence on the vitality of microalgae, and achieve the effect of simple operation and normal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

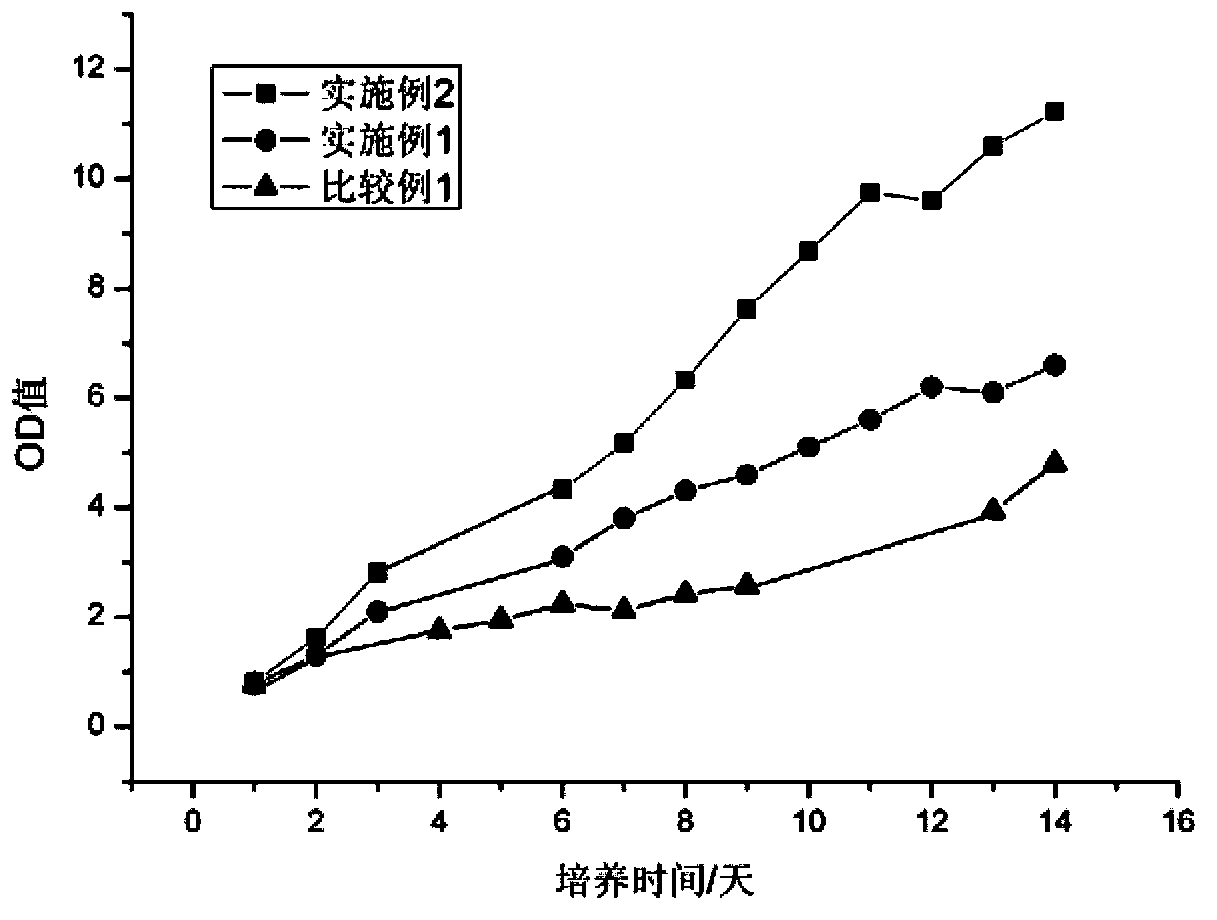

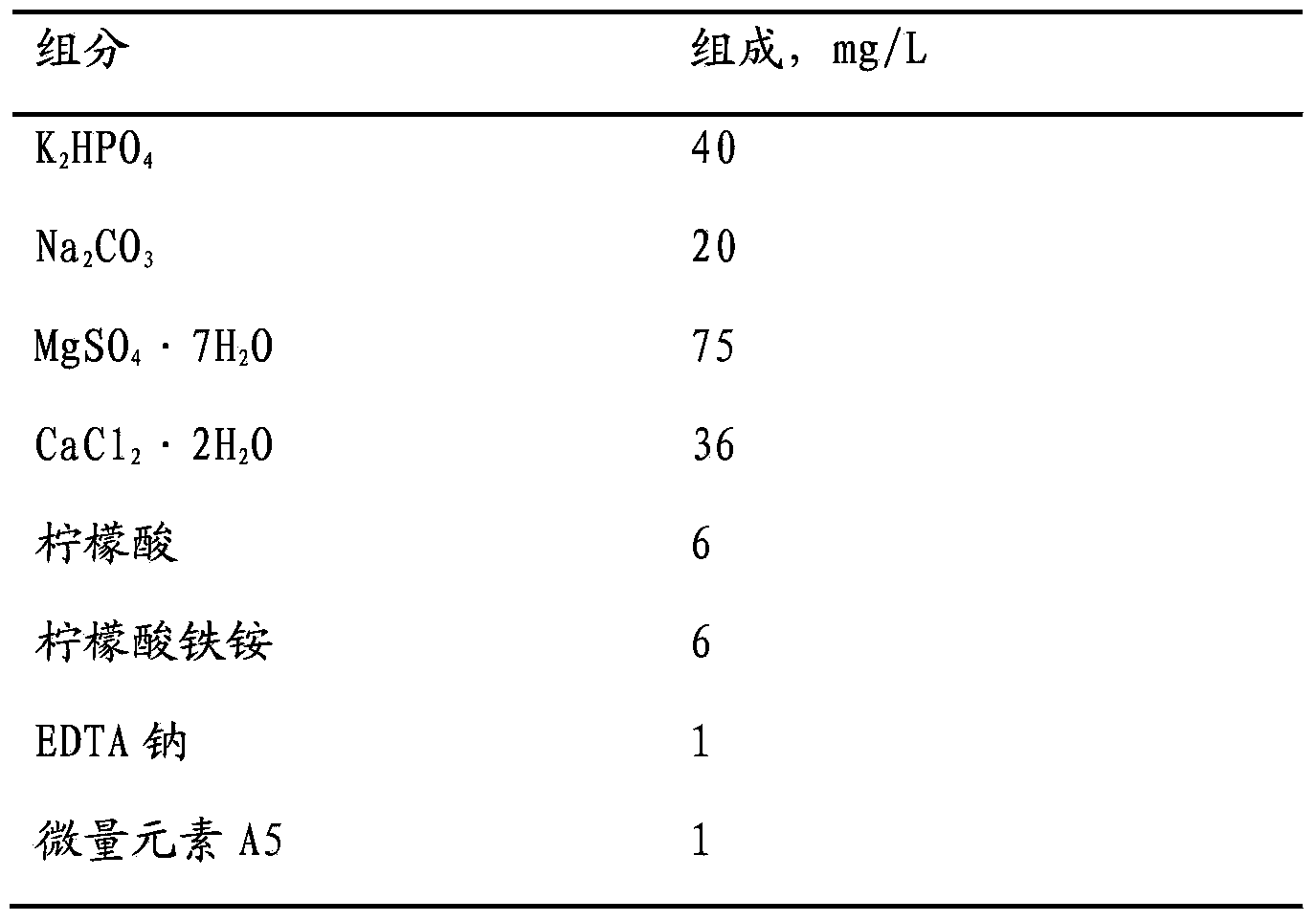

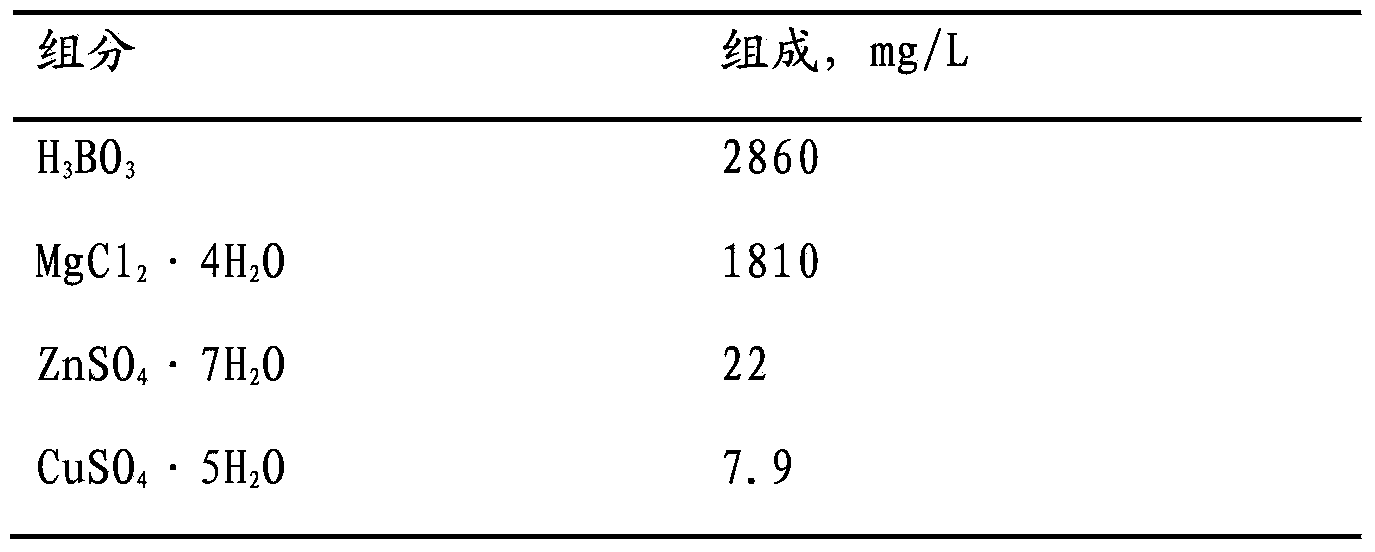

[0044] The cultivation of Chlorella is carried out by adopting the two-stage expanded basic technological process. Primary inoculation culture: 1L glass triangular flask filled with about 700ml medium, the medium is BG11 medium (Table 1), primary inoculation medium uses urea as nitrogen fertilizer, the N content of the algae liquid after inoculation is 40mmol / L, control the light And the temperature is suitable, and 2% (v / v) CO is introduced 2 / Air mixed gas is used for aeration culture, and the mixed gas is filtered and purified by filter membrane. Detect the OD value of the algae liquid. When the OD value of the algae liquid reaches more than 5, the secondary expansion culture can be carried out. Secondary expansion culture: The expansion culture is carried out in a 5L glass triangular flask, filled with 3-4L medium (the mother liquid of the medium is sterilized by high pressure, high temperature or boiled, and the culture water is filtered and sterilized tap water), and th...

Embodiment 2

[0046] The culture of chlorella, method is the same as example 1, and difference is that the N content of algae liquid after inoculation is 66mmolg / L. Growth curve see figure 1 .

Embodiment 3

[0048] The culture of chlorella, method is the same as example 1, and difference is that the N content of algae liquid after inoculation is 100mmol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sedimentation rate | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com