Thermal insulation method of silica brick hot blast stove

A hot blast stove and silica brick technology, applied in the field of air supply system and hot blast stove system, can solve the problems of ineffective cooling, safety risks, long oven time, etc., to reduce energy consumption, simple and easy operation, Guaranteed uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

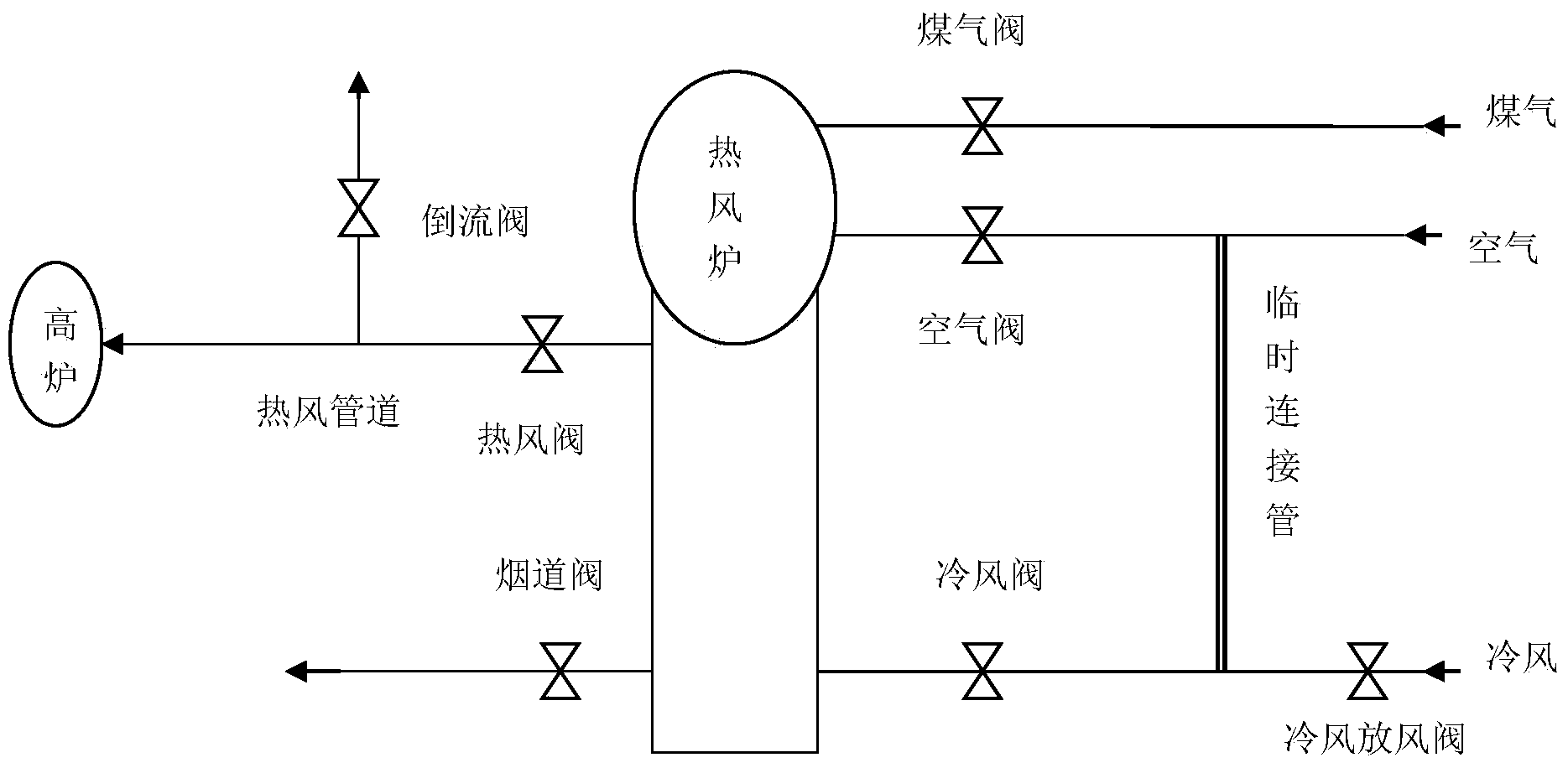

[0019] see figure 1 , the method provided by the invention comprises circulation furnace method and reverse blowing furnace method, specifically:

[0020] The circulation furnace method includes:

[0021] Step 1: Open the air valve and gas valve after opening the flue valve;

[0022] Step 2: Adjust the flow of air and gas to burn the furnace. The flue gas flow enters the flue from the vault of the hot blast stove through the lower part of the hot blast stove and is discharged into the air from the chimney;

[0023] Step 3: When the temperature of the vault reaches the warning temperature of 1350°C-1400°C or the temperature of the flue reaches the warning temperature of 420°C during the firing process, stop the firing and keep warm;

[0024] Step 4: After keeping warm for a period of time, when the temperature of the vault drops to 750°C, start to burn the furnace, and repeat the first to third steps;

[0025] Step 5: After repeated firing, the temperature of the vault rises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com