System and method for supplying steam to RH refining furnace

A refining furnace, steam technology, applied in pipeline system, gas/liquid distribution and storage, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

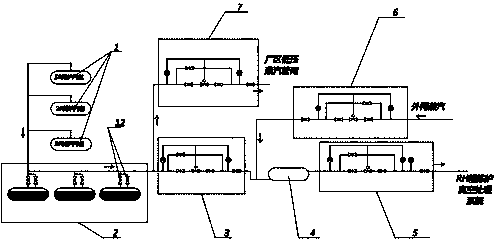

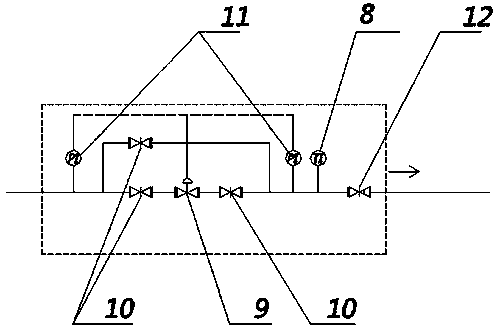

[0025] Refer to the attached drawings. The arrow direction in the figure is the direction of steam flow. A system for supplying steam to the RH refining furnace includes a self-produced steam supply pipeline and an external steam supply pipeline. The self-produced steam supply pipeline includes several converter steam Package 1, heat accumulator group 2, regulating valve group, dewatering steam drum 4 and temperature sensor 8. The converter steam drums are connected in parallel and then connected to the gas supply pipeline. The heat accumulator group includes three heat accumulators and several check valves. Valve 12, three heat accumulators are connected in parallel and connected to the gas supply pipeline. Each heat accumulator is equipped with a check valve at the inlet and outlet to prevent the steam entering the heat accumulator and the steam discharged from the heat accumulator from flowing back. The regulating valve group includes a first regulating valve group 3 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com