Hydrogen/oxygen energy generator

A generator and oxygen generation technology, applied in the chemical industry, cells, climate sustainability, etc., can solve the problems of poor circulation of electrolyte, power consumption of electrode plate heating, and inability to dissipate heat in time, so as to facilitate industrial mass production, Improve the electricity-to-hydrogen ratio and overcome the low efficiency of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

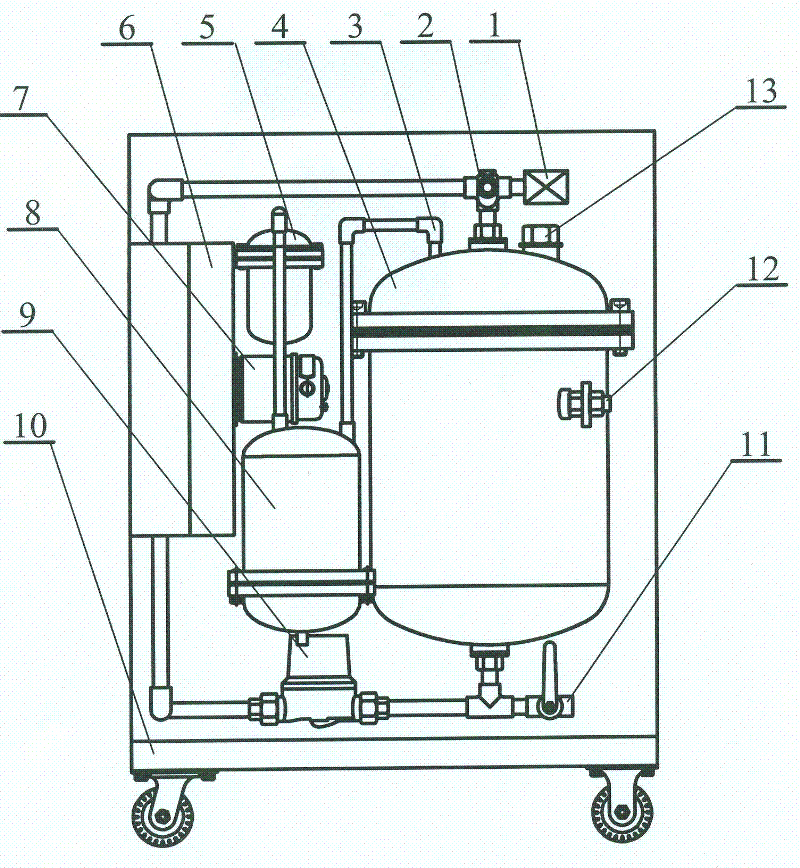

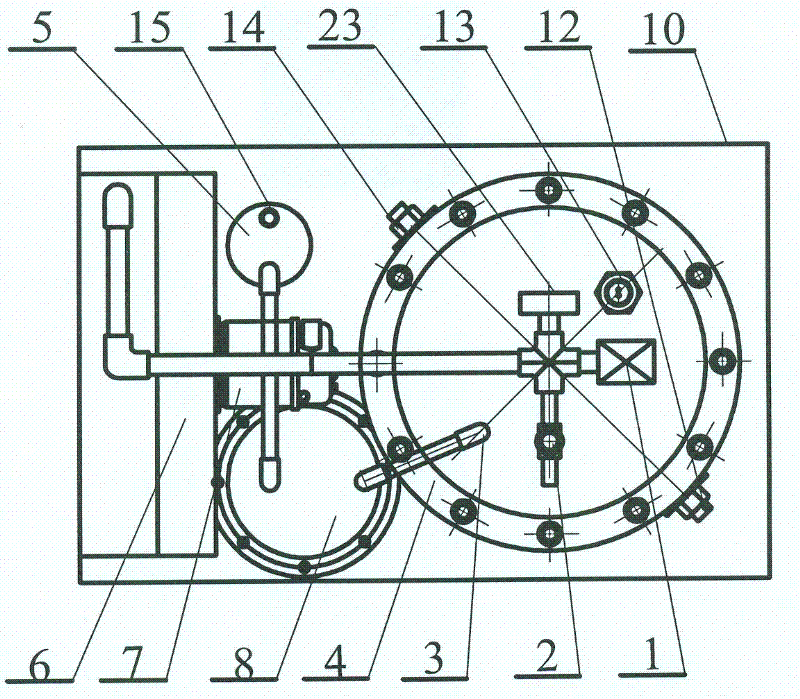

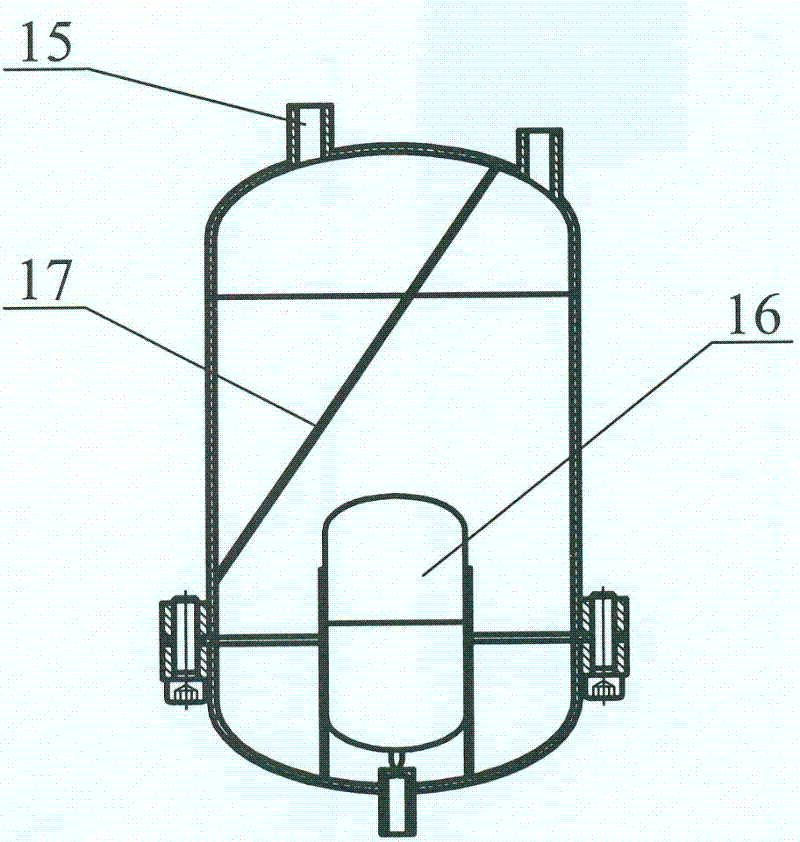

[0021] Combine below Figure 1~5 The specific structure of the present invention will be further described. The hydrogen-oxygen energy generator includes a body 10, a hydrogen and oxygen generating tank 4 assembled on the body 10 with a float level gauge 13, a water replenishment check valve 2 and a safety valve 1, a gas-liquid separation tank 8, and an anti-tempering tank 5. Circulating water pump 9, radiator 6, pressure switch 23, and high-frequency DC pulse power supply (not shown in the figure) connected by wires. Wherein the specifications and shapes of the body 10 and the hydrogen and oxygen generating tank 4 should be selected according to actual use requirements and relevant standards. Float level gauge 13, replenishment check valve 2, safety valve 1, circulating water pump 9, radiator 6, anti-temper tank 5 and pressure switch 23 etc. adopt commonly used commercially available parts. The hydrogen and oxygen generation tank 4 adopts a new design, and its tank body is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com