Self-soaking type oil applying machine for chemical fibers

An oil machine and chemical fiber technology, which is applied in the field of chemical fiber manufacturing, can solve problems such as poor oiling uniformity and stability, difficulty in meeting the requirements of chemical fiber friction, and difficulty in achieving complete lubrication of chemical fibers, so as to improve oiling stability and save resources. , to avoid the effect of uneven oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

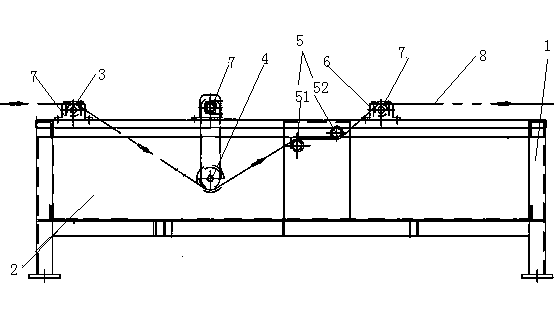

[0015] As shown in the figure, a chemical fiber self-immersed oiling machine of the present invention includes a support 1, and an oil tank 2 is arranged inside the support 1, and the oil tank 2 is a square groove. The first guide roller 3, the dipping roller 4, the bleeding roller group 5 and the second guide roller 6 are provided in sequence to the right; the first guide roller 3 is fixed on the leftmost end of the top of the support 1, and the first guide roller The wire roller 3 is connected with a motor 7; the silk dipping roller 4 is located inside the support 1 and fixed at the bottom of the oil tank 2, and the top of the silk dipping roller 4 is connected with a motor 7; the bleeding roller group 5 is located at the support 1 inside, fixed at the top position of the top of the oil tank 2, its horizontal position is lower than the first guide roller 3, and the bleedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com