Ultraviolet-proof finishing method of fabric for umbrellas

An anti-ultraviolet and ultraviolet technology, applied in the field of anti-ultraviolet finishing of umbrella fabrics and the treatment of umbrella fabrics, can solve the problems affecting the application of anti-ultraviolet fabrics, unstable anti-ultraviolet effect, affecting the appearance of fabrics, etc. Ultraviolet rays, beautiful and multi-faceted needs, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

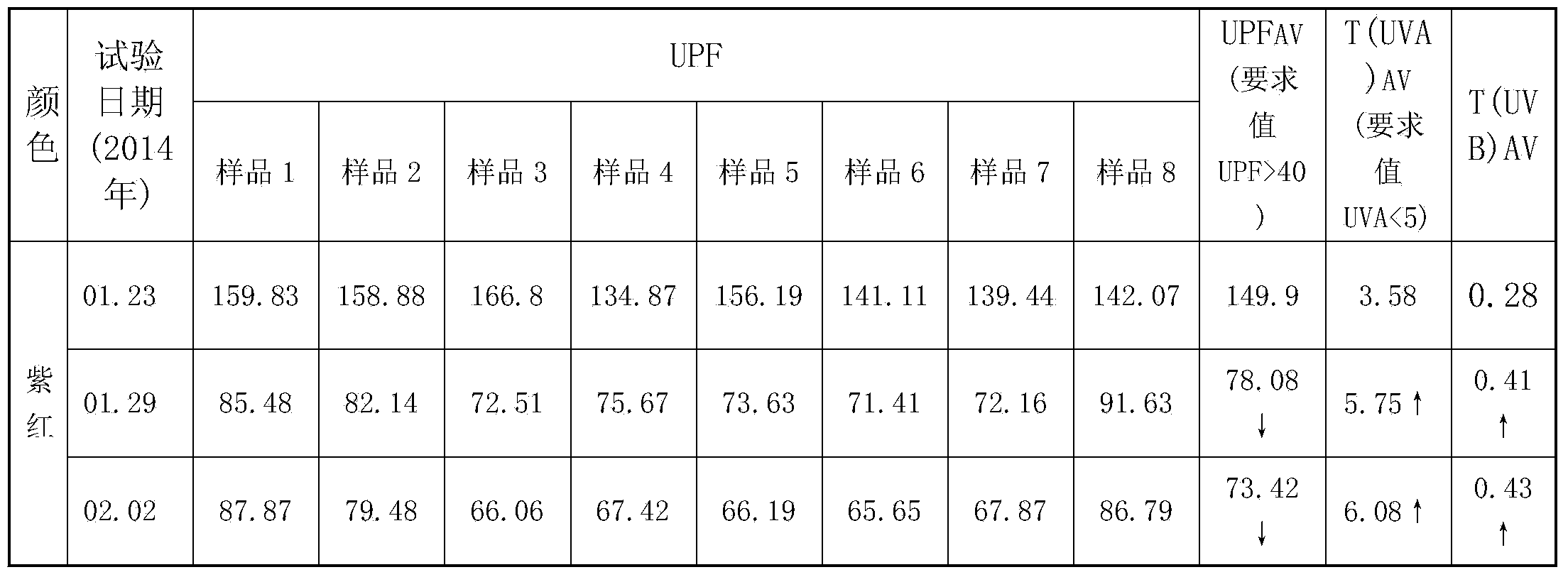

Embodiment 1

[0024] A kind of anti-ultraviolet finishing method of umbrella fabric of the present invention, umbrella fabric gray cloth adopts 190T cationic fabric (being commonly called as chameleon), handles with fabric gray cloth 1000 meters / cylinder, and carries out according to the following steps:

[0025] 1) Desizing

[0026] Use liquid alkali desizing method to remove the size on the gray cloth: add 4wt% liquid alkali and 0.8wt% refining agent into water to make lye, pour the lye into a dyeing pool, control the temperature at 100°C, and make the cloth in the dyeing process Cycle 4 times in the pool, 10 seconds each time;

[0027] 2) Add dye to the dye vat

[0028] According to the design requirements, add the dye of the corresponding color in the dye vat;

[0029] 3) Add water-based nano-ultraviolet shielding agent water dispersion in the dye vat, described water-based nano-ultraviolet shielding agent water dispersion is by weight ratio by 30 parts of ionized water, 0.3 part of d...

Embodiment 2

[0050] A kind of anti-ultraviolet finishing method of umbrella fabric, umbrella fabric gray cloth adopts 190T cationic fabric (being commonly called as chameleon), processes with fabric gray cloth 1000 meters / cylinder, and carries out according to the following steps:

[0051] 1) Desizing

[0052] Use liquid alkali desizing method to remove the size on the gray cloth: add 4wt% liquid alkali and 0.8wt% refining agent into water to make lye, pour the lye into a dyeing pool, control the temperature at 100°C, and make the cloth in the dyeing process Cycle 4 times in the pool, 3 seconds each time;

[0053] 2) Add dye to the dye vat

[0054] According to the design requirements, add the dye of the corresponding color in the dye vat;

[0055] 3) Add water-based nano-ultraviolet shielding agent water dispersion in the dye vat, described water-based nano-ultraviolet shielding agent water dispersion is by weight ratio by 30 parts of ionized water, 0.3 part of dispersant and TiO 3.5 part...

Embodiment 3

[0065] A kind of anti-ultraviolet finishing method of umbrella fabric, umbrella fabric gray cloth adopts 190T cationic fabric (being commonly called as chameleon), processes with fabric gray cloth 1000 meters / cylinder, and carries out according to the following steps:

[0066] 1) Desizing

[0067] Use liquid alkali desizing method to remove the size on the gray cloth: add 4wt% liquid alkali and 0.8wt% refining agent into water to make lye, pour the lye into a dyeing pool, control the temperature at 100°C, and make the cloth in the dyeing process Cycle 4 times in the pool, 7 seconds each time;

[0068] 2) Add dye to the dye vat

[0069] According to the design requirements, add the dye of the corresponding color in the dye vat;

[0070] 3) Add water-based nano-ultraviolet shielding agent water dispersion in the dye vat, described water-based nano-ultraviolet shielding agent water dispersion is by weight ratio by 30 parts of ionized water, dispersant 0.3 part and TiO 3.2 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV shielding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com