Freezing process hole protecting special-shaped pile forming method

A technology of special-shaped pile and freezing method, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of inclined fracture, necking and dislocation of the pile body, so as to ensure the balance of force, reduce the extrusion force, avoid The effect of fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

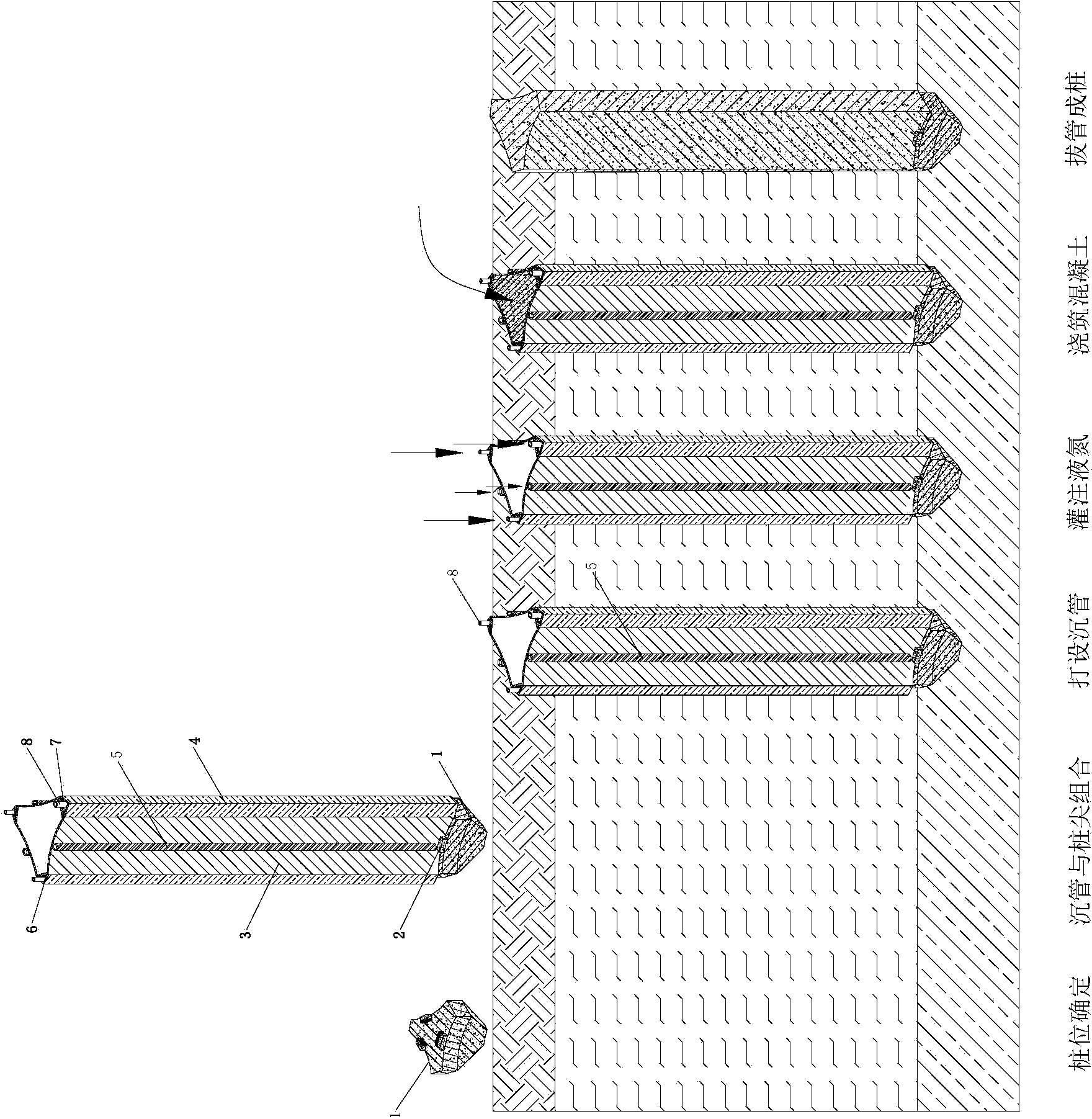

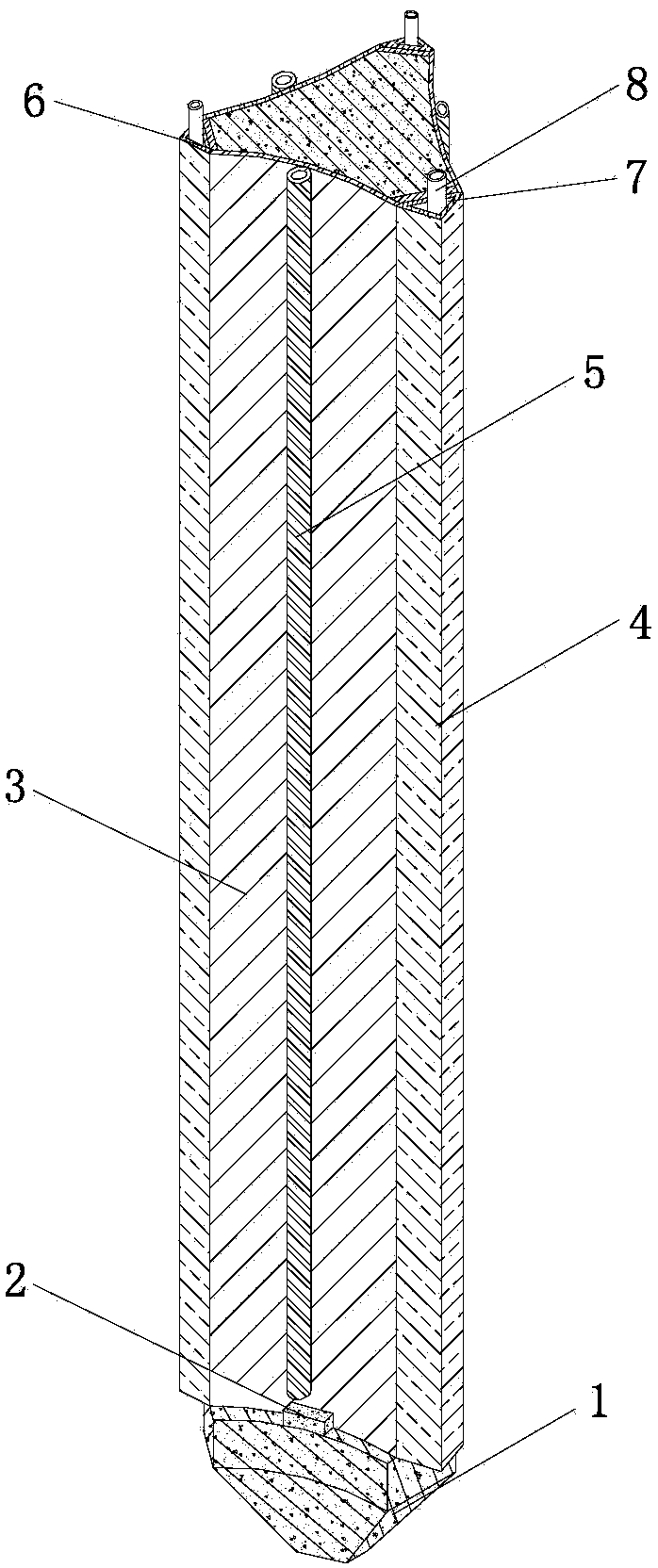

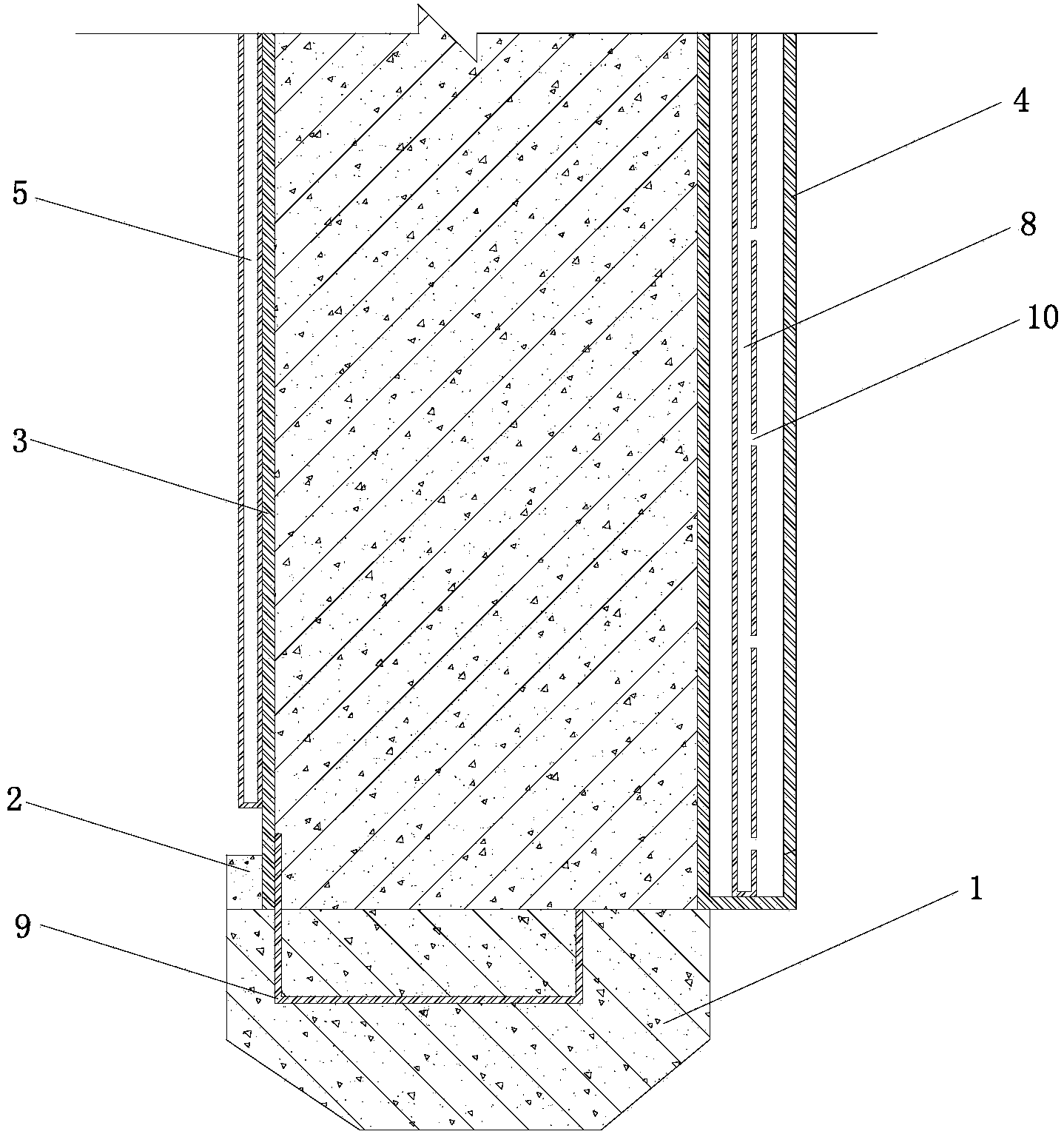

[0036] figure 1 It is a construction flow chart of the pile-forming method of the freezing method special-shaped pile for hole protection of the present invention; figure 2 It is the structural diagram of the freezing method special-shaped pile for hole protection of the present invention; image 3 It is a cross-sectional view of the freezing method special-shaped pile for hole protection of the present invention.

[0037] The prefabricated reinforced concrete pile tip 1 is a reinforced concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com