Small-size cutter-suction boat and pump boat two-parallel and one-series blow filing system and construction method of small-size cutter-suction boat and pump boat two-parallel and one-series blow filing system

A construction method, the technology of the cutter suction ship, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of construction interruption, increased construction cost, low construction efficiency, etc., to achieve system efficiency, reduce equipment damage, and ensure normal operation running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

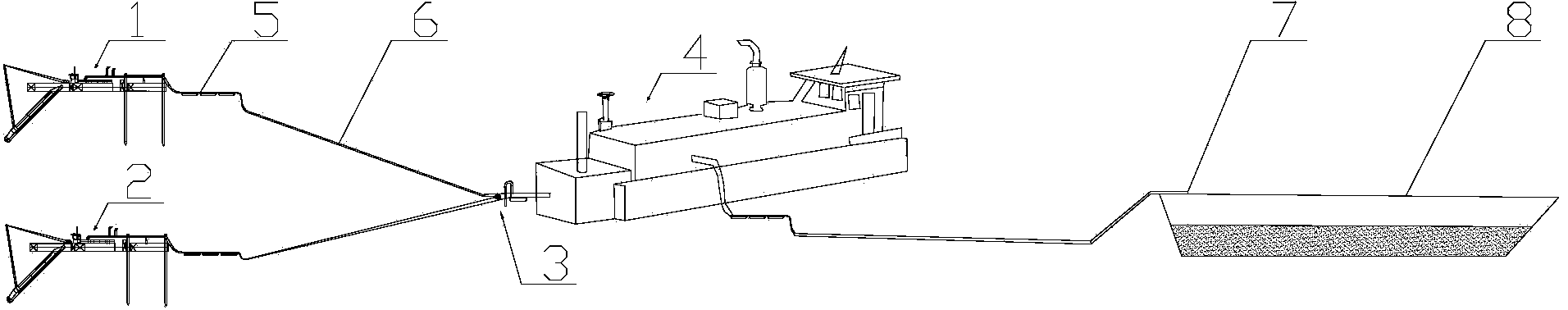

[0032] A small-sized cutter suction ship and pump ship in parallel to blow fill system, the main cutter suction ship and auxiliary cutter suction ship are connected in parallel, and a relay pump ship is connected in series, the main cutter suction ship and auxiliary cutter suction ship are equipped with The pump control switch, the mud discharge pipeline of the pump ship is connected to the mud discharge push field, and the mud discharge pipeline is equipped with an exhaust valve.

[0033] The mud discharge pipelines of the main cutter suction ship and the auxiliary cutter suction ship are connected by an upper mud discharge pipeline and a lower mud discharge pipeline. The mud discharge pipelines of the main cutter suction ship and the auxiliary cutter suction ship are connected in series with the pump ship, and the inlet pressure of the pump ship is 0.5-1.5 bar.

[0034] When carrying out dredging and filling construction operations in this embodiment, the connection of const...

Embodiment 2

[0038] The construction method of two small cutter suction ships and pump ships paralleling one series blowing and filling system uses the main cutter suction ship to establish contact with the auxiliary cutter suction ship and the relay pump ship, and coordinates the operations of vehicle preparation, pump combined construction, and pump off shutdown operations, including the following Construction steps:

[0039] 1. Spare vehicles: When the main cutter suction ship needs to prepare vehicles, the auxiliary cutter suction ship and the relay pump ship are ready; the relay pump ship opens the exhaust valve of the mud discharge pipe;

[0040] 2. Pumping: After the auxiliary cutter suction ship and the relay pump ship are ready, the main cutter suction ship and the auxiliary cutter suction ship are combined with the pump at the same time, and gradually accelerate to the specified speed of the mud pump diesel engine; the mud discharge pipeline of the relay pump ship exhausts After ...

Embodiment 3

[0043] The construction method of small cutter suction boats and pump boats paralleling a series blowing and filling system, using the main cutter suction boat to establish contact with the auxiliary cutter suction boat and the relay pump boat, coordinate the operation of vehicle preparation, pump construction, and pump detachment parking, specific operations Including the following construction steps:

[0044] 1. Start to prepare the vehicle according to the following steps:

[0045] ①Before the system is started, the main cutter suction dredger shall notify the standby truck, and the auxiliary cutter suction dredger and the relay pump ship shall immediately prepare the truck. At the same time, the relay pump ship shall open the exhaust valve on the mud discharge pipe at the rear of the pump ship.

[0046] ② After the auxiliary cutter suction dredger and the relay pump ship are ready, immediately inform the main cutter suction dredger that the preparation is complete and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com