Whole bathroom frame foaming tile floor and manufacturing method thereof

The technology of a ceramic tile floor and a manufacturing method, which is applied in the field of bathroom, can solve the problems of easy falling off of tiles, difficult quality assurance and high labor cost, and achieve the effects of saving construction labor costs, simple and convenient construction, and good sound insulation and heat preservation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is specifically described below in conjunction with specific embodiment and accompanying drawing:

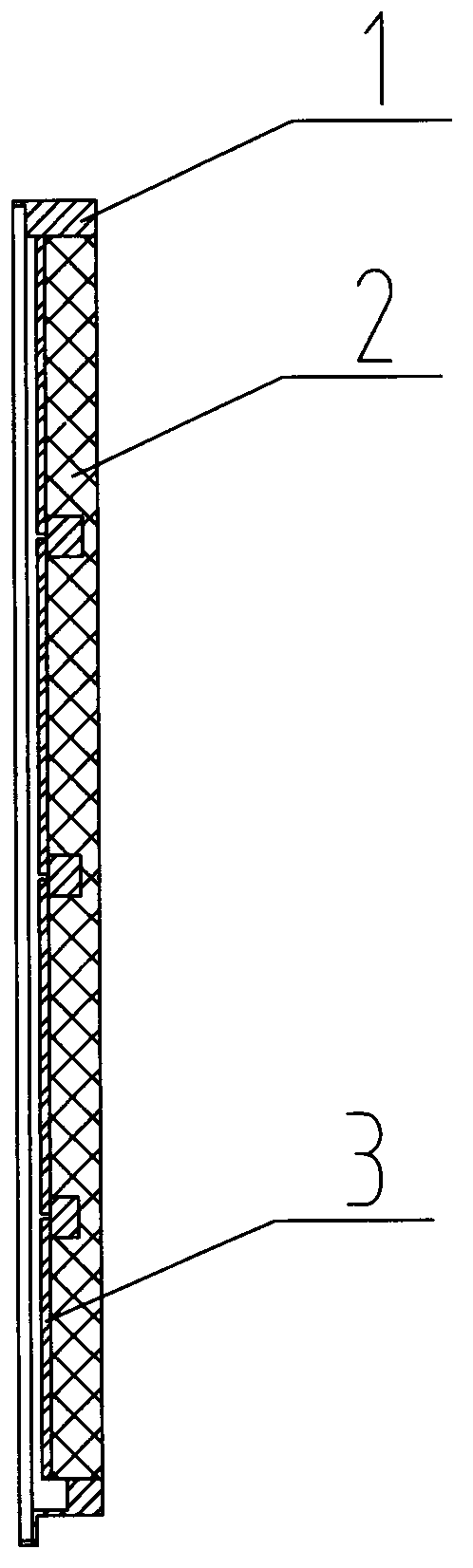

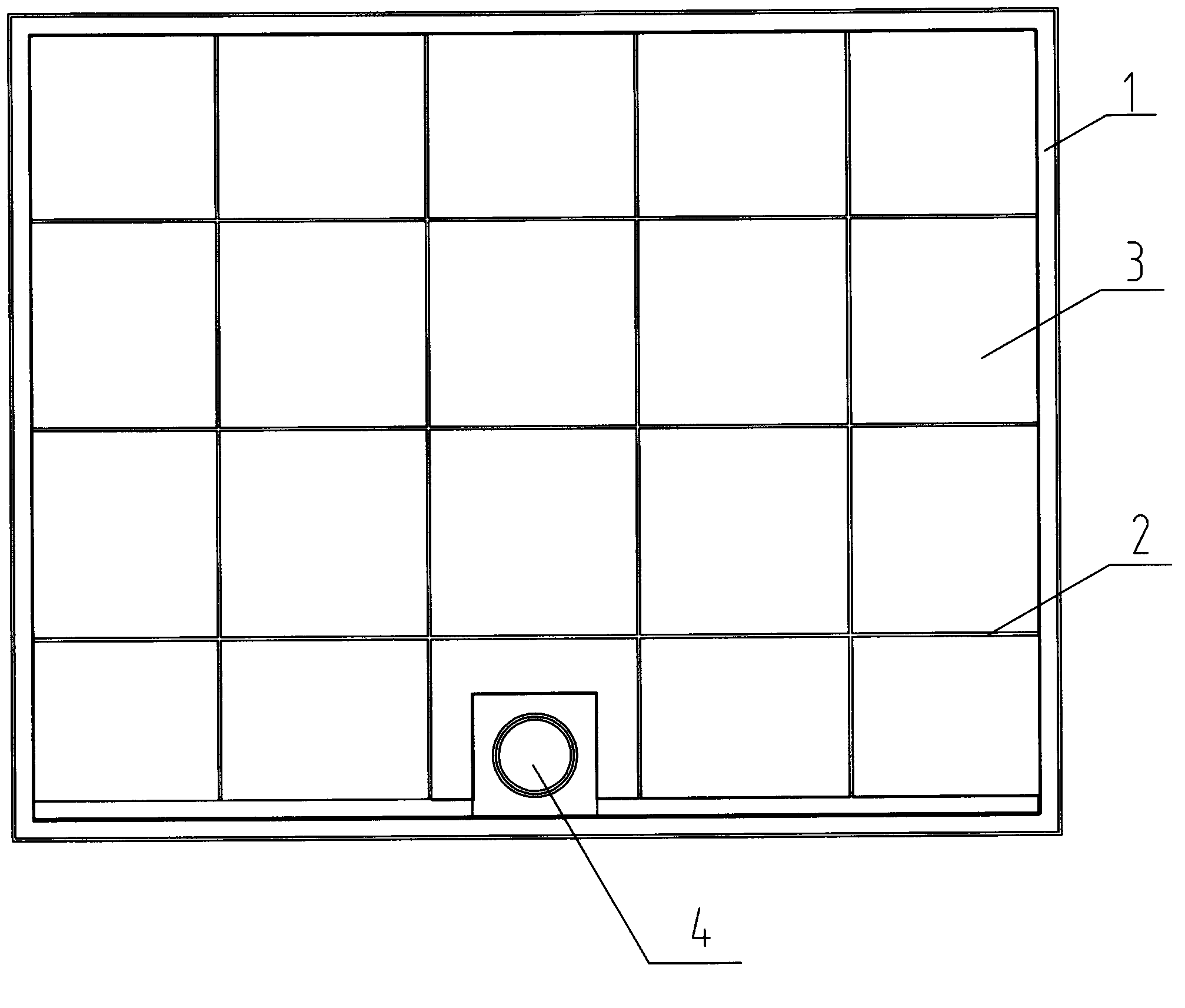

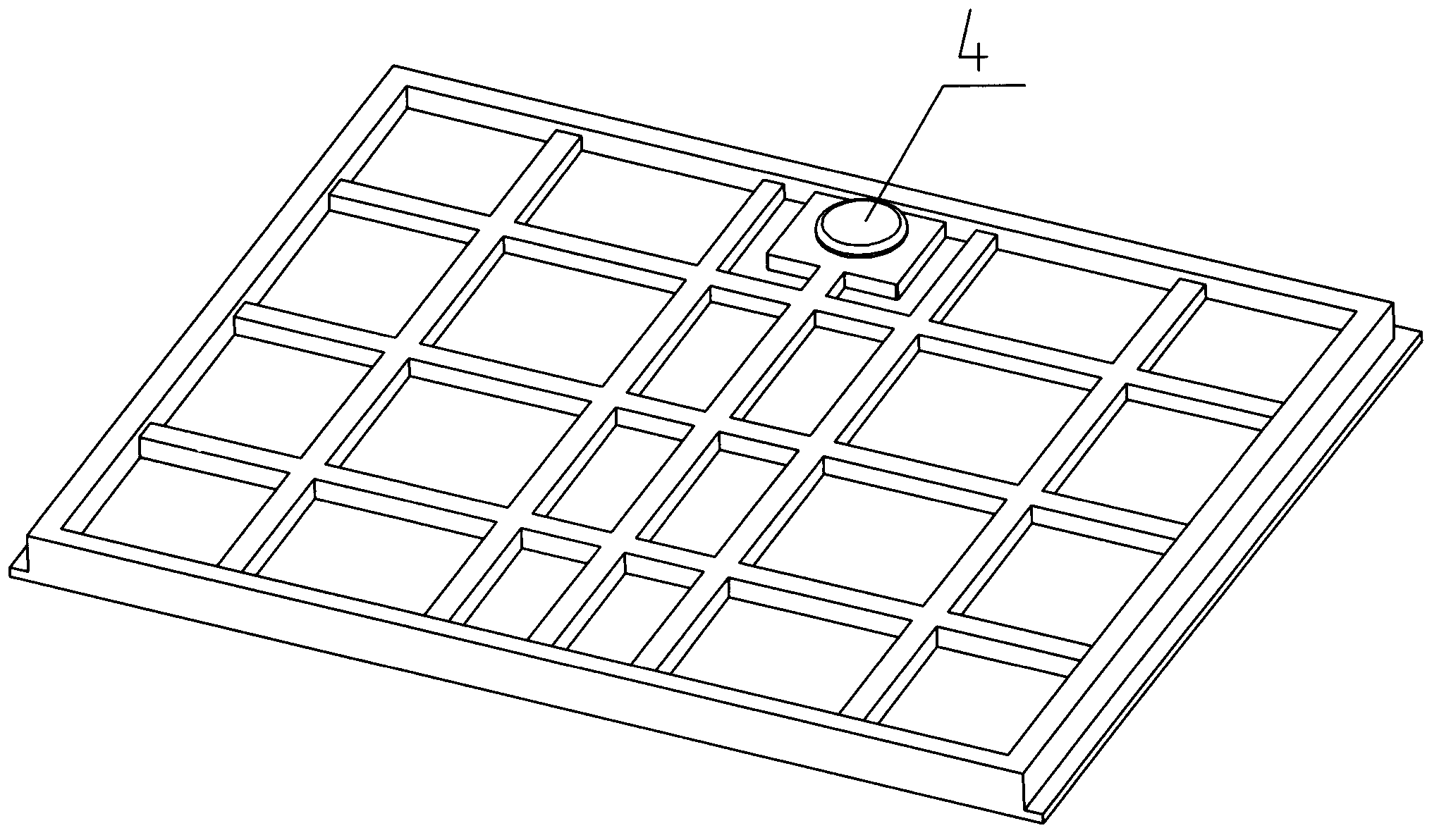

[0018] Such as figure 1 , figure 2 As shown, an integral bathroom frame foam tile floor is composed of a reinforcement frame 1, a polyurethane foam material 2, and tiles 3. The reinforcement frame 1 is a polyester sheet-like film plastic or glass steel or a composite material with a certain strength; Such as image 3 Shown is a three-dimensional view of the reinforcement frame 1. The reinforcement frame 1 is provided with a number of grooves corresponding to and adapted to the tiles. The concave bottom of the grooves is an inclined surface on a plane, so that the floor surface forms a certain inclination after the tiles are installed. surface to drain water; the concave bottom of the groove is higher than the bottom of the reinforced frame, so that when the reinforced frame is placed on the lower cover, the concave bottom of the groove can be conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com