Thermal management system for engine and engineering machine

A thermal management system and construction machinery technology, which is applied in the direction of engine cooling, engine components, machine/engine, etc., can solve the problems of single heat dissipation mode of the engine heat dissipation system, difficulty in adapting to engine working conditions, heat dissipation or heat engine needs, etc., so as to save fans Power, reduce mechanical loss, reduce the effect of mechanical power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

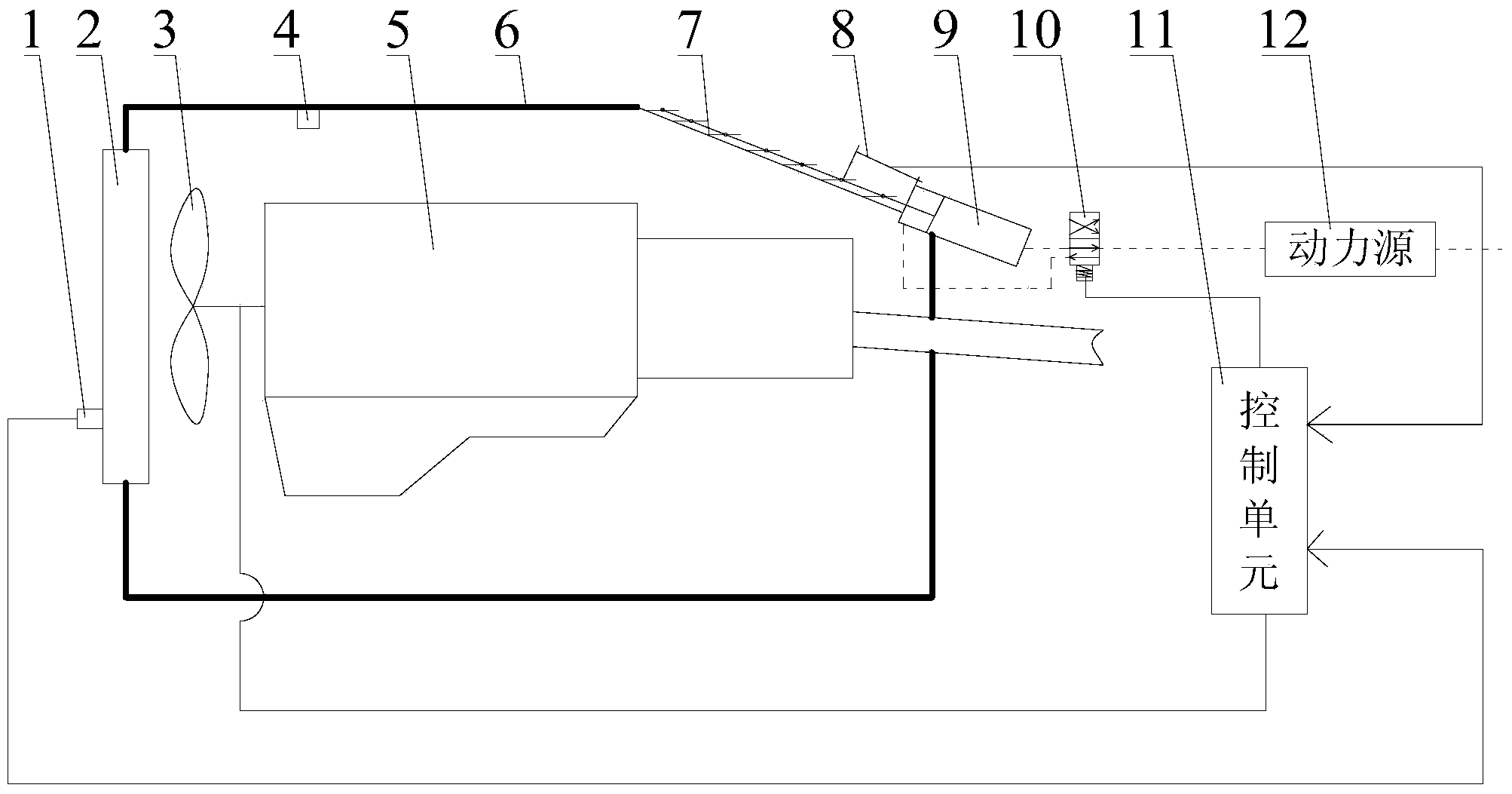

[0037] Please refer to figure 1 , the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] As shown in the figure, the thermal management system for an engine of this embodiment may include a closed engine compartment 6 , a first temperature detection device 1 , a second temperature detection device 4 , an opening adjustment mechanism and a control unit.

[0039] Wherein, the fan 3 can be driven by the engine 5, the specific structure and connection relationship of the engine 5, the fan 3, the radiator 2, and the coolan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com