High-frequency muffler used on automobile intercooler intake pipe

A technology of air intake pipe and muffler, which is applied in the direction of air intake muffler, etc., can solve the problems that the anechoic frequency band cannot cover the frequency range well, the control effect of broadband peak noise is poor, and the anechoic performance does not meet the requirements, etc., and meets the requirements The effect of small restriction, excellent noise reduction performance and small structural size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

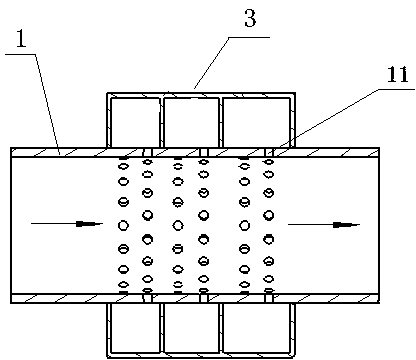

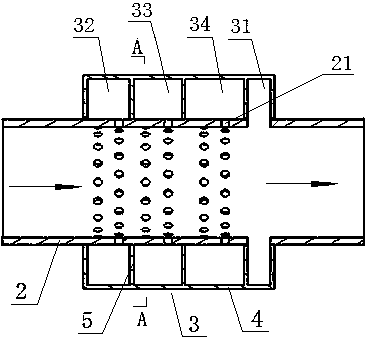

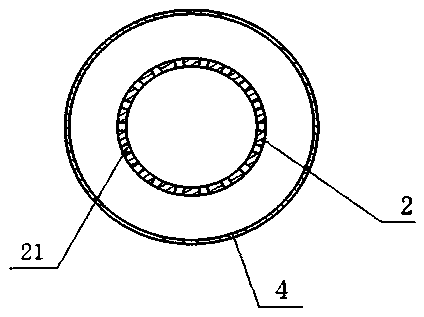

[0019] Example 1: like figure 2 , image 3 , Figure 4 The shown high-frequency muffler used on the intake pipe of the intercooler of an automobile includes a high-frequency noise reduction structure 3 and a main pipe 2 connected to the intake pipe 1 of the intercooler. The intake pipe 1 of the intercooler is divided into two sections, A section of the intake pipe close to the turbocharger is threaded to one end of the main pipe 2, and a section of the intake pipe near the intercooler is threaded to the other end of the main pipe 2; Closed shell 4, the outside of the closed shell 4 is provided with a high-frequency muffler fixing bracket 6, the closed shell 4 is provided with three circular partitions 5 along the radial direction, so that the closed shell 4 along the main pipe 2 The airflow direction of the first resonant cavity 32, the second resonant cavity 33, the third resonant cavity 34 and the expansion cavity 31 are sequentially formed, and the cavity lengths of th...

Embodiment 2

[0021] Example 2: Its main structure and principle are the same as that of Embodiment 1, except that only two partitions 5 are arranged in the closed casing 4, so that the high-frequency noise reduction structure is composed of two resonant cavities and one expansion cavity.

Embodiment 3

[0022] Example 3: Its main structure and principle are the same as that of Embodiment 1, except that four partitions 5 are arranged inside the closed casing 4, so that the high-frequency noise reduction structure is composed of four resonant cavities and one expansion cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com