Analysis system for thermal state performance test data of continuous-casting secondary cooling nozzle

A technology of thermal performance and data, applied in the field of steelmaking and continuous casting, can solve problems such as interference, achieve high integration, ensure accuracy, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

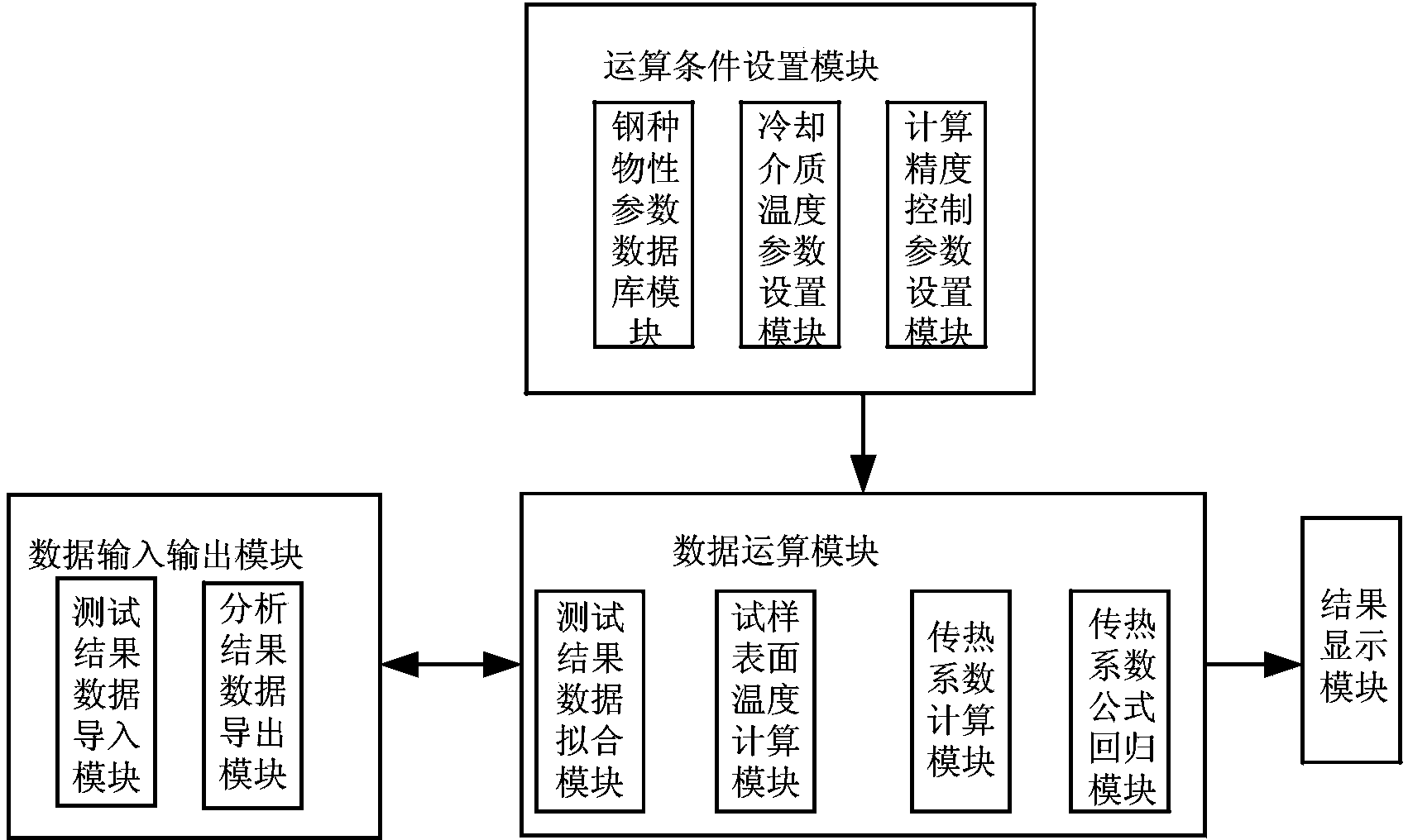

[0030] Such as figure 2 Shown is a structural diagram of a thermal performance test data analysis system for a continuous casting secondary cooling nozzle provided by an embodiment of the present invention.

[0031] Depend on figure 2 It can be seen that in the thermal performance test data analysis system of the continuous casting secondary cooling nozzle provided by the embodiment of the present invention, the data operation module includes a test result data fitting module.

[0032] The test result data fitting module fits the time-temperature data of the thermal state performance test of the tested sample, and performs noise reduction processing on the thermocouple data obtained from the test, so as to facilitate the convergence of the calculation process of the analysis system.

[0033] In the embodiment of the present invention, the data operation module includes a sample surface temperature calculation module and a heat transfer coefficient calculation module, and th...

Embodiment 2

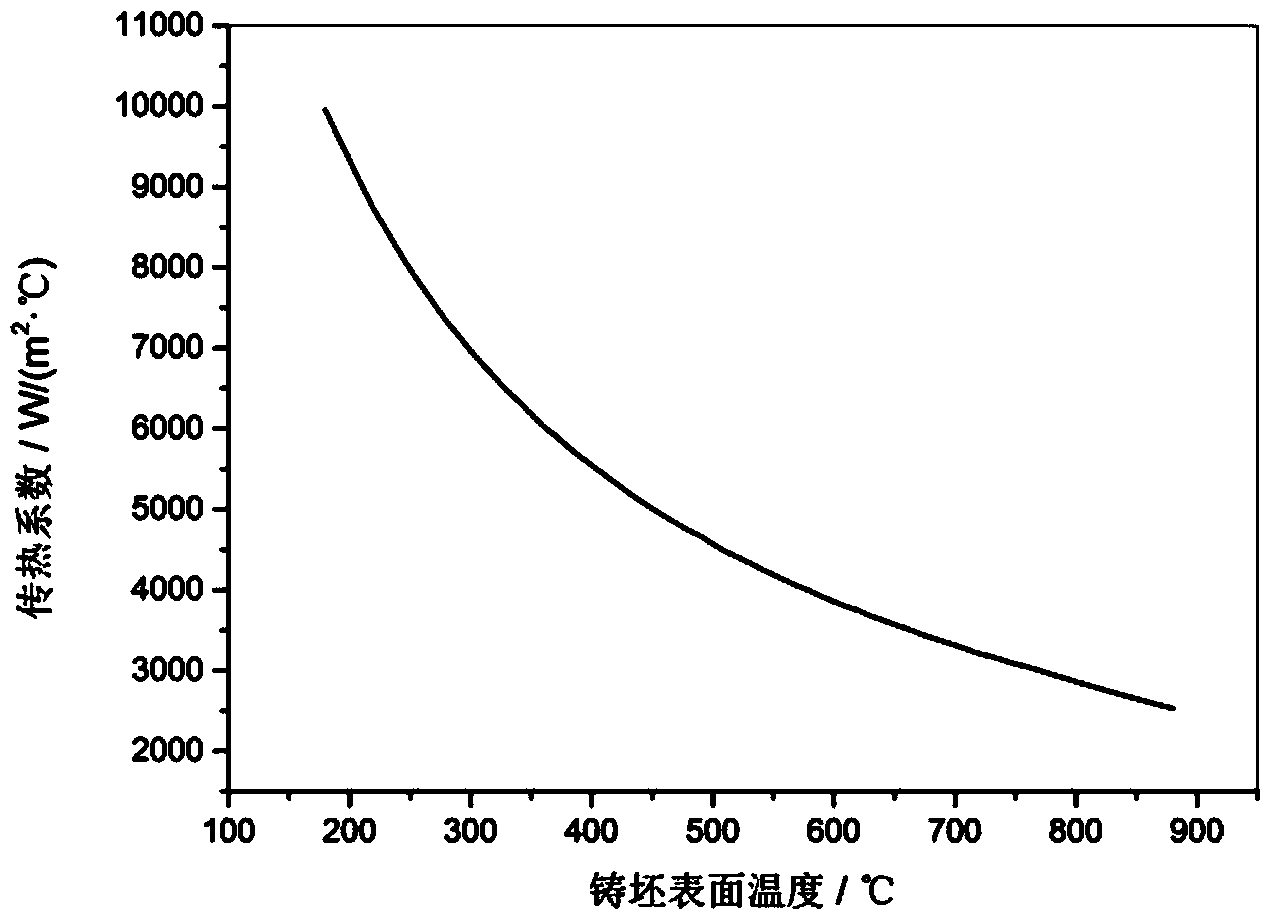

[0040] Embodiment 2 provided by the present invention is a specific application embodiment of the thermal state performance test data analysis system of the continuous casting secondary cooling nozzle provided by the present invention.

[0041] 1. Test nozzle model A, spray angle 110°, installation height 200mm, installation distance 200mm, test air pressure 0.2MPa, test water pressure 0.4MPa, sample steel type is Q235A, and test initial temperature is 880°C.

[0042] Specific steps are as follows:

[0043] 1. Test data import process:

[0044] Import the test result data into the thermal performance test data analysis system of the continuous casting secondary cooling nozzle.

[0045] 2. Operation condition setting process:

[0046] First, select the test steel type as Q235A in the steel physical parameter database; secondly, set the cooling water temperature to 20°C, and the ambient temperature to 20°C; thirdly, set the space step size to 2mm and the time step size to 0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com