Modular permanent magnet vacuum feeder switch

A feeder switch and permanent magnet vacuum technology, applied in the field of feeder switches, can solve problems such as difficult troubleshooting of fault points, cumbersome and complicated replacement of components, etc., to protect contacts from arcing damage and adhesion, and to facilitate maintenance and repair. , volume and weight improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

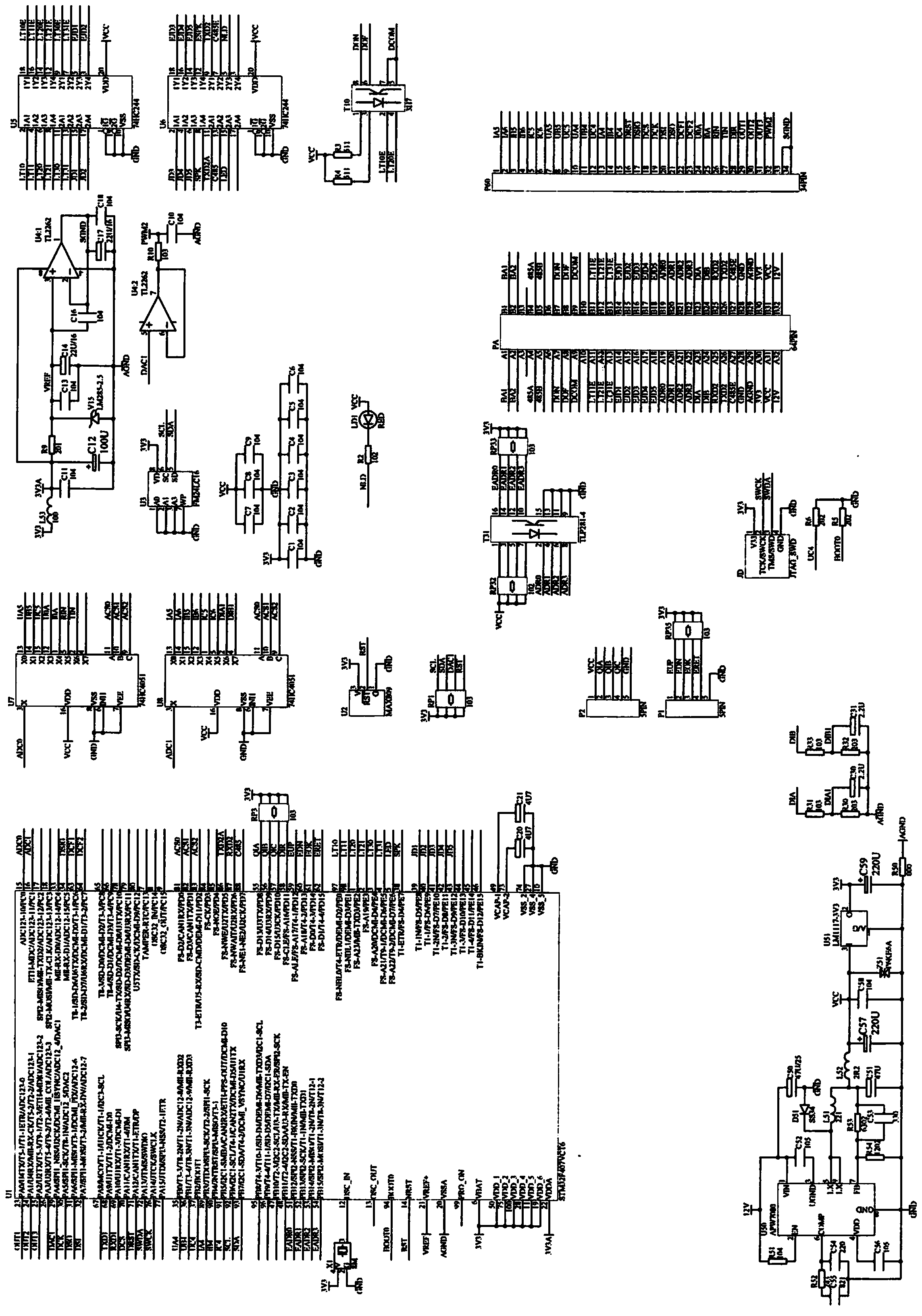

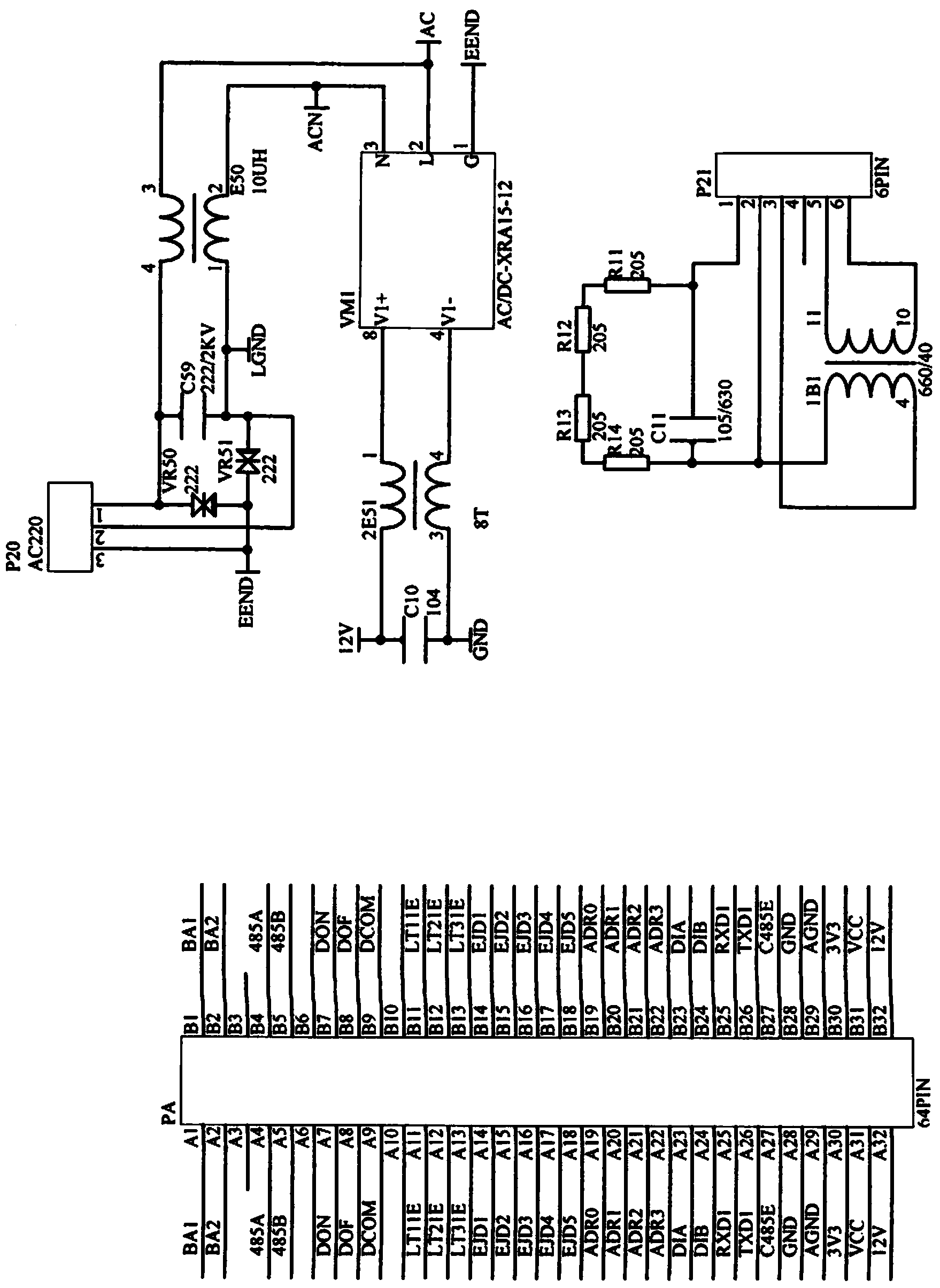

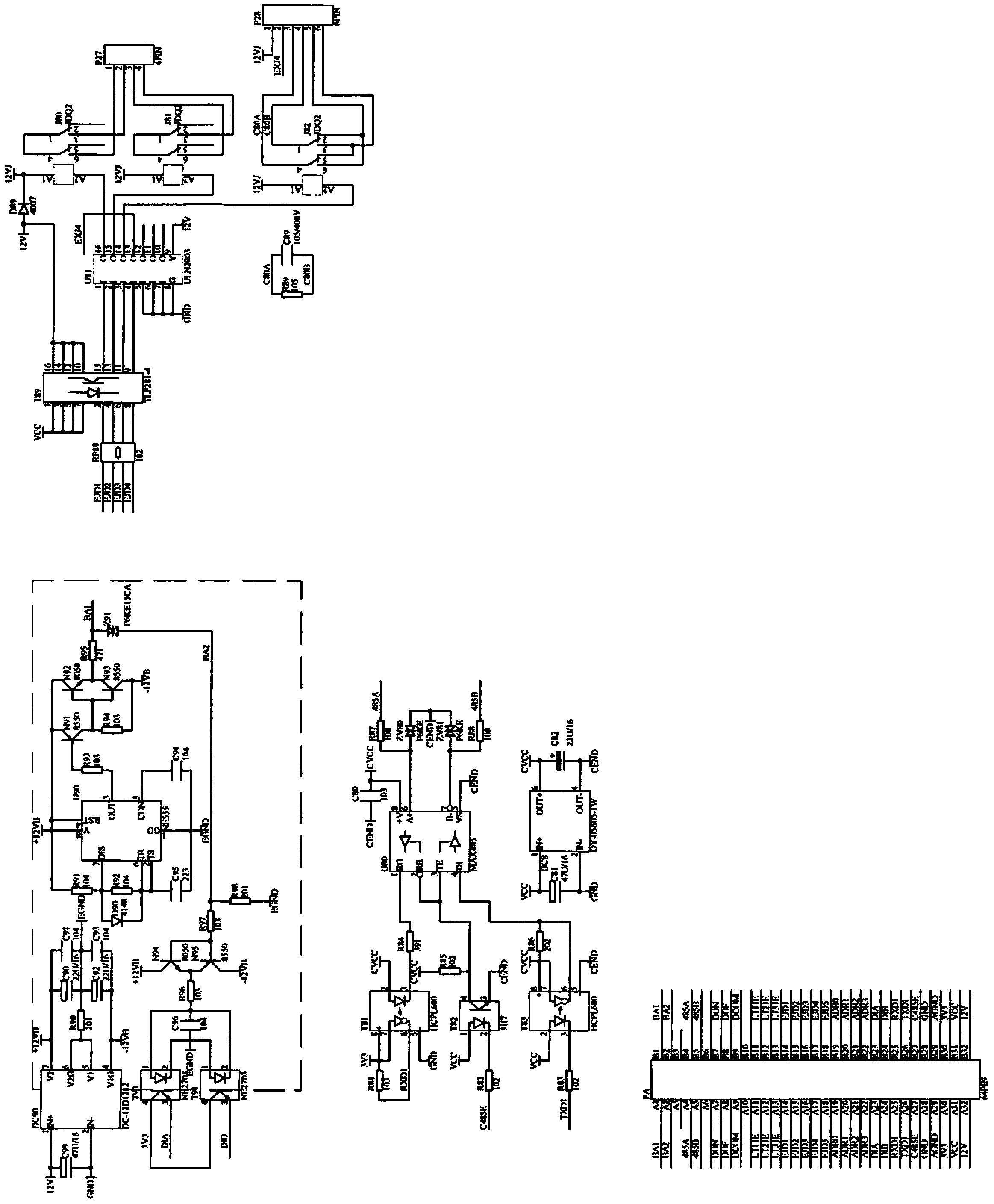

[0043] Such as figure 1 As shown, a modular permanent magnet vacuum feed switch has a switch body, including a circuit breaker 1 and a controller 2 . Such as figure 2 The circuit breaker 1 shown has a circuit breaker housing 3, and the circuit breaker housing 3 is provided with three accommodating cavities sequentially from top to bottom, and each accommodating cavity is provided with a permanent magnet device 4 and a permanent magnet device 4 The vacuum tube 6 connected by the connection mechanism 5 and the current transformer 7 connected with the vacuum tube 6. Such as figure 1 and 5 As shown, the controller 2 has a controller box 8 that matches the circuit breaker housing 3, and wires are connected between the controller box 8 and the circuit breaker housing 3, and are locked to each other by a locking mechanism, as shown in figure 1 As shown, the locking mechanism includes four fastening plates 35 extending toward the circuit breaker case 3 on the side walls I and II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com