Hard coating film and touch panel display device provided with same

A technology for display devices and hard coating films, which can be applied to household appliances, other household appliances, instruments, etc., and can solve problems such as cracks in hard coating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

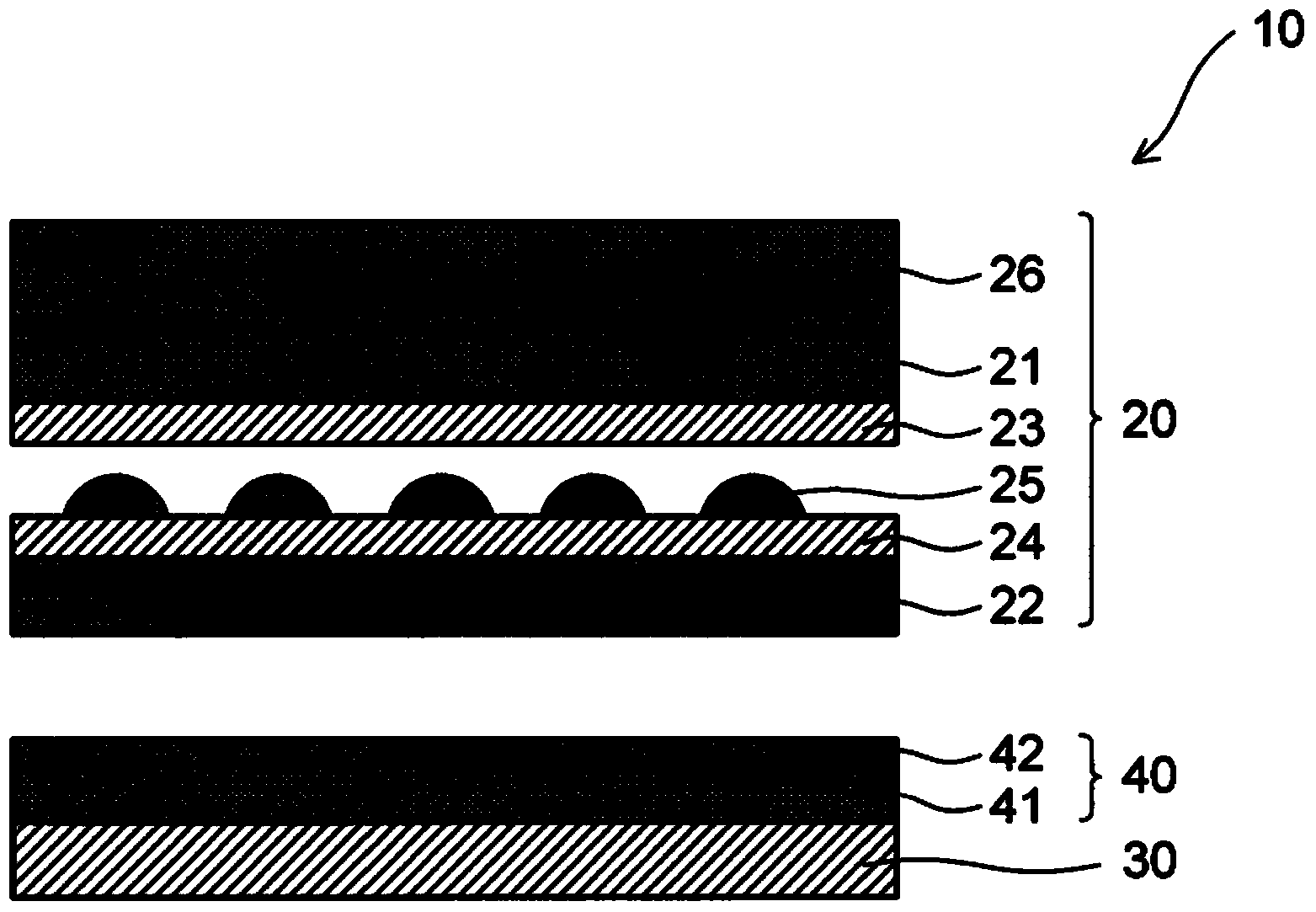

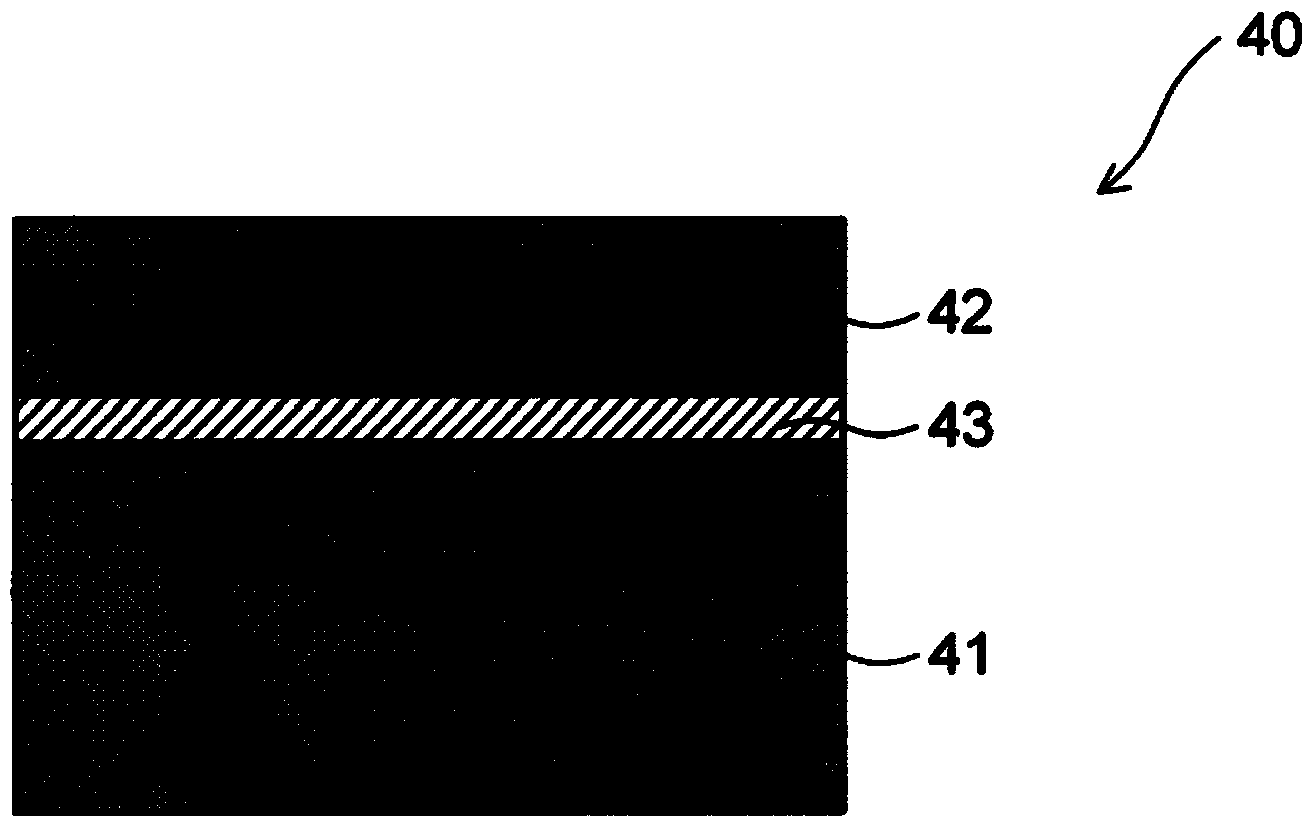

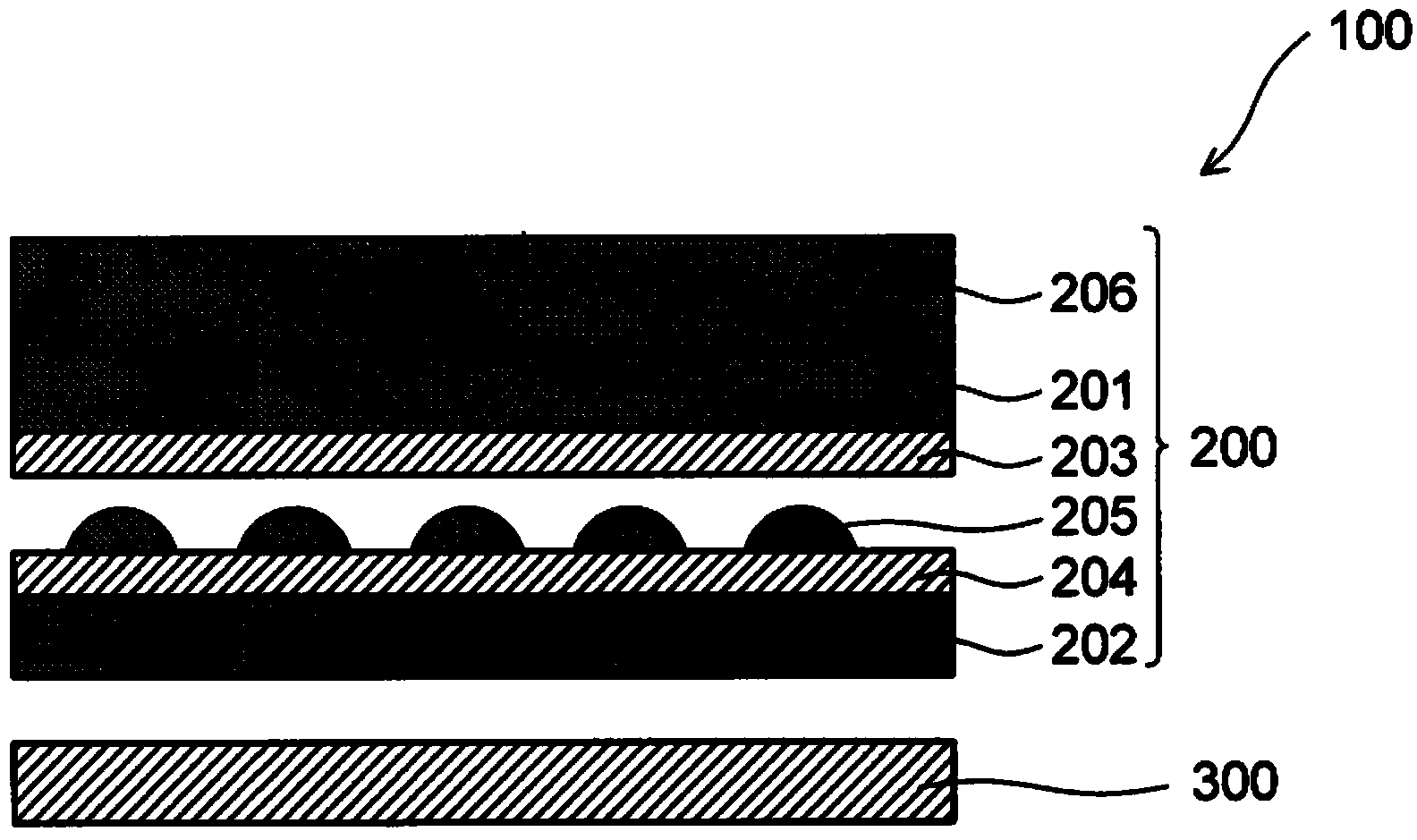

Method used

Image

Examples

Embodiment 1~20

[0275] (Examples 1-20, Comparative Examples 1-18)

[0276] (production of cellulose ester film 1)

[0277] The following materials were sequentially put into a closed container, and after raising the temperature in the container from 20°C to 80°C, the temperature was kept at 80°C and stirred for 3 hours to completely dissolve the cellulose ester. Silica microparticles are dispersed and added to a solution of solvent and a small amount of cellulose ester added in advance. This coating material was filtered using filter paper (Azumi Filter Paper Co., Ltd. product, Azumi Filter Paper No. 244), and coating composition 1 was obtained.

[0278] Cellulose triacetate (acetyl substitution degree 2.95) 100 parts by mass

[0279] 8.7 parts by mass of triphenyl phosphate

[0280] (The content in the cellulose ester film is 8.0% by mass)

[0281]

[0282] Next, the obtained coating composition 1 was cast on a support made of a stainless steel belt at a temperature of 35° C. through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com